6 Ways to Reduce VFD Leakage Current Effectively

Case Analysis: Understanding VFD Leakage Current in Real Applications

Hello everyone, today I want to share a real on-site case that many engineers are concerned about. The issue is about significant VFD leakage current in motors, sometimes reaching several amps or even over ten amps. This raises two common questions:

- Is such motor leakage current harmful to the motor or the VFD drives?

- How should we reduce it effectively?

Case Background: High Leakage Current in a Large Motor System

Here is the specific situation:

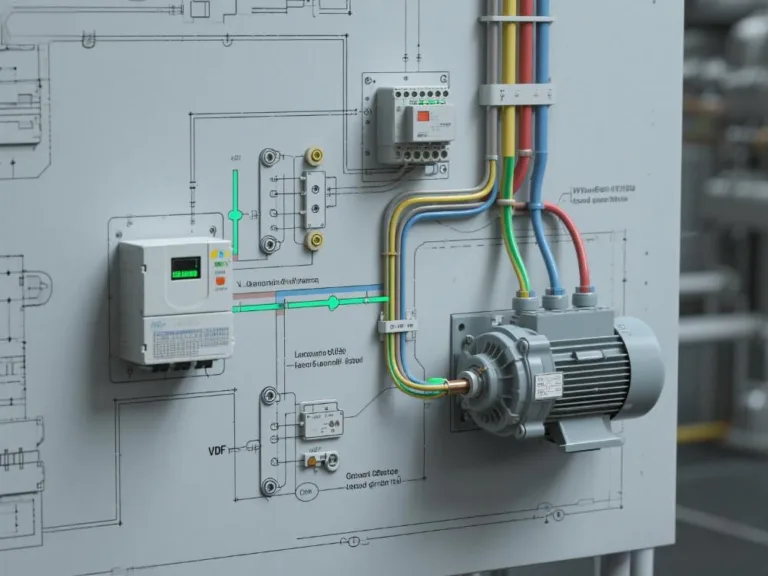

A user is running a 160 kW VFD with a 132 kW motor, using a cable length of 96 meters. The motor grounding resistance is 2 ohms, and both the VFD and motor are properly grounded. When measured with a clamp meter, the protective grounding wire showed 15A of current. The user’s concern was: “How can we eliminate this leakage current? If we continue operating like this, will it damage the motor or the VFD?”

Initial Analysis: VFD Leakage Current Is a Normal Phenomenon

First of all, this VFD leakage current is a normal phenomenon, not an unusual or dangerous fault. As long as it does not form shaft voltage or shaft current, it is not harmful to either the motor or the VFD. The main issue is psychological—once users notice 10–15A flowing on the ground line, they often feel uneasy, even though technically this does not directly endanger the equipment.

The reason is that whenever a variable frequency drive operates, the IGBT switching generates high-frequency harmonics. These harmonics travel along the motor cables, and part of the energy couples with the ground, forming leakage current. This is an inherent characteristic of VFDs and VFD motor wiring, not a malfunction.

Misuse of Residual Current Devices (RCDs) with VFDs

Many design institutes or end-users, not fully understanding VFD characteristics, install conventional ground fault protection devices (RCDs or GFCIs) on the input power side. Once installed, the large VFD ground current causes frequent VFD tripping on ground fault, leading to unnecessary downtime.

In reality, installing a normal leakage protection device on a VFD input is meaningless. Why? Because:

- The VFD is already grounded.

- The motor is grounded.

- Even the cable shields are grounded.

Adding a leakage protector only causes nuisance tripping and interrupts production. For this reason, professional design institutes typically do not recommend conventional RCDs for VFDs.

Development of VFD-Compatible Leakage Protectors

In recent years, due to user demand, some manufacturers have developed VFD compatible GFCI devices. These devices work differently: they only detect leakage current below 100 Hz, while ignoring higher-frequency leakage caused by harmonics. Since most VFD common mode current and VFD cable length leakage current are in the kHz range, these devices avoid frequent false tripping.

However, even with these special protectors, occasional tripping cannot be avoided. Moreover, the trip threshold needs to be set much higher (300–500 mA). If set to the conventional 25–30 mA, the VFD will trip immediately upon startup. This makes such protection devices less meaningful in real industrial use.

The best practice, therefore, is not to install conventional leakage protectors on VFD inputs at all.

Practical Measures to Reduce VFD Leakage Current

Although leakage current cannot be eliminated, it can be reduced through several measures:

1.Reduce carrier frequency (VFD carrier frequency reduction)

Lowering the switching frequency reduces the number of harmonic pulses generated by IGBTs, thereby lowering both harmonic current and leakage current. Care must be taken: if the motor load is rigid (gear-driven or chain-driven), lowering the carrier frequency too much may cause vibration. For VFD pumps or VFD fans, this adjustment is generally safe.

2.Shorten motor cable length

The longer the cable, the higher the capacitive coupling and leakage current. Proper VFD output cable sizing is crucial in reducing leakage.

3.Avoid shielded cables when possible

Although shielded cables help against EMI, shielded vs unshielded VFD cable design affects leakage current significantly. Shielded cables increase leakage because of higher capacitive coupling. For leakage-sensitive applications, use three-core unshielded cables.

4.Install output reactors or filters

Adding a VFD output reactor for long cables or a du/dt filter suppresses harmonics, peak voltages, and reduces leakage currents. Be careful when using LC filters: the capacitor side must connect to the motor, while the inductor side connects to the VFD. Reversing them can damage the inverter.

5.Avoid buried or steel-conduit cables

Over-ground cable trays with ventilation are preferable. Steel conduits increase parasitic capacitance and worsen VFD leakage current.

6.Use symmetric three-core motor cables

A three-core non-shielded cable reduces imbalance compared to three-phase-four-wire cables, mitigating circulating currents and leakage.

Conclusion: Leakage Current Is Inherent to VFD Systems

To summarize: VFD leakage current is an inherent byproduct of high-frequency switching and harmonics. It cannot be fully eliminated, only mitigated. As long as it does not lead to shaft current or insulation breakdown, it poses no direct harm. Installing conventional leakage protectors on VFD inputs only creates unnecessary tripping and downtime.

The correct engineering mindset is not to fear the leakage itself, but to understand its origin and manage it with proper VFD motor cable selection, harmonic suppression, and reasonable grounding practices.