4 Causes and Fixes for VFD Cable Overheating Issues

Introduction: Why VFD Cable Overheating Matters

One of the most common variable frequency drive issues in summer is VFD cable overheating. When load increases, VFD output cables can heat up significantly, posing risks to both equipment and safety. Unlike conventional motors, VFD-driven systems require specialized analysis and solutions. In this article, we explore the causes of overheating and provide practical strategies to prevent it.

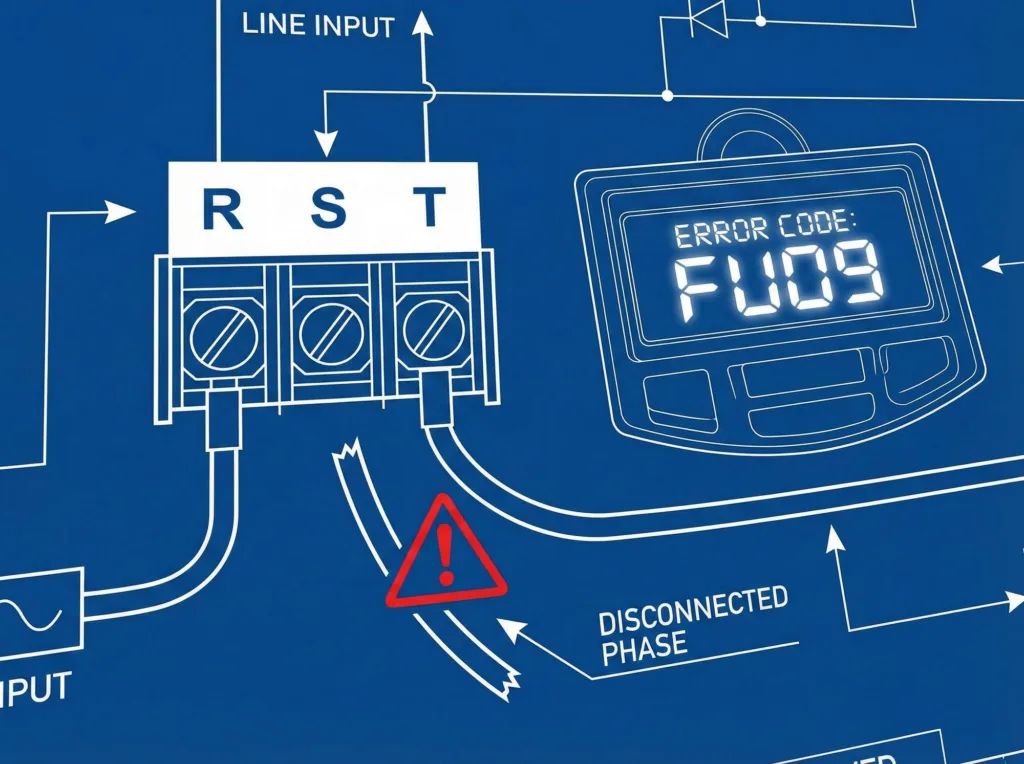

Causes of VFD Cable Overheating

The root cause of VFD cable overheating lies in waveform distortion. A VFD does not output a pure sine wave but instead produces rectangular pulses with high harmonic content.

- VFD cable harmonics increase current losses and generate excessive heat.

- Harmonic currents and surge discharges form additional thermal stress.

- This complexity makes VFD motor wiring more vulnerable compared to standard AC motors.

Understanding these effects is the first step in solving how to prevent VFD cable overheating.

Proper VFD Output Cable Sizing

Selecting cables for VFD applications is not the same as sizing cables for line-fed motors.

- VFD output cable sizing should always be one size larger than standard motor cables.

- Harmonics typically add 20–30% extra current, which can overheat cables sized for normal motors.

This adjustment reduces both cable temperature and the risk of premature insulation failure.

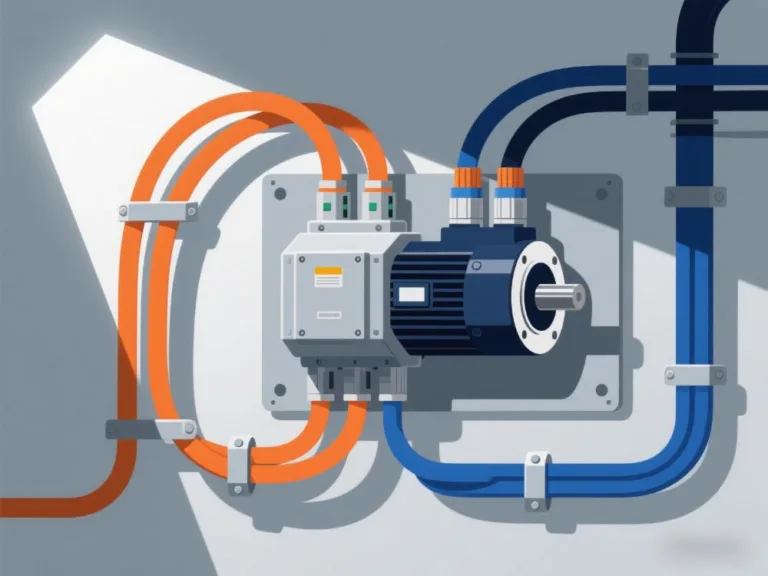

VFD Motor Cable Selection and Installation Practices

In addition to size, proper cable selection and installation play a key role:

- Avoid tightly bundling multiple VFD output cables—ensure airflow for cooling.

- Prevent using three-phase four-wire cables, which may cause zero-sequence harmonic currents and overheating of the neutral conductor.

- Use symmetrical three-core cables or evaluate shielded vs unshielded VFD cable depending on site EMC requirements.

The right VFD motor cable selection improves safety and minimizes variable frequency drive issues.

Reducing Heat Through Carrier Frequency and Reactors

Since harmonics are the main cause, reducing harmonics is the most effective solution.

1. VFD carrier frequency adjustment

- Lowering carrier frequency reduces harmonic currents and heat.

- For constant torque loads, test carefully to avoid motor vibration.

- For VFD fan and VFD pump loads, adjustments are safe but may increase noise.

2.VFD output reactor for long cables

- For cable lengths over 100m, reactors suppress harmonics and surge voltages.

- This prevents VFD long cable overheating and extends cable life.

Conclusion: A Systematic Solution to VFD Cable Overheating

To eliminate VFD cable overheating, engineers should take a systematic approach:

- Upsize cables using proper VFD output cable sizing;

- Ensure correct VFD motor cable selection instead of standard wiring;

- Improve cooling and spacing during installation;

- Apply VFD carrier frequency adjustment and VFD output reactors for long cables.

With these measures, you can reduce variable frequency drive issues and achieve stable, reliable operation.