2 Reasons Why Your VFD Cable Length Matters

Introduction

In industrial applications, VFD cable length plays a crucial role in ensuring stable operation of both the VFD Drives and the motor. Many common variable frequency drive issues such as VFD overcurrent, VFD overvoltage, insulation breakdown, and motor overheating can be directly traced to improper cable length. This article analyzes why VFD cables must remain within recommended limits, the problems caused by excessive length, and practical solutions to mitigate these risks.

Electrical Problems Caused by Long VFD Cable Length

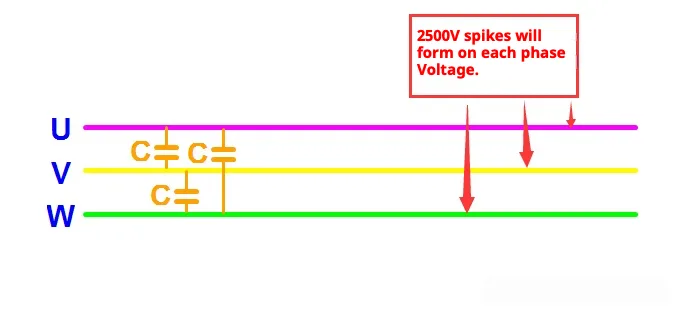

Unlike a standard sinusoidal AC supply, a variable frequency drive outputs PWM (Pulse Width Modulation) signals in the form of rectangular waves. When the VFD cable length is too long, reflected wave phenomena occur, creating high transient voltage spikes.

- For example, at around 100 meters of cable length, peak voltage may reach 1500–2000V.

- These high-frequency VFD harmonic currents and common mode current increase electrical stress on both the drive and the motor.

- Coupling capacitance between the three-phase conductors leads to repeated capacitor discharge, which can cause severe current spikes and trigger VFD overcurrent trip on startup.

Impact of VFD Cable Length on Motor Operation

Excessive VFD cable length also damages the motor in several ways:

- Motor insulation failure: Standard AC motors are designed for insulation levels around 1000V. When spikes exceed 2000V, the insulation can easily break down.

- Motor shaft voltage and bearings: Long cables induce strong shaft voltages and bearing currents, leading to lubricant degradation and premature bearing failure.

- VFD cable length and motor heating: Increased losses result in inverter motor heat, excessive motor temperature, and even permanent motor damage.

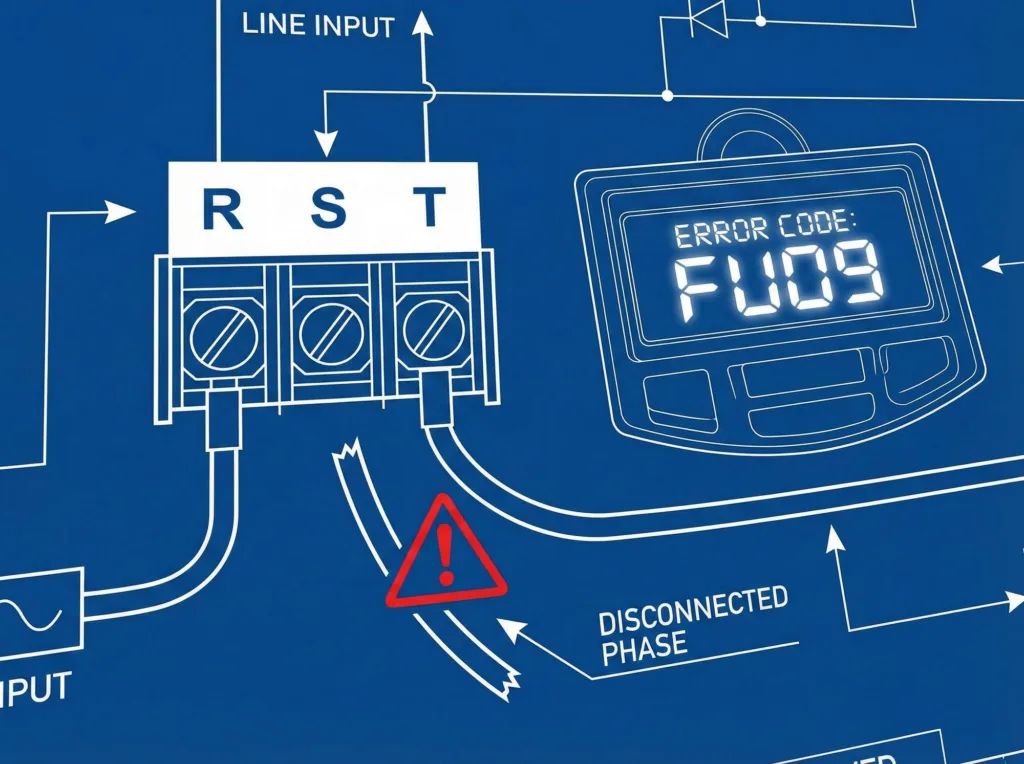

Common Symptoms of Long VFD Cable Issues

Several typical failures can be observed when VFD cable length is not properly managed:

- VFD long cable issues: Frequent overcurrent trips at startup due to high surge currents.

- Causes of VFD trip overcurrent: Excessive coupling capacitance discharges.

- Leakage current problems that trigger protective relays.

- Electromagnetic noise caused by improper filtering, especially without a dv/dt filter or sinusoidal filter.

Solutions and Best Practices for VFD Cable Length

To minimize risks, engineers should consider the following methods:

- Follow VFD cable length recommendations: Keep total wiring length within 100 meters whenever possible.

- Install VFD output reactor for long cables or a dv/dt filter to suppress harmonics and reduce reflected voltage.

- Adjust VFD carrier frequency for long cables: Lowering switching frequency can reduce spike voltages, but adjustment must be optimized based on load type and motor efficiency.

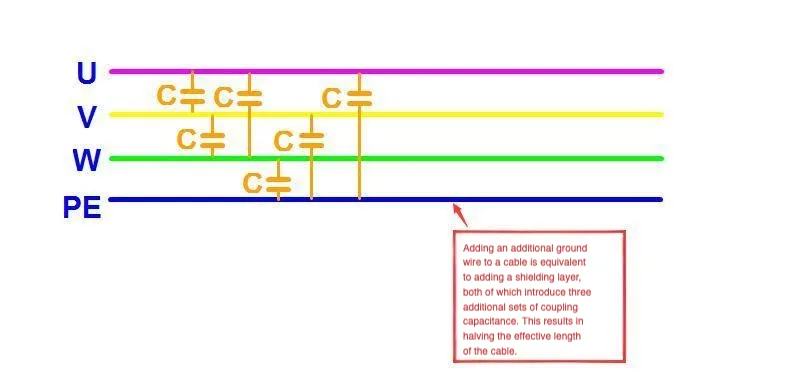

- Use shielded cable: While shielded cables reduce electromagnetic interference, note that the allowable cable length is often shorter due to additional capacitance.

- Distributed VFD control: In applications such as textile, steel rolling, or paper production lines exceeding 200 meters, multiple VFD control cabinets should be installed at different locations to balance cable length.

Conclusion

The importance of VFD cable length cannot be underestimated. Excessive cable length leads to variable frequency drive issues such as motor insulation failure, shaft voltage, inverter motor heat, and frequent VFD troubleshooting events. By applying measures like shortening the cable, installing dv/dt filters or output reactors, and carefully tuning the carrier frequency, most risks can be significantly reduced. Following VFD cable length recommendations and integrating field experience is the key to ensuring reliable and long-term motor and drive performance.