EV200-0007G-S2: Compact 1HP Single Phase VFD | 0.75kW, 220V

Why Choose This 0.75 kW (1HP) 220V Single Phase VFD?

The EV200-0007G-S2 is the definitive solution for users needing to drive 1HP three-phase motors from a standard household outlet while minimizing installation footprint.

Ideal for 1HP Machine Upgrades: This model is perfectly sized for converting fixed-speed 1HP machinery (like drill presses or band saws) to variable speed, offering better control and energy efficiency.

Ultra-Compact Footprint: The narrow body design means you can fit this drive into existing, cramped electrical boxes where traditional, bulkier 1HP drives simply won’t fit.

Reliable in Dusty Environments: Unlike open-chassis drives, the independent air duct helps protect the internal circuit boards from conductive dust found in ceramics or grinding applications.

Cost-Effective Performance: It strips away unnecessary features like a built-in braking unit (not required for this power range) to focus on delivering high-performance vector control at a competitive price point.

Typical Application Fields

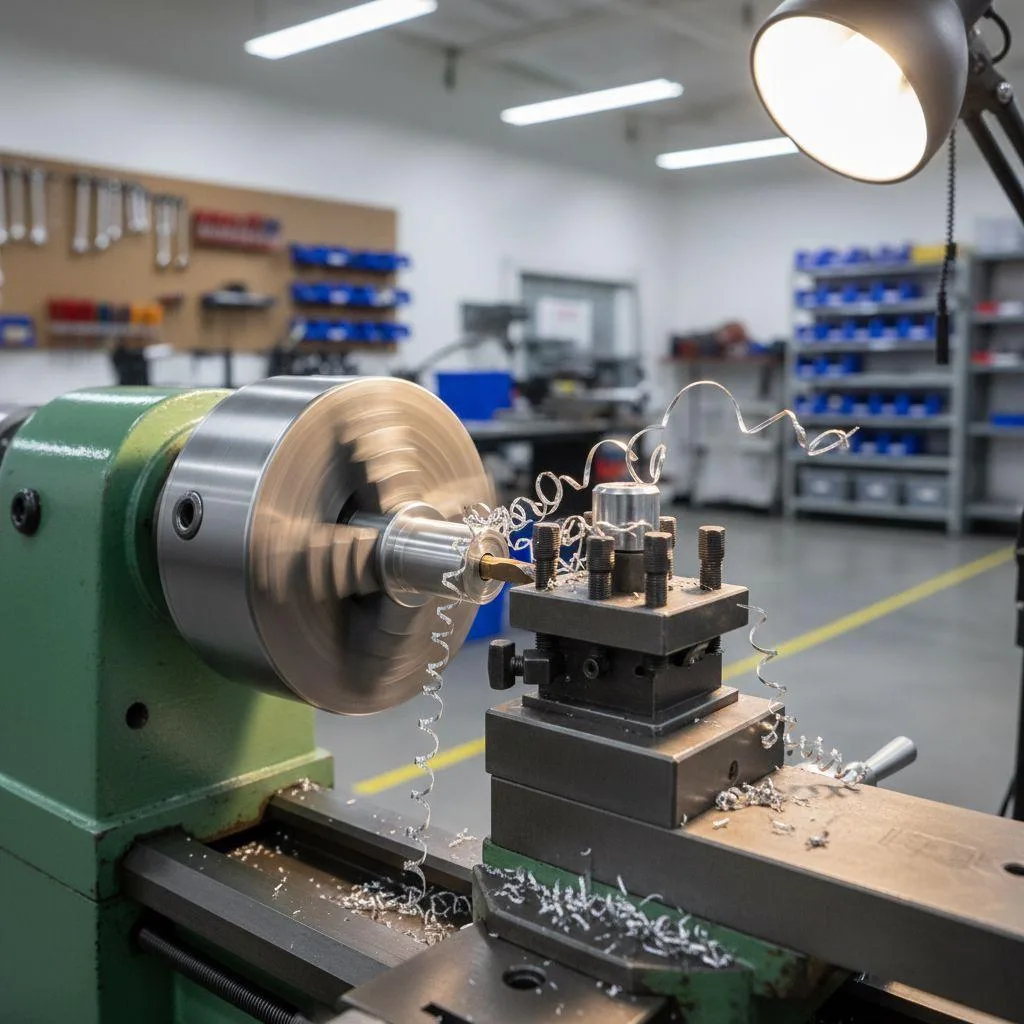

Benchtop Lathes

Provides variable speed control and consistent torque for small metalworking or woodworking lathes, eliminating the need for manual belt changes.

Industrial Sewing Machines

Offers precise speed regulation and rapid start/stop cycles for heavy-duty textile and sewing operations.

Printing Machinery

Controls the feed and roller mechanisms in small offset or screen printing presses where space is limited.

Control Characteristics

Control Mode | without PG Vector(SVC), V/F control |

|---|---|

Highest Frequency | Vector control: 0~500Hz; V/F control: 0~500Hz |

Start Torque | G type: 0.5Hz/150% (SVC) |

Speed Range | 1:100 (SVC) |

Speed Control Accuracy | ±0.5% (SVC) |

Overload Capacity | G type: 150% rated current 60s; 180% rated current 3s |

I/O Specifications

Digital Input | 4 digital input terminals |

|---|---|

Analog Input | 1 analog input terminal |

Relay Output | 1 relay output terminal |

Communication | Supports Modbus, RS85 (Assumed RS485), CANopen, CANlink |

Operating Environment

Installation Site | Indoors, no direct sunlight, no dust, corrosive gases, etc. |

|---|---|

Altitude | Below 1000 meters |

Ambient Temperature | -10°C to +40°C (derating required for 40~50°C) |

Humidity | <95%RH, no condensation |

Structural Dimensions

Dimensions (W x D x H) | 73 x 112.6 x 143 mm |

|---|---|

Installation Size (A x B) | 60 x 129 mm |

Installation Hole | Ф4.4 |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

Can I use this VFD to run a 1HP single-phase motor?

No, absolutely not. The EV200-0007G-S2 is designed to convert a single-phase 220V input into a three-phase 220V output. Connecting a single-phase motor (which has start capacitors) to the output terminals (U, V, W) will damage both the motor and the VFD. You must use a three-phase asynchronous motor.

Does the EV200-0007G-S2 require an external braking resistor?

This specific model (0.75kW) does not have a built-in braking unit, so you cannot directly connect a braking resistor to it. For applications requiring fast stopping, you can use the DC braking function parameters (P6-10 to P6-14) to stop the motor electronically.

What is the recommended input circuit breaker size?

The rated input current for this model is 8.2A. We recommend using a molded case circuit breaker (MCCB) or a fuse rated slightly higher than this, typically around 15A or 20A, to handle the input current without nuisance tripping.

Is the cooling fan always on?

By default, the fan may run continuously, but the EV200 series typically allows for intelligent fan control settings (refer to parameter P8-48) to run the fan only when the unit is running or hot, prolonging fan life and reducing noise in quiet workshop environments.

Quick Start Guide (How-To)

Warning: The following steps are a basic guide. All electrical work must be performed by qualified personnel. Ensure power is off before wiring.

Step 1: Installation

Mount the EV200-0007G-S2 securely on a non-flammable vertical surface. The compact 73mm width allows it to fit into small enclosures or between other devices. Use the 60x129mm mounting hole pattern.

Step 2: Main Circuit Wiring

Connect your Single-Phase 220V supply lines to terminals L1 and L2 (or R/T).

Connect the three wires of your 0.75kW (1HP) three-phase motor to terminals U, V, and W.

Step 3: Control Circuit Wiring

For a simple external run switch, connect a toggle switch between S1 and COM.

For speed control, wire a 1kΩ – 10kΩ potentiometer to the analogue input terminals (+10V, AI, GND).

Step 4: Parameter Setup

Power on the VFD. Navigate to Group P1 and input your motor’s nameplate data (0.75kW, Voltage, Current, Frequency, RPM).

Set P0-02 to “1” to enable the external terminal start switch.

Set P0-03 to “2” (or appropriate value) to enable the potentiometer for speed control.

Step 5: Test Run

Flip the S1 switch. The motor should start smoothly. If it spins backwards, power down and swap any two motor output wires (e.g., U and V).

Core Features & Advantages

High Power Density: Delivers 0.75kW (1HP) of reliable vector control power in a chassis that is only 73mm wide, allowing for maximum performance in minimal cabinet space.

Side-by-Side Mounting: Specifically designed for zero-clearance side-by-side installation, enabling high-density configuration for multi-axis machines like textile winders or printing lines.

Superior Low-Speed Torque: Capable of producing 150% starting torque at 0.5Hz, ensuring powerful and smooth startups for high-inertia loads like pottery wheels or flywheel-driven machinery.

Independent Air Duct Design: Features a straight up-and-down independent cooling channel that separates airflow from electronic components, significantly improving dust resistance in environments like ceramic studios or woodshops.

Versatile Control Interfaces: Equipped with 4 digital inputs, 1 analog input, and 1 relay output, providing the essential connectivity needed for external switches, potentiometers, and sensors.

Compatible Interface: The keypad interface is compatible with the company’s 510 series, simplifying parameter management for users with mixed drive types.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV200 User Manual.pdf | 1.4MB |