Overcurrent Fault and Motor Vibration with No Visible Faults

Introduction – Diagnosing a Real-World VFD Overcurrent Fault Case with Motor Vibration

Hello everyone. Today, I’d like to share a real-world VFD drives system troubleshooting case that many engineers might encounter onsite.

Here’s what happened:

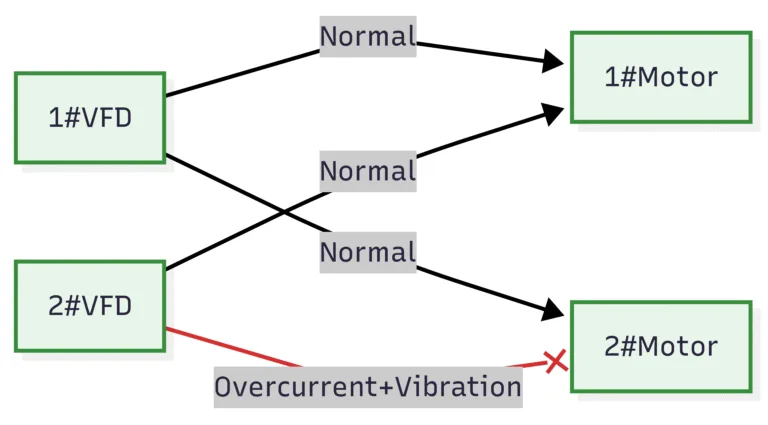

A VFD drives system operated perfectly when connected to Motor #1, but when connected to Motor #2—which is the exact same model—it caused motor vibration and overcurrent alarms.

The customer performed a full cross-test and got these results:

- VFD #1 + Motor #1: Normal

- VFD #1 + Motor #2: Normal

- VFD #2 + Motor #1: Normal

- VFD #2 + Motor #2: Vibration + Overcurrent Alarm

The client was puzzled: “The devices and parameters are identical—so where’s the problem?”

Why Traditional Diagnosis Fails for VFD Overcurrent Fault Troubleshooting

Visual Symptoms Can Be Misleading in Motor Vibration Faults

Here lies the core issue—not in the hardware, but in mindset.

The customer was still applying traditional line-frequency logic when diagnosing the problem. In line-power systems, it’s common practice to swap motors or controllers to identify faults through comparison. That works for line-voltage systems—but not for VFD drive systems.

Why?

Because what looks the same to a human is not the same to the VFD.

Root Cause – No Auto-Tuning Leads to VFD Overcurrent Faults

How VFDs Learn Each Motor’s Electrical Signature

In proper commissioning procedures, before a VFD drive system drives any motor, it must run a static auto-tuning (also called motor identification) process. This teaches the VFD the exact electrical characteristics of that motor.

During self-learning, the VFD collects parameters like:

- Stator resistance and inductance

- Rotor resistance and inductance

- Leakage flux and magnetization curve

- Magnetic saturation behavior

- IGBT switching characteristics compensation

- Rotor EMF and flux dynamics

These parameters are critical for the VFD to deliver:

- High-precision speed control

- High torque output

- Smooth dynamic response

- Magnetic flux compensation and motor model tracking

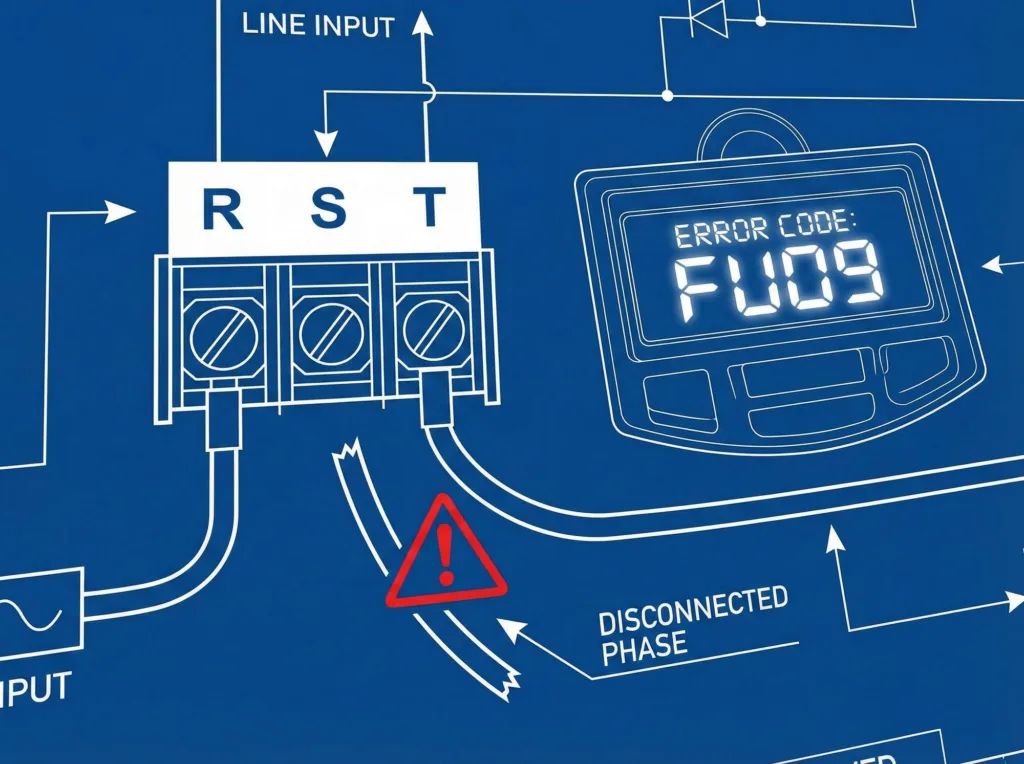

What Happens When You Skip Self-Learning in VFD Commissioning

If this step is skipped, the VFD is essentially trying to control a motor it doesn’t “know”. The result? Inaccurate control, erratic torque behavior, and issues like motor vibration and VFD overcurrent fault.

We call this a motor model mismatch—and it’s one of the most common hidden problems.

Common Scenarios Behind Sudden VFD Overcurrent Fault Alarms

Large Motor Startups and Untuned Motors

To be clear—not every system will fail if auto-tuning isn’t done.

However, based on my two decades of experience, almost every case involving:

- VFD startup vibration at power-on

- Sudden overcurrent alarms

- VFD torque ripple during acceleration or deceleration

…can be traced back to missing or incorrect motor identification.

It tends to happen more in these scenarios:

- Large motor commissioning after installation

- Motor replaced without new auto-tuning

- Systems with high dynamic demands (e.g., tension control, winding)

- One motor driven by multiple VFDs in cross-use setups

Multi-VFD Systems Sharing the Same Motor

Especially in systems where a single motor is paired with multiple VFDs at different times or via load-sharing setups, failing to auto-tune each VFD with the motor’s signature can lead to control conflicts and mismatched flux profiles.

The Correct Way to Prevent Motor Vibration and VFD Overcurrent Faults

Proper Steps for Static Auto-Tuning in VFD Setup

To fix and prevent this issue, follow this recommended sequence:

- Reset the VFD to factory settings

- Enter basic nameplate parameters from the motor

- Perform static auto-tuning / motor identification

- Store the learned parameters, and allow the VFD drive system to control using the updated motor model

In most cases, this will completely eliminate motor vibration and VFD overcurrent fault, and significantly improve motor smoothness and responsiveness.

Conclusion – Auto-Tuning Is the Key to Avoiding VFD Overcurrent Faults

For experienced VFD engineers, this is basic practice. But for technicians who come from a line-power background, or for junior engineers new to VFD drive systems, this may not be obvious.

Here’s the golden rule:

Never judge a motor by its nameplate alone. Every motor has a unique electrical signature.

Just like no two leaves in the world are identical, no two motors—even of the same model—are 100% alike in flux curves, inductance, resistance, or dynamic behavior.

And that’s exactly why VFDs rely on motor-specific modeling to function properly.

Final Takeaway

The conclusion to this case is simple and clear:

Auto-tuning was not performed.

When installing or commissioning a motor—even if it appears identical to another—always perform motor identification. This one step can save you hours of downtime, misdiagnosis, and recurring faults.

Add it to your VFD commissioning checklist—you’ll thank yourself later.