4 Steps to Fix a VFD Overheating Fault

VFD Overheating Fault Analysis and Solutions

Hello everyone, today we are going to discuss a common but often overlooked issue — VFD overheating fault. With rising summer temperatures, overheating problems in variable frequency drives will occur more frequently. For frontline technicians or those not deeply familiar with VFD principles, encountering an “overheating” alarm can be confusing. This article provides a structured troubleshooting guide to help identify and solve the problem efficiently.

What is a VFD Overheating Fault?

A VFD overheating fault is triggered when the VFD heat sink temperature exceeds the allowable limit. This threshold is typically factory-set and cannot be modified by users. In most cases, the limit is around 60℃. If the heat sink rises above this value, the system triggers an overtemperature fault to protect the hardware.

The detection point is the heat sink — the large aluminum base at the bottom of the VFD, where rectifier and inverter modules are mounted. For smaller VFDs (≤7.5kW VFD), the IPM module (Intelligent Power Module) is commonly used, which integrates temperature detection, IGBT protection, and drive circuits internally.

Principle of Overheating Protection

The overheating protection circuit relies on a thermistor or thermal sensor. As the temperature of the heat sink rises, the resistance of the thermistor changes, converting into a voltage signal. When this voltage exceeds a preset reference, the comparison circuit reverses logic and the VFD immediately trips, displaying an inverter fault code on the panel. The primary protection target is the IGBT module, which is highly temperature-sensitive.

Fault Analysis and Troubleshooting

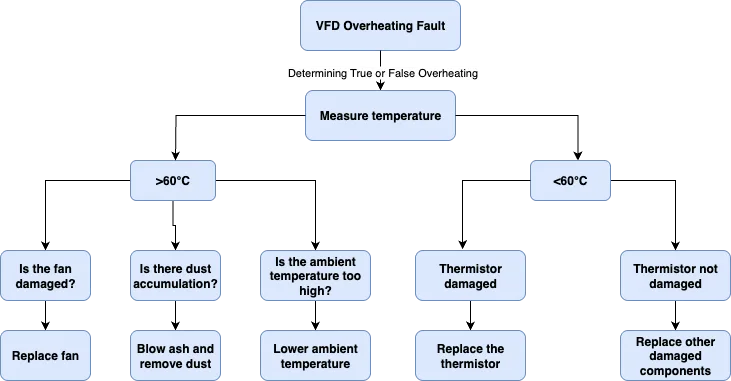

When a VFD overheating fault occurs, the first step is to determine whether it is a true overheating case or a false alarm.

True Overheating

If a thermal gun shows temperatures clearly above 60℃, it is a real overheating problem. Possible causes include:

- Cooling fan failure: Check whether the fan is stuck or damaged. If it’s not working, replace it. (VFD cooling fan not working)

- Dust accumulation: Excessive dust buildup reduces cooling efficiency. Perform VFD dust cleaning to restore proper heat dissipation.

- High ambient temperature: If the control room reaches 40℃, the remaining temperature margin is too small. Install cooling or air conditioning. (VFD ambient temperature range)

- High carrier frequency: Reduce the VFD carrier frequency to lower IGBT switching losses, which helps decrease IGBT temperature.

False Overheating

If the VFD case is not hot and the measured temperature is normal, the issue may be a false overheat trip caused by faulty detection:

- Damaged thermistor: Long-term heat stress may cause the thermistor to break. Replace with a new component.

- Faulty detection circuit: If the thermistor is intact, check the rest of the detection circuit with a multimeter and replace defective parts.

Preventive Maintenance and Recommendations

To minimize VFD overheating faults, consider these measures:

- Regularly clean dust and ensure ventilation paths are clear.

- Check cooling fans periodically to ensure proper operation.

- Improve room temperature control for high-load environments.

- Inspect thermal sensors, thermistors, and IPM modules regularly.

- Use a preventative maintenance plan with a detailed troubleshooting guide and circuit diagram.

Conclusion

The essence of a VFD overheating fault is the self-protection mechanism of the VFD against VFD motor overheating and IGBT damage. Common causes include fan failure, dust accumulation, high ambient temperature, and sensor aging. With proper fault analysis, VFD troubleshooting, and preventative maintenance, users can significantly reduce overtemperature faults and keep variable frequency drives running safely even under summer peak loads.