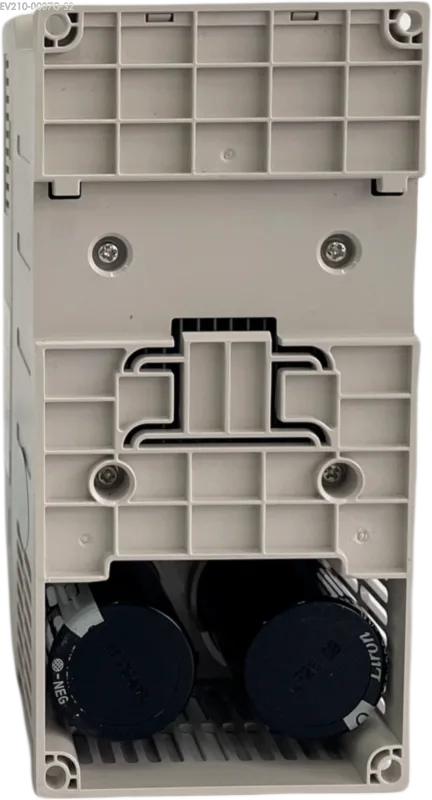

EV210-0007G-S2: Compact High-Performance Vector VFD | 0.75kW, 220V

Why Choose This 0.75kW (1HP) 220V Compact Vector VFD?

Choosing the right drive is critical. This specific 0.75kW (1HP) VFD is the perfect solution when your application needs more power than the 0.4kW model but still requires the ultra-compact EV210 footprint.

- More Power, Same Compact Size: This drive delivers 0.75kW (1HP) of power while retaining the same 72mm wide miniature chassis as the 0.4kW model. It’s the ideal upgrade for small machines needing to drive a 1HP motor.

- Precision for Demanding Machinery: This AC motor speed controller excels in applications beyond simple fans. Its vector control is essential for machine tools, textile winders, or packaging machines where the motor must maintain exact speed and torque under varying loads.

- Quiet, Reliable Operation: The adjustable carrier frequency provides low noise operation, a critical feature for equipment installed in noise-sensitive environments like laboratories or small workshops.

- Cost-Effective Automation: By integrating PID, PLC, and RS-485 communication, this compact vector VFD can simplify your system design, eliminating the need for external controllers and reducing total system cost and complexity.

Typical Application Fields

Textile Machinery

A perfect textile machine VFD for small winders, spinning frames, and knitting machines requiring precise tension and speed synchronization.

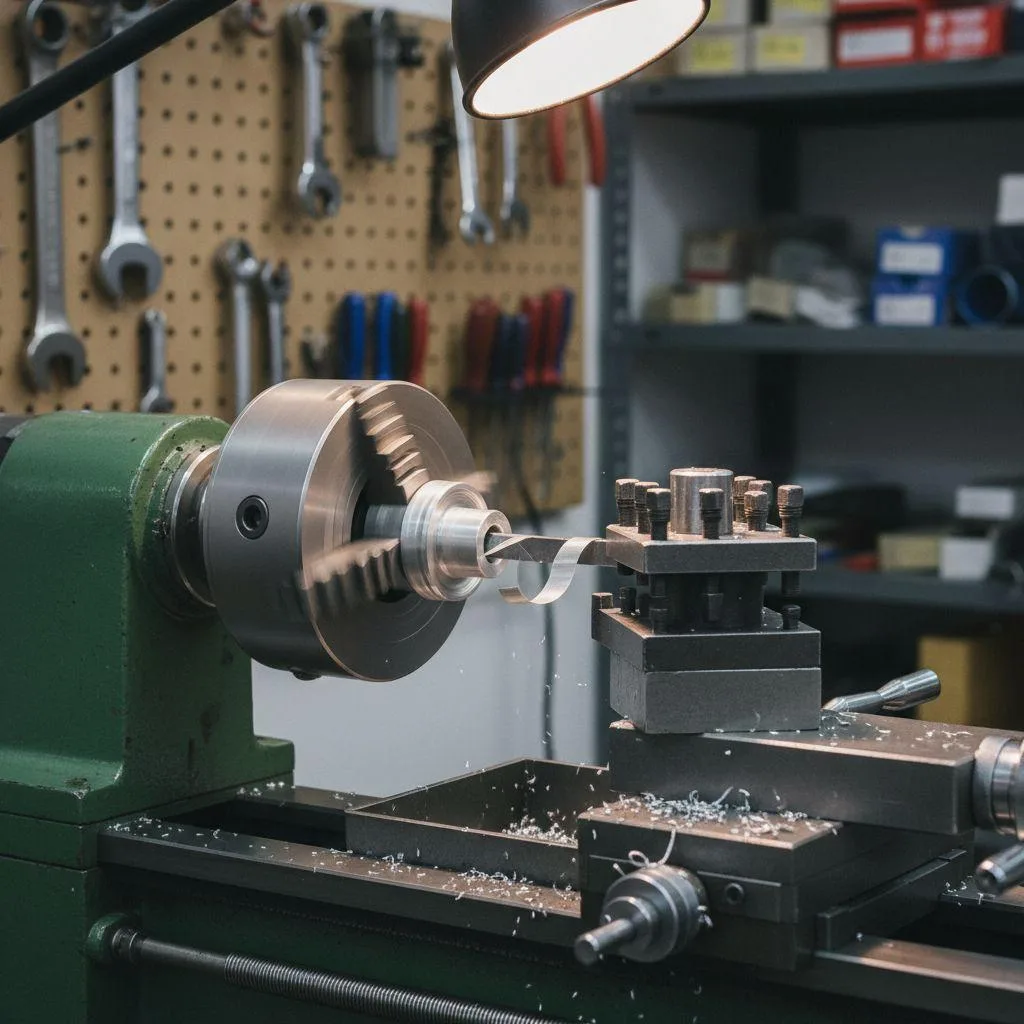

Machine Tools

Provides the precise sensorless vector control needed for small machine tools , grinders, and lathes that require stable torque from a 1HP motor.

Packaging Machinery

An excellent packaging machine VFD for compact labelers, fillers, and wrappers where its small size and responsive control are critical for high-speed, accurate operation.

Control Characteristics

Control Mode | High-Performance Current Vector Control , Sensorless Vector Control (SVC), V/F Control |

|---|---|

Highest Frequency | Vector Control: 0~500Hz; V/F Control: 0~500Hz |

Carrier Frequency | 0.5KHz ~ 16.0KHz (Adjustable, for low noise operation) |

Speed Tracking | Features “speed tracking speed restart function” |

DC Braking | Start Frequency: 0.00 ~ Max Freq; Braking Time: 0.0 ~ 100.0s |

Accel/Decel Time | 0.0s ~ 6500.0s |

I/O Specifications

Analog Input | 1 channel (0~10V / 0~20mA) |

|---|---|

Analog Output | 1 channel (0~10V / 0~20mA) |

Digital Output | 1 Programmable Relay Output (TA, TC) |

Communication | Standard RS-485 (Modbus) |

Operating Environment

Installation Site | Indoors, no direct sunlight, no dust, corrosive gases, etc. |

|---|---|

Altitude | Below 1000 meters |

Ambient Temperature | -10°C to +40°C |

Humidity | <95%RH, no condensation |

Structural Dimensions

Dimensions (W x D x H) | 72 x 105 x 146 mm |

|---|---|

Installation Size (A x B) | 63.0 x 136.5 mm |

Installation Hole | φ2.3 |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

1. What is the difference between the 0.75kW EV210 and the 0.75kW EV200 VFD?

The key difference is the control method. The EV200 is a “small inverter” designed for simple speed regulation. The EV210 is a “high-performance miniature inverter” that integrates advanced current vector control. Choose the EV200 for simple applications like small fans. Choose the EV210 for applications needing precise speed, high starting torque, or stable control under load, such as machine tools or packaging.

2. Why is the Rated Input Current (8.2A) so much higher than the Output Current (4.0A)?

This is normal for a single-phase input VFD. The drive draws power from a single AC phase (creating 8.2A of input current) and uses it to create a balanced three-phase output (at 4.0A per phase) for the motor. Always size your input-side wiring and breakers for the 8.2A input rating.

3. Does this 0.75kW VFD require an external braking resistor?

It depends on your application. If you need to stop a high-inertia load quickly, you will need one. The recommended specification for the EV210-0007G-S2 is an 80W, 150Ω resistor. This connects to terminals P+ and PB. For light-duty applications, DC braking (parameter P6-11) may be sufficient.

4. Can I use the built-in PID to control a 1HP water pump?

Yes. The built-in PID controller is perfect for this. You can connect a 0-10V or 0-20mA pressure sensor to the analog input (AI) and set a target pressure. The VFD will automatically adjust the pump’s speed to maintain that pressure, which is also highly energy-efficient.

Quick Start Guide (How-To)

Warning: The following steps are a basic guide only. All electrical work must be performed by qualified professional personnel. Before any wiring, ensure the main power is completely disconnected and wait at least 10 minutes for the internal capacitors of the VFD to fully discharge.

Step 1: Installation

Mount the VFD vertically on a sturdy, non-flammable surface (like a metal backplate) or a DIN rail in a well-ventilated cabinet. Ensure sufficient clearance for airflow. The compact 72mm width allows for high-density, side-by-side installation.

Step 2: Main Circuit Wiring

- Connect your Single Phase 220V AC power lines to the inverter’s input terminals S/L1 and T/L2.

- Connect the three wires of your 0.75kW (1HP) three-phase asynchronous motor to the inverter’s output terminals U, V, and W.

- Securely connect the ground wire to the inverter’s PE (Protective Earth) terminal.

Step 3: Control Circuit Wiring (for Basic 2-Wire Start/Stop)

- Connect one end of an external switch (or button) to the digital input terminal X1.

- Connect the other end of the switch to the common terminal COM.

Step 4: Motor Parameter Setting & Configuration

- Upon first power-up, set the VFD parameters to match your motor’s nameplate :

- Set P1-01 (Motor Rated Power) to 0.75 (kW).

- Set P1-02 (Motor Rated Voltage) to 220 (V).

- Set P1-03 (Motor Rated Current) based on your motor’s nameplate.

- Set P1-04 (Motor Rated Frequency) (e.g., 50 or 60 Hz).

- Set P1-05 (Motor Rated Speed) (e.g., 1440, 2800, etc.).

- To enable the 2-wire start/stop from Step 3:

- Set P0-02 (Command source) to “1” (Terminal command channel).

- Set P4-00 (X1 function selection) to “1” (Forward run).

- For optimal vector control, perform a motor auto-tune (set P1-37, see manual for details).

Step 5: Test Run

After confirming all wiring and settings, turn on the main power. Close the external switch connected between X1 and COM. The motor should start and run in the forward direction. Open the switch, and the motor will decelerate and stop.

Core Features & Advantages

- Advanced Vector Control in a Miniature Body: This drive integrates a high-performance current vector inverter into a compact frame. It provides outstanding torque characteristics (150% at 0.25Hz) and precise speed control (SVC), far superior to standard V/F control.

- Ultra-Compact, Space-Saving Design: Measuring only 72mm wide and 105mm deep, this miniature vector VFD is designed for high-density DIN-rail mounting in crowded control cabinets, saving critical installation space.

- Quiet & Stable Performance: Engineered for low noise operation, the VFD features an adjustable carrier frequency (0.5KHz ~ 16.0KHz) to minimize high-frequency motor noise. The Automatic Voltage Control (AVR) function ensures stable performance even with grid fluctuations.

- Integrated PID & PLC Functions: Features a built-in PID controller for simple, closed-loop process control (e.g., managing pressure, flow, or tension) and an Easy PLC function for basic multi-segment speed operation.

- Robust System Protection: Offers comprehensive protection functions, including overcurrent, overvoltage, undervoltage, overheat, and overload. Includes a speed tracking restart function for a smooth, safe recovery from a momentary power loss.

- Flexible System Integration: Standard built-in RS485 communication (Modbus protocol) allows this 0.75kW VFD to be easily integrated into larger automation systems. Flexible I/O includes analog inputs (0-10V/0-20mA) and a programmable relay output.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV210 User Manual.pdf | 1.3MB |