EV200-0004G-S2: Compact Single Phase VFD | 0.4kW, 220V

Why Choose This 0.4 kW (0.5HP) 220V Single Phase VFD?

Choosing the right drive is crucial for performance and reliability. This specific 0.4 kW (0.5HP) VFD is the ultimate space-saver and the ideal choice for straightforward applications.

Designed for Tight Spaces: Its key feature is the ultra-compact narrow body design, which is 45% smaller than previous models. It also supports side-by-side installation, making it perfect for crowded control cabinets where space is a premium.

Simple and Efficient: While the EV510A series offers complex, high-count I/O, the EV200 is designed for simple speed regulation. Its streamlined 4 DI / 1 AI / 1 Relay setup provides all the necessary control for small automated machinery without unnecessary complexity or cost.

Reliable Vector Performance: Despite its small size, it delivers true vector control performance, providing excellent low-speed high-torque (150% at 0.5Hz) for reliable startups, far surpassing simple V/F control.

No Braking Unit: This model does not include a built-in braking unit, as it is part of the 0.75-2.2kW range, which is designed without them, making it a cost-effective choice for applications that do not require rapid deceleration.

Campos de aplicación típicos

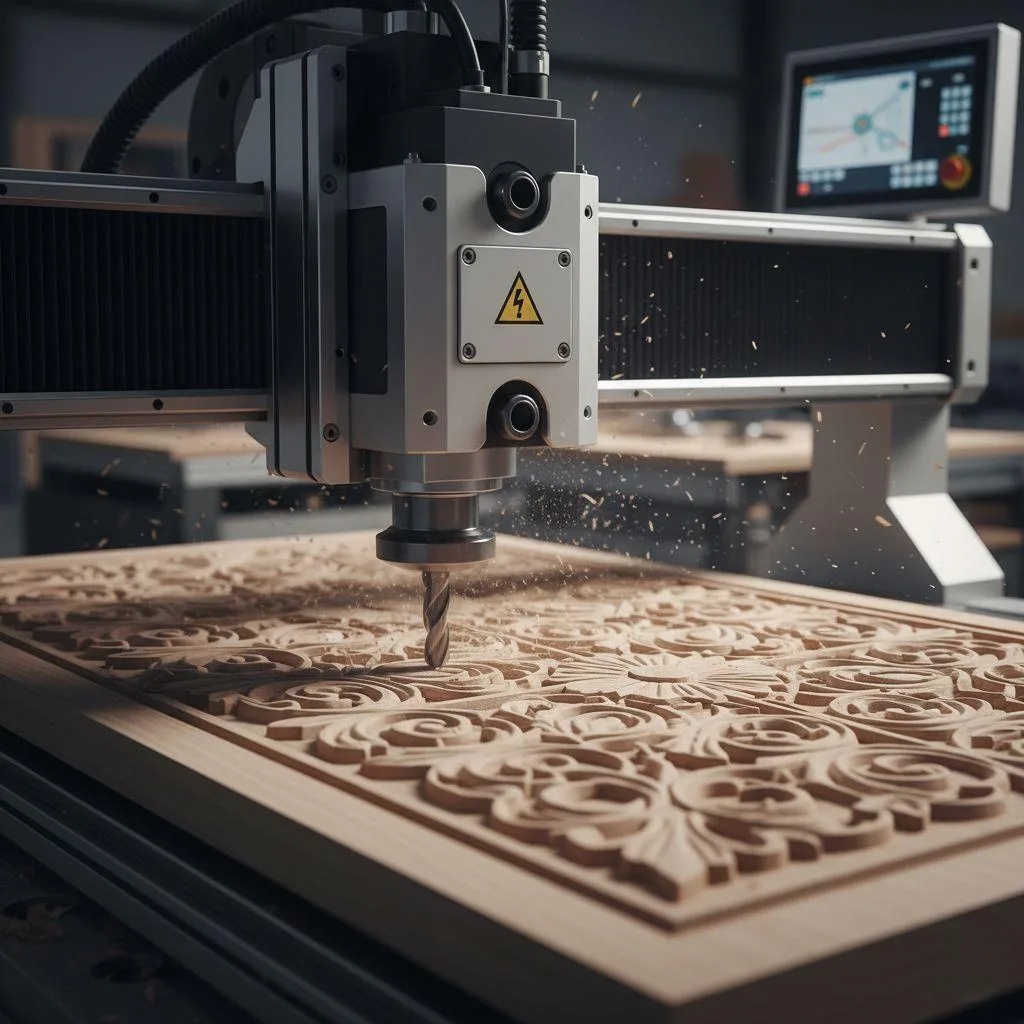

Woodworking Machinery

A perfect compact VFD for wood carving machines (engraving machines) and small spindles.

Glass & Ceramic

Provides precision speed control for glass edging machines and small grinders.

Textile Industry

Simple speed control for small textile machines and winders.

Características de control

Modo de control | sin PG Vector(SVC), control V/F |

|---|---|

Frecuencia más alta | Control vectorial: 0~500Hz; control V/F: 0~500Hz |

Par de arranque | Tipo G: 0,5Hz/150% (SVC) |

Velocidad | 1:100 (SVC) |

Precisión del control de velocidad | ±0,5% (SVC) |

Capacidad de sobrecarga | Tipo G: 150% corriente nominal 60s; 180% corriente nominal 3s |

Especificaciones de E/S

Entrada digital | 4 terminales de entrada digital |

|---|---|

Entrada analógica | 1 terminal de entrada analógica |

Salida de relé | 1 terminal de salida de relé |

Comunicación | Soporta Modbus, RS85 (Supuesto RS485), CANopen, CANlink |

Entorno operativo

Lugar de instalación | En interiores, sin luz solar directa, sin polvo, gases corrosivos, etc. |

|---|---|

Altitud | Por debajo de 1000 metros |

Temperatura ambiente | De -10°C a +40°C (reducción necesaria para 40~50°C) |

Humedad | <95%RH, sin condensación |

Dimensiones estructurales

Dimensiones (An x Pr x Al) | 73 x 112,6 x 143 mm |

|---|---|

Tamaño de la instalación (A x B) | 60 x 129 mm |

Agujero de instalación | Ф4.4 |

Garantía de calidad

Este producto ha sido desarrollado y fabricado por Nanjing Oulu Electric Corp. Como empresa nacional de alta tecnología centrada en la automatización industrial y las nuevas energías, contamos con un experimentado equipo de I+D e instalaciones de producción avanzadas, dedicados a ofrecer productos y soluciones fiables y de alta calidad a clientes de todo el mundo.

Preguntas más frecuentes (FAQ)

1. ¿Cuál es la diferencia entre el control V/F y el control vectorial sin sensores (SVC)?

V/F control is a basic method for motor speed regulation. Sensorless Vector Control (SVC) is more advanced, providing precise speed and torque control. The EV200 uses SVC to deliver high starting torque (150% at 0.5Hz), which is much better for starting loads than basic V/F.

2. Does the EV200-0004G-S2 have a built-in braking unit?

No. The EV200 series states that models from 0.75kW to 2.2kW do not have a built-in braking unit, and this 0.4kW model follows that design. An external braking resistor would be required for applications needing fast deceleration.

3. What is the key difference between the EV200 and EV510A series?

The EV200 is designed for simple speed regulation and ultra-compact size, featuring a narrow body that is 45% smaller and allows side-by-side installation. Its I/O is simplified (4 DI, 1 AI, 1 Relay). The EV510A series is a higher-performance drive with a much larger, more flexible I/O (7 DI, 2 AI, 2 AO, 2 Relay) for more complex automation tasks.

4. Can this VFD be installed in a small cabinet with other drives?

Yes. The EV200 features independent air ducts for efficient cooling and is specifically designed to be installed side-by-side with other units, making it ideal for saving space in power distribution cabinets.

Guía de inicio rápido (How-To)

Advertencia: The following steps are a basic guide only. All electrical work must be performed by qualified professional personnel. Before any wiring, ensure the main power is completely disconnected and wait at least 10 minutes for the internal capacitors of the VFD to discharge fully.

Paso 1: Instalación

Mount the inverter vertically on a sturdy, non-flammable surface, such as a metal mounting plate. Ensure there is sufficient clearance for heat dissipation. Side-by-side installation is permitted.

Paso 2: Cableado del circuito principal

Conecte el monofásico 220V Líneas de alimentación de CA a los terminales de entrada del inversor

R/L1yS/L2.Conecte los tres cables del motor asíncrono trifásico a los bornes de salida del variador.

U,V, yW.Conecte firmemente el cable de tierra al inversor.

PE(tierra de protección).

Paso 3: Cableado del circuito de control (para arranque/parada básicos)

Conecte un extremo de un interruptor externo (o botón) al terminal de entrada digital

S1.Connect the other end of the switch to the

COMterminal.Establecer parámetro

P0-02(Selección de la fuente de comandos) a “1” (Canal de comandos del terminal).Establecer parámetro

P4-00(Selección de función S1) a “1” (Marcha adelante).

Paso 4: Ajuste de los parámetros del motor y autoajuste

En el primer encendido, introduzca con precisión los siguientes parámetros de la placa de características de su motor:

P1-01: Motor Rated Power (set to 0.4kW)P1-02: Tensión nominal del motor (ajustada a 220V)P1-03: Motor Rated Current (e.g., 2.3A)P1-04: Frecuencia nominal del motorP1-05: Velocidad nominal del motor

Para un rendimiento óptimo del control vectorial, realice un autoajuste del motor. Ajuste el parámetro

P1-37(Motor auto-tuning) to “2” (dynamic auto-tuning) or “3” (static auto-tuning) and start the inverter.

Paso 5: Prueba de funcionamiento

Después de confirmar que todo el cableado y los ajustes de los parámetros son correctos, conecte la alimentación principal. Cierre el interruptor externo conectado entre S1 y COM. El motor debe empezar a girar en dirección de avance. Abra el interruptor y el motor se detendrá de acuerdo con el tiempo de deceleración establecido.

Principales características y ventajas

Ultra-Compact Narrow Body: Features a new narrow body design and compact structure. Compared to older products, the installation size is reduced by 30% and the volume by 45%, saving installation space and reducing distribution costs.

Space-Saving Installation: The design features independent air ducts for efficient, straight-through heat dissipation, which allows for side-by-side installation to maximize use of cabinet space.

High Starting Torque: This AC motor drive is capable of 0.5Hz starting torque at 150% under Sensorless Vector Control (SVC), providing excellent low-speed performance for general-purpose loads.

Robust Overload Capacity: As a G-type drive, it handles 150% of its rated current for 60 seconds and 180% for 3 seconds, ensuring stability during load changes.

Simplified I/O: Designed for simple speed regulation, this model features a streamlined I/O configuration of 4 digital input terminals, 1 analog input, and 1 relay output.

Smart Integrated Functions: Includes a built-in PID controller for process control, a Simple PLC for multi-stage speed running, and Auto-adjust voltage (AVR) to keep output voltage steady when the grid voltage changes.

Archivo | Talla | Acción |

|---|---|---|

Guía de selección de VFD.pdf | 4,2 MB | |

VFD EV200 Manual de Usuario.pdf | 1,4 MB |