3 Real Causes of VFD Overvoltage Fault: Static, Aging & Grid

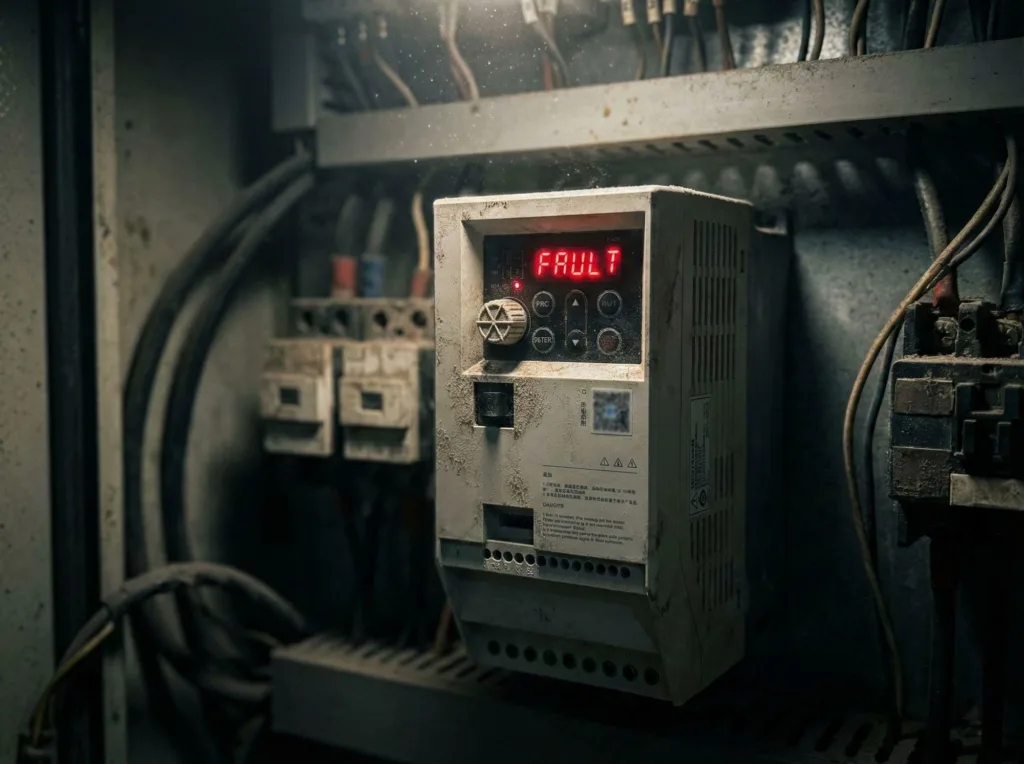

Today, we’re reviewing a fault that trips up even seasoned veterans: the VFD clearly has normal voltage, yet it repeatedly reports a VFD Overvoltage Fault.

I’m Jin Gong from Oulu Electric. On-site, I’ve seen too many people replace the mainboard or even the entire unit due to this false alarm, only to find the problem persists. This is actually a classic case of “false overvoltage.”

The root cause of VFD Overvoltage Faults often lies not in the voltage itself, but in “interference” and “aging.” Drawing from years of hands-on experience, I’ll break down the three main culprits behind this issue.

The Invisible Killer: Static Dust Accumulation

This is the most easily overlooked yet most destructive cause.

Dust accumulation on control circuit boards is far more than mere grime. During dry seasons (like winter), this dust becomes an excellent carrier for static electricity, accumulating charges reaching thousands or even tens of thousands of volts.

When this static discharges (ESD), it generates intense electromagnetic interference.

- Minor consequences: Interference with voltage detection signals may cause the CPU to misjudge, directly triggering a VFD Overvoltage Fault.

- Severe consequences: It can directly damage precision chips, causing permanent failure.

Solution: Don’t cut corners—thoroughly remove dust. Use dry compressed air to blow the inverter’s interior completely clean. Once dust is eliminated, static electricity loses its breeding ground. This is precisely why we repeatedly emphasize in the Oulu VFD User Manual’s maintenance section: Maintaining cleanliness is the most cost-effective method to eliminate VFD Overvoltage Faults.

The Liar: Aging Voltage Detection Circuit

If the dust is blown away and the VFD Overvoltage Fault persists, suspect that the inverter may be “lying.”

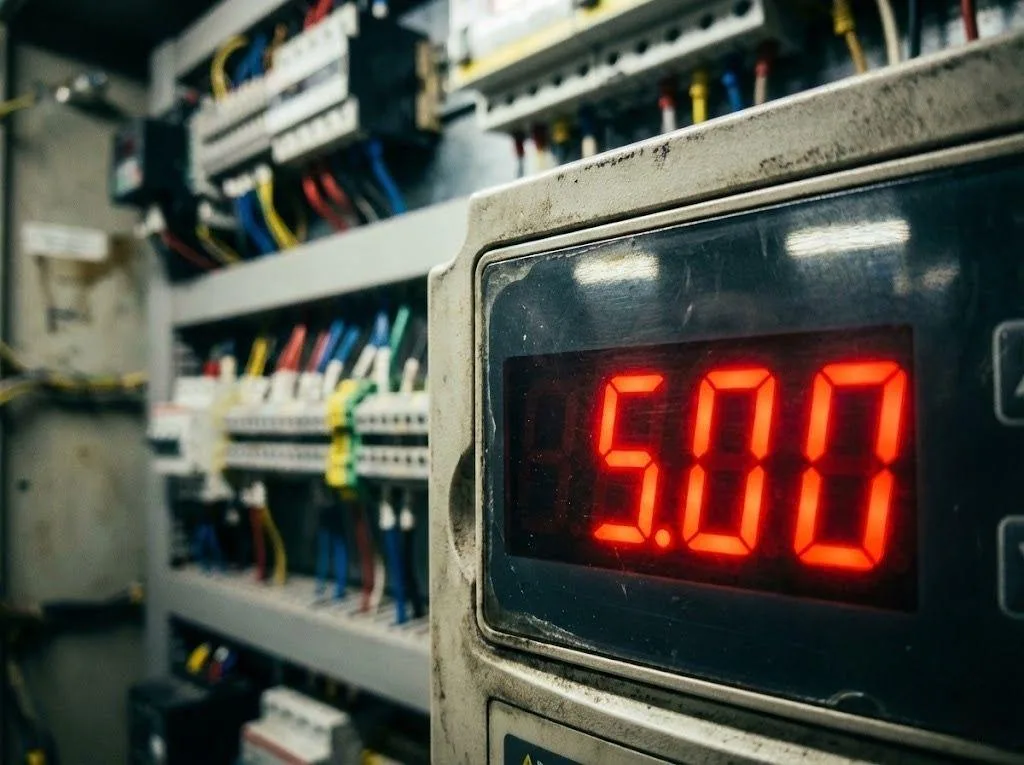

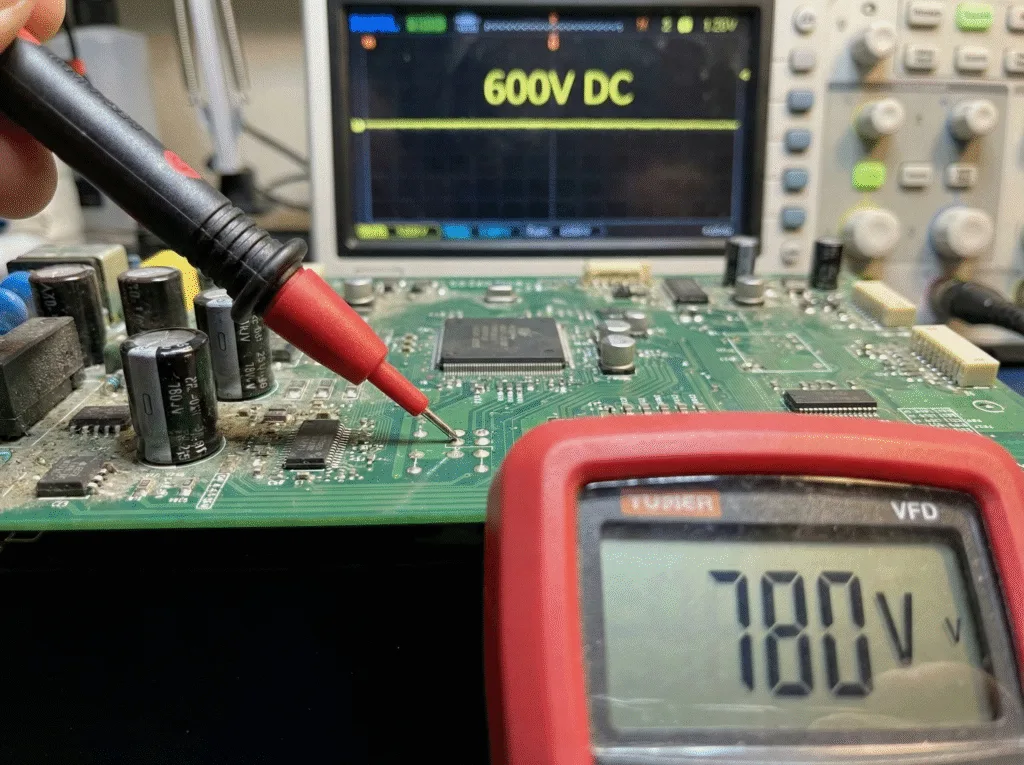

This is a classic case of “false detection.” Under normal conditions, the DC bus voltage may only be 600V (within the normal range). However, due to aging components like resistors and operational amplifiers in the voltage detection circuit, their characteristics drift. Consequently, the data fed back to the CPU becomes 750V or even 780V. The CPU mistakenly believes a true overvoltage has occurred and immediately triggers shutdown protection.

Rule of thumb:

- Timeframe: For most reputable brands, this aging drift typically occurs after 6-8 years of operation.

- Environmental factors: If your site experiences prolonged high temperatures and humidity, this timeframe may shorten to 3-4 years.

Reference the Oulu EV510A design, which incorporates high-precision detection components and thickened triple-proof coating to delay this aging process effectively. However, if the equipment is already “overdue for replacement,” replacing the detection board or mainboard is the only solution to resolve the VFD Overvoltage Fault.

The Unstable Source: Generator Power Supply

The final scenario involves the root cause—the power grid itself.

If you’re relying on generator power or experiencing extremely unstable grid conditions, VFD Overvoltage Faults will occur frequently. Unstable voltage regulation from generators can generate transient high-voltage surges.

A highly effective workaround: If you don’t have an oscilloscope, connect an incandescent light bulb to the circuit.

- If the bulb glows white and becomes uncomfortably bright, it indicates the voltage has surged above 260V.

- If the bulb flickers on and off, it indicates severe voltage fluctuations.

This physical overvoltage is a genuine VFD Overvoltage Fault. While rare with utility power (mains supply), it’s crucial to inspect the generator’s AVR (Automatic Voltage Regulator) if using private power generation.

Conclusion

When encountering a VFD overvoltage fault, don’t immediately suspect the motherboard failure.

Start with the most basic maintenance—cleaning dust to eliminate electrostatic interference. Then inspect the generator waveform to verify input power quality. Only then should you consider hardware aging causing false detection.

Take the Oulu EV510A we referenced: although its circuit board features a thickened triple-proof coating that effectively resists static and moisture, regular VFD maintenance remains paramount in harsh environments. As engineers, we must rely on data, not guesswork, to accurately resolve VFD Overvoltage Faults.