EV200-0015G-S2: Compact 1.5kW (2HP) Single Phase Vector VFD | 220V Input

Why Choose This 1.5 kW (2HP) 220V Single Phase VFD?

Perfect for 2HP Motors: This model is precisely rated for 1.5kW (2HP) motors, a standard size for light industrial and serious hobbyist equipment. It provides the full 7.0A output current required to run these motors at peak efficiency.

Retrofit Friendly: Its miniature size (73mm x 143mm x 112.6mm) allows it to fit inside the existing electrical boxes of many machines, such as drill presses or small mills, making it an excellent choice for converting equipment to variable speed.

Cost-Effective Performance: You get professional-grade Vector Control for the price of a basic V/F drive. This ensures your motor runs quieter, cooler, and with better speed stability under varying loads.

Simplified Wiring: The control terminals are spring-loaded or screw-type (depending on batch) and clearly labeled, making the connection of external switches and potentiometers straightforward for installers.

Energy Savings: For fan and pump applications, the variable speed capability can reduce energy consumption by 20-50% compared to running the motor at full speed with a damper or valve.

Typical Application Fields

Textile Machinery

Used in spinning and weaving equipment where multiple small motors are mounted in a row; the narrow body design is a perfect fit here.

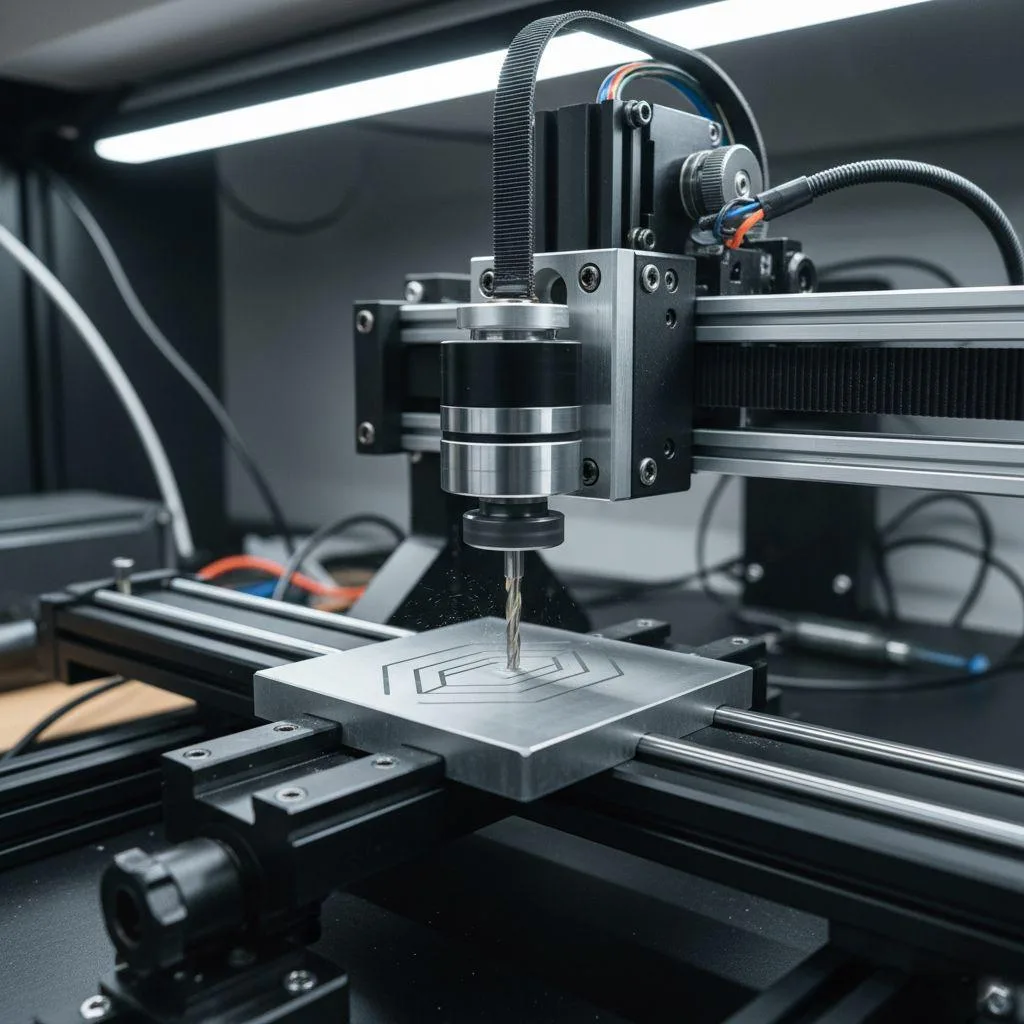

Small CNC Spindles

Drives 1.5kW air-cooled or water-cooled spindles for engraving and sign making, providing high-speed output (up to 500Hz).

Medical Centrifuges

Ensures smooth acceleration and stable high-speed rotation for separating samples in laboratories.

Control Characteristics

Control Mode | without PG Vector(SVC), V/F control |

|---|---|

Highest Frequency | Vector control: 0~500Hz; V/F control: 0~500Hz |

Start Torque | G type: 0.5Hz/150% (SVC) |

Speed Range | 1:100 (SVC) |

Speed Control Accuracy | ±0.5% (SVC) |

Overload Capacity | G type: 150% rated current 60s; 180% rated current 3s |

I/O Specifications

Digital Input | 4 digital input terminals |

|---|---|

Analog Input | 1 analog input terminal |

Relay Output | 1 relay output terminal |

Communication | Supports Modbus, RS85 (Assumed RS485), CANopen, CANlink |

Operating Environment

Installation Site | Indoors, no direct sunlight, no dust, corrosive gases, etc. |

|---|---|

Altitude | Below 1000 meters |

Ambient Temperature | -10°C to +40°C (derating required for 40~50°C) |

Humidity | <95%RH, no condensation |

Structural Dimensions

Dimensions (W x D x H) | 73 x 112.6 x 143 mm |

|---|---|

Installation Size (A x B) | 60 x 129 mm |

Installation Hole | Ф4.4 |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

1. Does the EV200-0015G-S2 have a built-in braking chopper?

No, the 1.5kW model (and all EV200 models from 0.4kW to 2.2kW) does not have a built-in braking unit. You cannot connect an external braking resistor. For applications requiring fast stopping, you should utilize the DC Injection Braking function (Parameters P6-10 to P6-14) or adjust your deceleration ramp to prevent over-voltage faults.

2. What are the exact dimensions of this unit?

The EV200-0015G-S2 is extremely compact. It measures 143mm in Height, 73mm in Width, and 112.6mm in Depth. The mounting hole centers are 129mm (Vertical) x 60mm (Horizontal). Its small size allows it to replace almost any older 2HP drive.

3. Can I use this VFD to run a lathe with a 2HP motor?

Yes, this is an excellent application. The Vector Control (SVC) mode will maintain steady RPM even as the cutting load changes, providing a superior surface finish compared to pulley systems. You can also wire an external Forward/Reverse switch and a speed potentiometer for convenient control panel access.

4. How do I wire the single-phase input?

Connect your Single Phase 220V Live and Neutral wires to terminals L1 and L2 (sometimes labeled R and S). Leave the T terminal empty. Connect the motor’s three wires to U, V, and W. Always ensure the Ground is connected to the PE terminal.

Quick Start Guide (How-To)

Warning: Ensure power is disconnected before wiring. Wait 10 minutes after powering off for capacitors to discharge.

Step 1: Mechanical Installation

Mount the VFD vertically using M4 screws. Ensure there is at least 100mm of clearance above and below for airflow. Thanks to the independent air duct, you can mount units side-by-side with no horizontal gap.

Step 2: Wiring

Power: Input to L1, L2. Ground to PE.

Motor: Output to U, V, W. (Ensure motor is wired for 220V).

Control (Optional): Wire a start switch between S1 and GND.

Step 3: Parameter Setup Power up the unit and set the following for a standard 1.5kW 50Hz motor:

P1-01: 1.5 (Motor Power)

P1-02: 220 (Motor Voltage)

P1-03: 7.0 (Motor Current – check nameplate!)

P1-04: 50.00 (Frequency)

P1-05: 1440 (RPM)

Step 4: Auto-Tuning (Essential for Vector Control)

Set P0-01 = 0 (SVC Mode).

Set P1-37 = 1 (Static Tune) or 2 (Rotary Tune).

Press RUN. The VFD will measure motor characteristics.

Step 5: Run

Set P0-02 = 1 (Terminal Control) if using external switches, or 0 (Keypad Control) to use the Run button.

Adjust speed using the knob or Up/Down arrows (depending on P0-03 setting).

Core Features & Advantages

73mm Ultra-Narrow Footprint: With a width of only 73mm, this VFD is 30% smaller than previous generations. It supports zero-clearance side-by-side installation, allowing you to pack more drives into a smaller electrical cabinet, drastically reducing enclosure costs.

High Low-Speed Torque (SVC): Delivers 150% starting torque at 0.5Hz (P0-01=0). This is crucial for applications like dough mixers or conveyor belts that require immediate power to move heavy loads from a standstill.

Independent Air Duct Design: The drive employs a straight-through vertical cooling channel that isolates the heat sink from the electronic components. This prevents dust and oil mist from accumulating on the PCB, ensuring reliability in harsh environments like woodworking shops or textile factories.

Optimized I/O Configuration: Features 4 programmable digital inputs, 1 analog input (0-10V/0-20mA), and 1 relay output. This lean configuration handles all essential start/stop, multi-speed, and fault monitoring tasks without the complexity of unused ports.

Robust Motor Protection: Provides comprehensive protection, including Phase Loss, Overcurrent, Overvoltage, and Motor Short Circuit Detection. The Instantaneous Stop Non-Stop function keeps the drive running during brief power fluctuations by utilizing regenerative energy.

Built-in Automation Functions: Includes a Simple PLC for executing up to 16-speed automatic cycles and a PID Controller for maintaining constant pressure or flow in pump and fan applications.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV200 User Manual.pdf | 1.4MB |