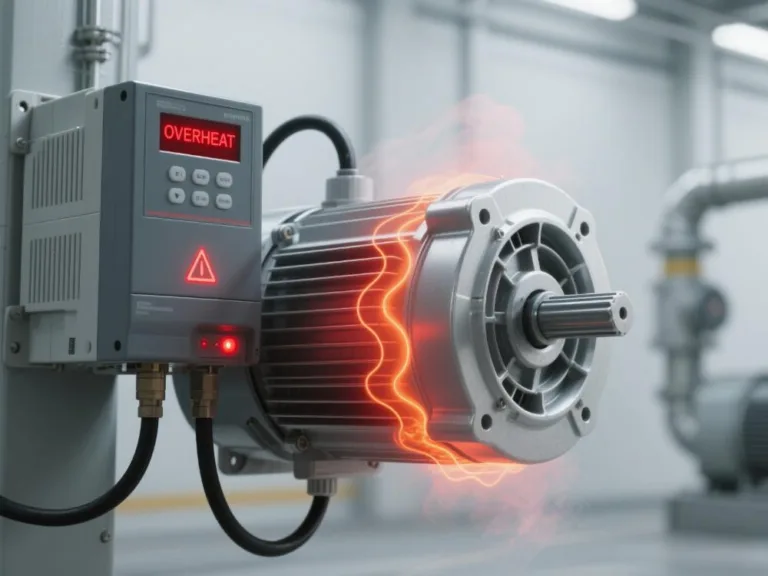

7 Causes & Fixes for VFD Motor Overheating

Introduction

When using a VFD drives, one of the most common problems faced in industrial applications is VFD motor overheating. Today, let’s analyze a real case: a 132 kW motor driven by a 160kW VFD with VF control under constant torque load. The working current is 170A, carrier frequency 2.5kHz, cable length 15m. The issue: the motor is overheating seriously—how should it be resolved?

This is not an isolated case. In fact, inverter motor heat is a widespread challenge in VFD applications. The causes are complex and often interrelated. Below, we will break down the causes of motor overheating with VFD and provide practical solutions.

Causes of VFD Motor Overheating

1. Harmonic Current

VFDs output PWM (Pulse Width Modulation) rectangular waves rather than pure sine waves. This produces harmonic currents, which flow into the stator windings and rotor bars, causing severe harmonic heating in motors.

2. High-Frequency Harmonic Voltage

High-frequency voltage components generate eddy currents in the motor core, leading to stator and rotor heating and reduced motor efficiency.

3. Low-Frequency Operation Cooling Issues

At frequencies below 20 Hz, the motor’s cooling fan runs too slowly to provide adequate airflow. This results in low frequency motor heating and rapid temperature rise.

4. Using Standard Motors as VFD Motors

Many installations use cheaper standard motors instead of inverter-duty motors. However, these motors lack optimized insulation, lamination design, and cooling capacity, which makes them vulnerable to VFD motor overheating.

5. Improper Carrier Frequency

Carrier frequency directly impacts losses:

- Too low → increased copper losses (winding overheating)

- Too high → increased iron losses (core heating) This imbalance is a typical VFD carrier frequency motor temperature issue.

6. Heavy Load at Low Frequency

High load currents combined with insufficient fan cooling significantly raise motor temperature.

7. Long Motor Cable

When cable length exceeds 50m, voltage reflection and spikes occur at the motor terminals, intensifying long VFD cable motor overheating and insulation stress.

How to Fix VFD Motor Overheating

1. Optimize Carrier Frequency

Adjust carrier frequency step by step (e.g., from 2kHz to 6kHz) while measuring temperature. This VFD troubleshooting approach helps find the optimal operating point.

2. Forced Cooling for VFD Driven Motors

If the motor runs frequently below 20Hz, install an independent cooling fan. This ensures proper motor temperature control.

3. Use Output Reactors or Filters

Adding a VFD output reactor for motor heat, dv/dt filter, or sinusoidal filter reduces harmonics and voltage spikes, protecting motor winding insulation and lowering heat.

4. Shorten Cable Length

Keep motor cables under 50m. For longer runs, use inverter-rated cables or install filters to minimize variable frequency drive issues.

5. Use Symmetrical Shielded Cables

Three-core shielded VFD cables can reduce common mode current, lowering extra heating effects.

6. Choose Larger Motor Capacity

Using a motor one size larger reduces thermal stress, improving long-term motor efficiency and reliability.

7. Ensure Proper Grounding

Establishing a solid equipotential ground minimizes VFD leakage currents, lowering extra heating risks.

8. Avoid Long-Term Low-Frequency Operation

If low-speed operation is necessary, combine with forced cooling and continuous monitoring.

Conclusion

VFD motor overheating is a multifactorial issue caused by harmonics, cooling limitations, cable effects, and carrier frequency settings. No single solution is enough; instead, multiple how to fix VFD motor overheating methods should be combined.

Through optimized carrier frequency, proper cooling, filtered outputs, shorter cable runs, and correct motor selection, overheating risks can be minimized. This not only improves variable frequency drive performance but also extends motor life and reliability in demanding applications.