How to Diagnose Motor Overheat in a 90kW VFD Driving Two 30kW Motors

In industrial applications such as overhead cranes, it’s common to use a 90kW variable frequency drive (VFD Drives) to power two 30kW travel motors. However, if one motor experiences overheating—a classic motor overheat condition—while the other remains cool, something is seriously wrong.

This guide outlines four major reasons for motor overheat in dual VFD motor systems, including mechanical resistance, internal motor faults, long cable effects, and carrier frequency-induced harmonics.

What Causes Motor Overheat in a VFD-Driven Dual Motor System?

Let’s explore the most likely causes of motor overheat when both motors are powered by the same inverter:

1. Mechanical Load Imbalance

One of the most overlooked causes of motor overheat is uneven mechanical loading. In crane systems, factors such as worn bearings, insufficient lubrication, or gearbox misalignment can place higher resistance on one motor.

- This increases torque demand

- Which raises current draw

- Ultimately causing internal heat buildup

Fix: Conduct a mechanical audit—inspect the reducer, gears, shafts, and load symmetry.

2.Internal Motor Faults

Sometimes the problem lies inside the motor itself. A motor overheat issue may stem from:

- Partial short circuits in the winding

- Rotor bar cracks

- Insulation breakdown

These faults are often invisible to a multimeter test, especially when cold.

Diagnostic Tip: Swap the two motors. If the overheating follows the motor, it confirms the issue is internal.

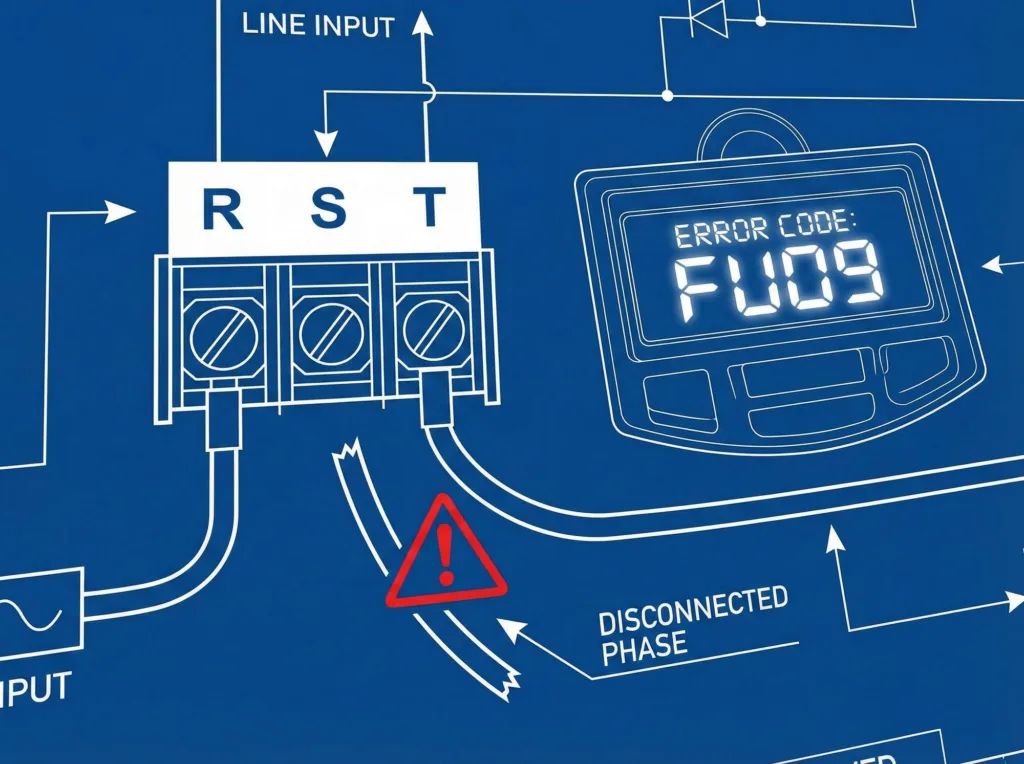

3.Long Cable from VFD to Motor

If the cable between the VFD and the overheating motor exceeds 50 meters, motor overheat may result from reflected wave phenomena and voltage spikes. These are caused by:

- Long cable lengths increasing capacitive effects

- VFD switching (typically IGBT-based) generating high-frequency harmonics

- Harmonics accumulating and creating voltage peaks inside motor windings

Fix: Add an output reactor or sinusoidal filter to suppress harmonics. It protects the motor and reduces heat.

4.Carrier Frequency Too High

High carrier frequency settings in the VFD can also contribute to motor overheat—especially when paired with long cables or sensitive loads.

While reducing the carrier frequency helps minimize harmonic generation, doing so might lead to mechanical vibrations or motor torque pulsations, especially under heavy load.

Adjustment Strategy: Lower the carrier frequency gradually and monitor for vibration. If instability occurs, revert and instead install a filter.

Final Thoughts on VFD Dual Motor Overheat Problems

In a dual-motor setup, a VFD overheating one motor isn’t just inconvenient—it signals a serious motor overheat problem that can lead to insulation failure, torque imbalance, or even equipment shutdown. Focus on mechanical balance, cabling practices, and VFD tuning to prevent long-term damage.