Air Compressor VFD PM Motor Fault: 4 Causes, 3 Steps to Fix

Hello everyone, today I’ll share a field failure case involving troubleshooting abnormal startup of an Air Compressor VFD (VFD Drives) with a Permanent Magnet (PM) motor. The issue is described as follows:

The air compressor employs vector control via the VFD. After the PM motor starts and the frequency reaches 5 Hz, the VFD automatically restarts. Upon restarting, it again stops at 5 Hz. The display shows “Host Starting,” with the frequency flashing between 60–200 Hz. A distinct “clicking” sound from relays engaging is audible inside the enclosure, and the output remains no-load.

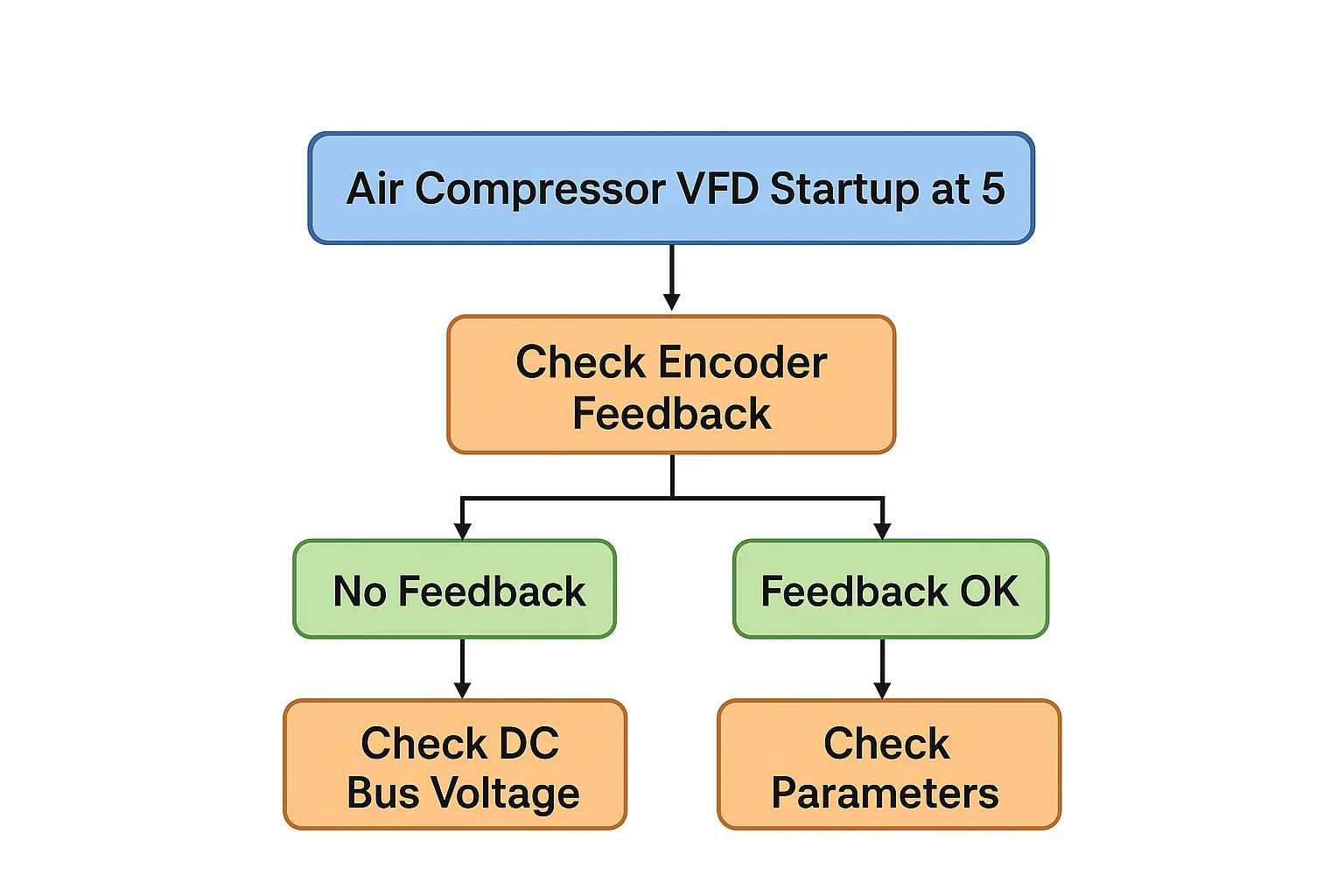

Below is an analysis of potential causes ranked from most to least likely, along with key troubleshooting points (VFD troubleshooting approach).

Encoder Feedback Error in Air Compressor VFD

Permanent magnet motors rely on encoder feedback for positioning and speed measurement. Many vector control drives begin detecting feedback signals when switching to closed-loop control at 0–5 Hz:

- If no encoder signal is detected at 5 Hz, the Air Compressor VFD triggers feedback error protection and enters an automatic restart cycle;

- Recommended troubleshooting sequence:

- Replace or temporarily connect a known-good encoder;

- Inspect encoder power supply, wiring, shielding, and grounding;

- Manually rotate the encoder shaft in the control room and observe if the control panel feedback changes;

- If no feedback is present in the control room, the VFD encoder input port or optocoupler may be damaged.

Critical Note: Static electricity and poor shield grounding can easily burn out encoder ports, requiring extra caution during winter.

Motor or Cable Faults

- Phase loss, phase-to-phase short circuits, or poor terminal contact in motor windings can trigger overcurrent protection during startup;

- Cable crushing, ground shorts, or poor shield grounding may also cause startup abnormalities;

- Use a megohmmeter to test insulation resistance and inspect terminal boxes for moisture or carbonization.

Issues with the Air Compressor VFD Itself

A “clicking” sound is often related to the precharge circuit or current limiting unit operation:

- Aging DC bus capacitors can cause severe voltage fluctuations during startup;

- Aging voltage detection circuits or mainboards may cause relays to repeatedly engage;

- Recommendations:

- Check DC bus capacitor capacity and ESR;

- Observe bus voltage variation waveforms;

- Verify proper operation of precharge relay contacts and current limiting unit.

These issues typically represent aging failures after prolonged operation of the Air Compressor VFD.

Incorrect Air Compressor VFD Parameter Settings

Such faults are often related to PM motor control:

- If a permanent magnet synchronous motor is mistakenly configured as an asynchronous motor, or if incorrect motor nameplate parameters are entered, the VFD cannot complete vector self-test;

- Excessively short acceleration time or unreasonable starting torque settings may cause overcurrent or stall during startup;

- It is recommended to re-execute autotuning (PM motor), verifying motor parameters, torque curve, and vector control mode;

- For systems with absolute or incremental encoders, calibrate the encoder direction and zero point.

Troubleshooting Approach (VFD Troubleshooting Checklist)

To efficiently pinpoint issues, follow this elimination method:

- 1.Disconnect the original motor and connect a known-good test motor:

- If operation is normal, the problem lies with the original motor or its cable/encoder;

- If still abnormal, the issue may lie with the VFD or control circuit.

- 2.If the VFD passes self-test, progressively expand the troubleshooting scope (cable → encoder → motor → VFD port).

- 3.Use an oscilloscope to record key points (encoder signals, bus voltage, I/O trigger status) to help diagnose transient behavior.

Core Logic for Air Compressor VFD Fault Diagnosis

Overall, when an Air Compressor VFD automatically restarts near 5 Hz, the most probable root cause is a VFD encoder feedback error.

Additionally, be vigilant for precharge circuit issues caused by aging DC bus capacitors and protective actions triggered by incorrect PM motor parameter settings.

Key on-site diagnostic principles:

- Rapidly distinguish between “internal VFD issues” and “external factors”;

- Effectively utilize elimination methods and oscilloscope tools;

- Systematically validate the encoder, main board, and motor following manufacturer-recommended procedures.

Mastering these core principles significantly enhances field engineers’ efficiency in analyzing and maintaining Air Compressor VFD systems.