EV200-0004G-S2: Compact Single Phase VFD | 0.4kW, 220V

Why Choose This 0.4 kW (0.5HP) 220V Single Phase VFD?

Choosing the right drive is crucial for performance and reliability. This specific 0.4 kW (0.5HP) VFD is the ultimate space-saver and the ideal choice for straightforward applications.

Designed for Tight Spaces: Its key feature is the ultra-compact narrow body design, which is 45% smaller than previous models. It also supports side-by-side installation, making it perfect for crowded control cabinets where space is a premium.

Simple and Efficient: While the EV510A series offers complex, high-count I/O, the EV200 is designed for simple speed regulation. Its streamlined 4 DI / 1 AI / 1 Relay setup provides all the necessary control for small automated machinery without unnecessary complexity or cost.

Reliable Vector Performance: Despite its small size, it delivers true vector control performance, providing excellent low-speed high-torque (150% at 0.5Hz) for reliable startups, far surpassing simple V/F control.

No Braking Unit: This model does not include a built-in braking unit, as it is part of the 0.75-2.2kW range, which is designed without them, making it a cost-effective choice for applications that do not require rapid deceleration.

Typical Application Fields

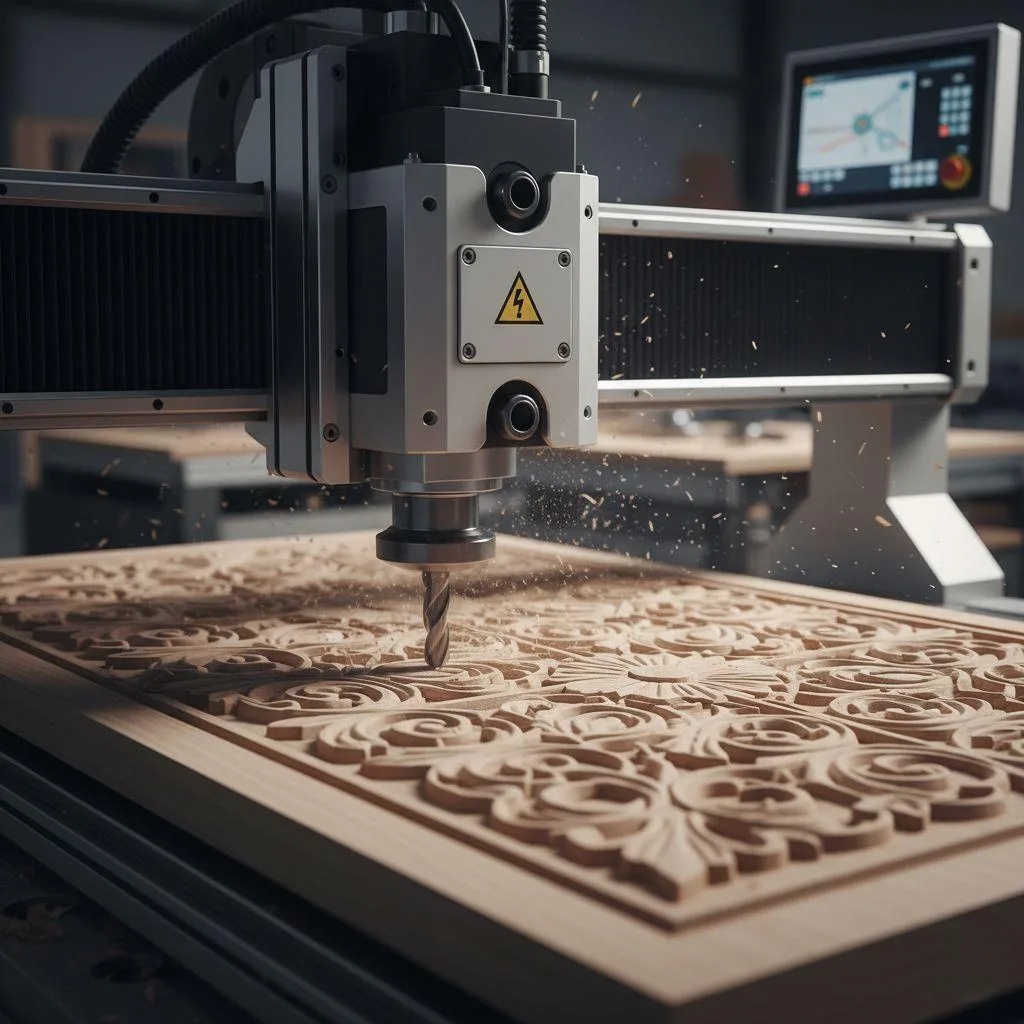

Woodworking Machinery

A perfect compact VFD for wood carving machines (engraving machines) and small spindles.

Glass & Ceramic

Provides precision speed control for glass edging machines and small grinders.

Textile Industry

Simple speed control for small textile machines and winders.

Control Characteristics

Control Mode | without PG Vector(SVC), V/F control |

|---|---|

Highest Frequency | Vector control: 0~500Hz; V/F control: 0~500Hz |

Start Torque | G type: 0.5Hz/150% (SVC) |

Speed Range | 1:100 (SVC) |

Speed Control Accuracy | ±0.5% (SVC) |

Overload Capacity | G type: 150% rated current 60s; 180% rated current 3s |

I/O Specifications

Digital Input | 4 digital input terminals |

|---|---|

Analog Input | 1 analog input terminal |

Relay Output | 1 relay output terminal |

Communication | Supports Modbus, RS85 (Assumed RS485), CANopen, CANlink |

Operating Environment

Installation Site | Indoors, no direct sunlight, no dust, corrosive gases, etc. |

|---|---|

Altitude | Below 1000 meters |

Ambient Temperature | -10°C to +40°C (derating required for 40~50°C) |

Humidity | <95%RH, no condensation |

Structural Dimensions

Dimensions (W x D x H) | 73 x 112.6 x 143 mm |

|---|---|

Installation Size (A x B) | 60 x 129 mm |

Installation Hole | Ф4.4 |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

1. What is the difference between V/F control and Sensorless Vector Control (SVC)?

V/F control is a basic method for motor speed regulation. Sensorless Vector Control (SVC) is more advanced, providing precise speed and torque control. The EV200 uses SVC to deliver high starting torque (150% at 0.5Hz), which is much better for starting loads than basic V/F.

2. Does the EV200-0004G-S2 have a built-in braking unit?

No. The EV200 series states that models from 0.75kW to 2.2kW do not have a built-in braking unit, and this 0.4kW model follows that design. An external braking resistor would be required for applications needing fast deceleration.

3. What is the key difference between the EV200 and EV510A series?

The EV200 is designed for simple speed regulation and ultra-compact size, featuring a narrow body that is 45% smaller and allows side-by-side installation. Its I/O is simplified (4 DI, 1 AI, 1 Relay). The EV510A series is a higher-performance drive with a much larger, more flexible I/O (7 DI, 2 AI, 2 AO, 2 Relay) for more complex automation tasks.

4. Can this VFD be installed in a small cabinet with other drives?

Yes. The EV200 features independent air ducts for efficient cooling and is specifically designed to be installed side-by-side with other units, making it ideal for saving space in power distribution cabinets.

Quick Start Guide (How-To)

Warning: The following steps are a basic guide only. All electrical work must be performed by qualified professional personnel. Before any wiring, ensure the main power is completely disconnected and wait at least 10 minutes for the internal capacitors of the VFD to discharge fully.

Step 1: Installation

Mount the inverter vertically on a sturdy, non-flammable surface, such as a metal mounting plate. Ensure there is sufficient clearance for heat dissipation. Side-by-side installation is permitted.

Step 2: Main Circuit Wiring

Connect the single-phase 220V AC power lines to the inverter’s input terminals

R/L1andS/L2.Connect the three wires of the three-phase asynchronous motor to the inverter’s output terminals

U,V, andW.Securely connect the ground wire to the inverter’s

PE(Protective Earth) terminal.

Step 3: Control Circuit Wiring (for Basic Start/Stop)

Connect one end of an external switch (or button) to the digital input terminal

S1.Connect the other end of the switch to the

COMterminal.Set parameter

P0-02(Command source selection) to “1” (Terminal command channel).Set parameter

P4-00(S1 function selection) to “1” (Forward run).

Step 4: Motor Parameter Setting & Auto-tuning

Upon first power-up, accurately enter the following parameters from your motor’s nameplate:

P1-01: Motor Rated Power (set to 0.4kW)P1-02: Motor Rated Voltage (set to 220V)P1-03: Motor Rated Current (e.g., 2.3A)P1-04: Motor Rated FrequencyP1-05: Motor Rated Speed

For optimal vector control performance, perform a motor auto-tune. Set parameter

P1-37(Motor auto-tuning) to “2” (dynamic auto-tuning) or “3” (static auto-tuning) and start the inverter.

Step 5: Test Run

After confirming all wiring and parameter settings are correct, turn on the main power. Close the external switch connected between S1 and COM. The motor should start rotating in the forward direction. Open the switch, and the motor will stop according to the set deceleration time.

Core Features & Advantages

Ultra-Compact Narrow Body: Features a new narrow body design and compact structure. Compared to older products, the installation size is reduced by 30% and the volume by 45%, saving installation space and reducing distribution costs.

Space-Saving Installation: The design features independent air ducts for efficient, straight-through heat dissipation, which allows for side-by-side installation to maximize use of cabinet space.

High Starting Torque: This AC motor drive is capable of 0.5Hz starting torque at 150% under Sensorless Vector Control (SVC), providing excellent low-speed performance for general-purpose loads.

Robust Overload Capacity: As a G-type drive, it handles 150% of its rated current for 60 seconds and 180% for 3 seconds, ensuring stability during load changes.

Simplified I/O: Designed for simple speed regulation, this model features a streamlined I/O configuration of 4 digital input terminals, 1 analog input, and 1 relay output.

Smart Integrated Functions: Includes a built-in PID controller for process control, a Simple PLC for multi-stage speed running, and Auto-adjust voltage (AVR) to keep output voltage steady when the grid voltage changes.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV200 User Manual.pdf | 1.4MB |