EV510A-0004G-S2: Single Phase Vector VFD | 0.4kW, 220V

Why Choose This 0.4 kW (0.5HP) 220V Single Phase Vector VFD?

Choosing the right drive is crucial for performance and reliability. This specific 0.4 kW (0.5HP) VFD is the ideal solution when your application requires more than just basic speed control.

- Precision in a Small Package: While many small VFDs only offer simple V/F control, this model provides advanced vector control. This is essential for applications needing stable speed under varying loads, high starting torque for demanding machinery, and overall smoother, more precise motor performance.

- Energy and Cost Efficiency: By precisely matching the motor’s speed to the application’s demand, this VFD significantly reduces energy consumption compared to running a motor at full speed, leading to lower operational costs. The integrated features, like the built-in PLC and PID controller, can also eliminate the need for external control components, saving on hardware costs and simplifying your system design.

- Increased Equipment Lifespan: The soft-start and stop capabilities reduce mechanical stress on motors, gearboxes, and belts. This gradual acceleration minimizes wear and tear, prolonging the life of your entire machinery and reducing maintenance needs.

- Versatility for Complex Applications: With a rich set of I/O terminals and standard Modbus communication, this drive is built for integration. It’s perfect for creating smart, automated systems for conveyors, pumps, and specialized machinery where feedback and external control are necessary.

Typical Application Fields

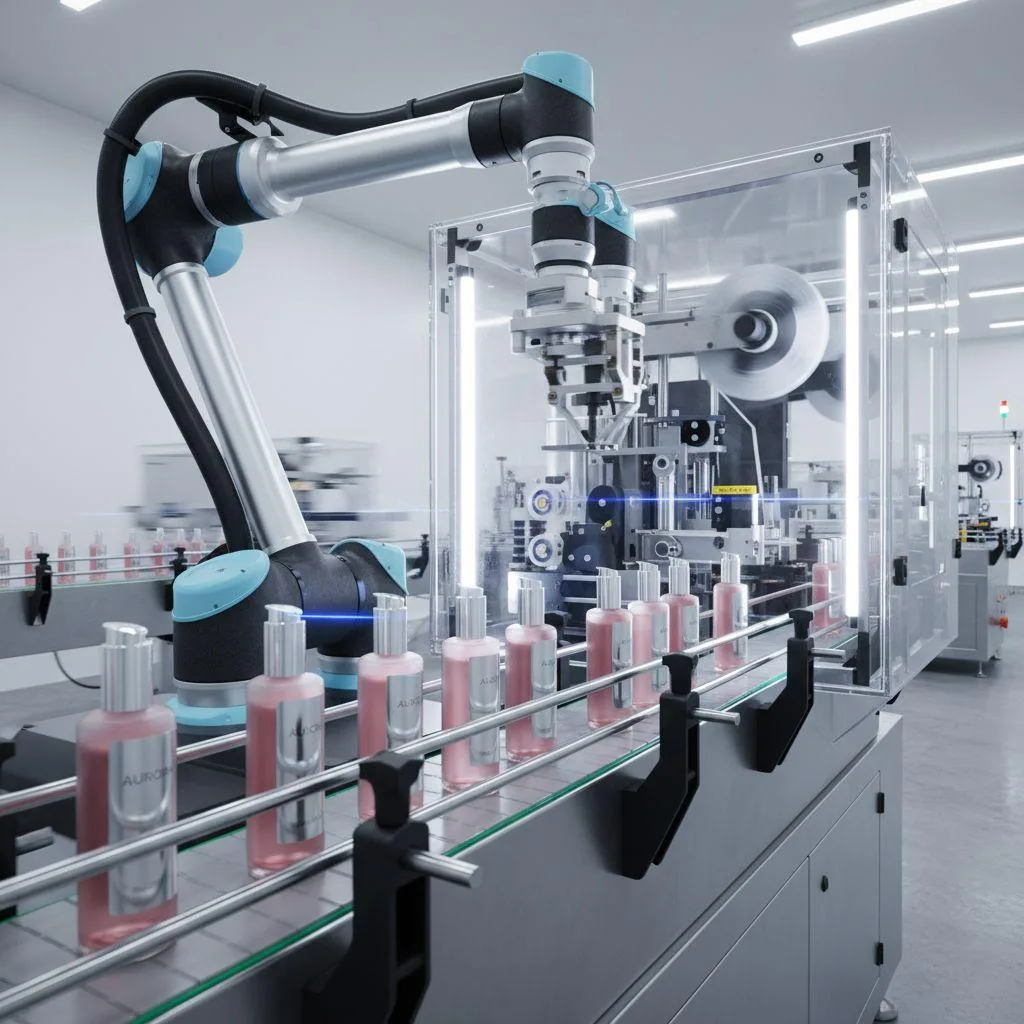

Light Packaging & Labeling Equipment

An excellent choice for a packaging machine VFD or for automatic labeling machine motor control systems.

Laboratory & Medical Equipment

Used for analytical instrument stirrers and medical centrifuge VFD applications that require smooth, vibration-free laboratory equipment motor control.

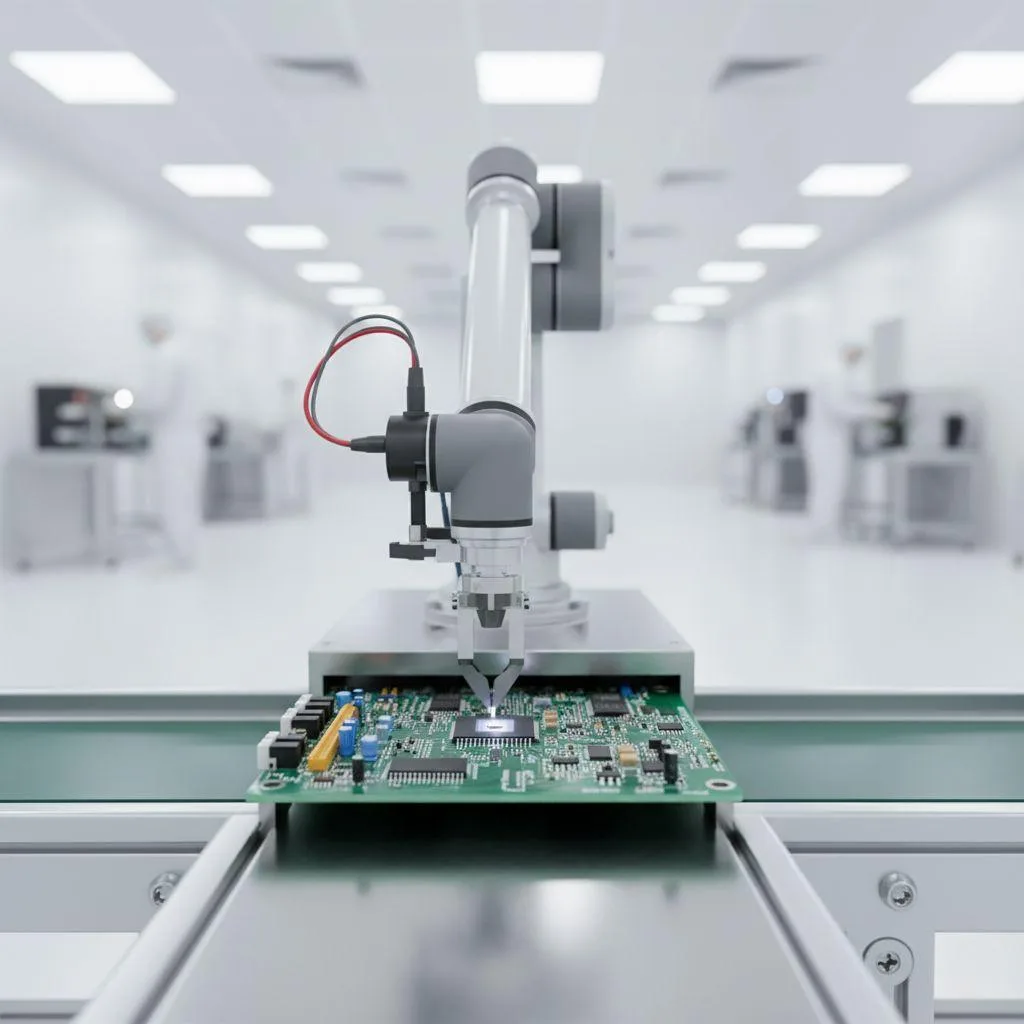

Electronics Manufacturing

For small assembly lines, plug-in machines, and other precision equipment.

Control Characteristics

Control Mode | Sensorless Vector Control (SVC), Closed-loop Vector Control (FVC), V/F Control |

|---|---|

Highest Frequency | Vector Control: 0~500Hz; V/F Control: 0~500Hz |

Start Torque | 0.5Hz / 150% (in SVC mode) |

Speed Range | 1:100 (SVC) |

Speed Accuracy | ±0.5% (SVC) |

Overload Capacity | 150% rated current for 60s; 180% rated current for 3s |

I/O Specifications

Digital Input | 7 channels, with 1 channel supporting up to 100KHz high-speed pulse input |

|---|---|

Analog Input | 2 channels, supporting 0~10V voltage or 0~20mA current input |

Digital/Pulse Output | 1 high-speed pulse output channel (0~100kHz) |

Relay Output | 2 relay output channels |

Analog Output | 2 channels, supporting 0~20mA current or 0~10V voltage output |

Communication | Standard RS-485 (Modbus), supports CANlink |

Operating Environment

Installation Site | Indoors, no direct sunlight, no dust, corrosive gases, etc. |

|---|---|

Altitude | Below 1000 meters |

Ambient Temperature | -10°C to +40°C (derating required for 40~50°C) |

Humidity | <95%RH, no condensation |

Structural Dimensions

Dimensions (W x D x H) | 112 x 118 x 180 mm |

|---|---|

Installation Size (A x B) | 101 x 171 mm |

Installation Hole | φ4.6 |

Weight | 1.3 kg |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

1. What is the difference between V/F control and Sensorless Vector Control (SVC)?

V/F control is a basic method for motor speed regulation, suitable for general-purpose loads like fans and pumps where precise torque control is not critical. Sensorless Vector Control (SVC) is a more advanced algorithm that provides precise control over the motor’s torque without needing an encoder. It delivers higher starting torque at low speeds and better speed stability, making it ideal for more demanding equipment.

2. How do I select the right VFD model for my motor?

The selection of a VFD primarily depends on three core parameters: the motor’s rated power, rated voltage, and the application’s load type. For example, in the model EV510A-0004G-S2, “0004” indicates it’s for a 0.4kW motor, “G” stands for general-purpose load (suitable for constant torque applications), and “S2” signifies a single-phase 220V input. Always ensure the VFD’s rated current is greater than or equal to the motor’s rated current.

3. What are the installation environment requirements for the inverter?

To ensure stable operation and a long service life, the inverter should be installed indoors in a well-ventilated area away from direct sunlight. The ambient temperature should be between -10°C and +40°C, with humidity below 95%RH and no condensation. The installation altitude should be below 1000 meters, and the area should be free from dust, corrosive gases, and flammable materials.

4. What happens if there is a momentary power outage?

This series of inverters features a “ride-through” (Instantaneous stop, not stop) function. In the event of a brief power grid voltage drop or momentary outage, the VFD can use the energy fed back from the motor to compensate for the voltage loss, allowing it to continue running for a short period and preventing production interruptions.

Quick Start Guide (How-To)

Warning: The following steps are a basic guide only. All electrical work must be performed by qualified professional personnel. Before any wiring, ensure the main power is completely disconnected and wait at least 10 minutes for the internal capacitors of the VFD to fully discharge.

Step 1: Installation

Mount the inverter vertically on a sturdy, non-flammable surface, such as a metal mounting plate. Ensure there is sufficient clearance around the unit (at least 100mm recommended) for proper ventilation and heat dissipation.

Step 2: Main Circuit Wiring

- Connect the single-phase 220V AC power lines to the inverter’s input terminals

RandS(L1/L2). - Connect the three wires of the three-phase asynchronous motor to the inverter’s output terminals

U,V, andW. - Securely connect the ground wire to the inverter’s

PE(Protective Earth) terminal.

Step 3: Control Circuit Wiring (for Basic Start/Stop)

- Connect one end of an external switch (or button) to the digital input terminal

S1. - Connect the other end of the switch to the common terminal

COM. - Set parameter

P0-02(Command source selection) to “1” (Terminal command channel). - Set parameter

P4-00(S1 function selection) to “1” (Forward run).

Step 4: Motor Parameter Setting & Auto-tuning

- Upon first power-up, accurately enter the following parameters from your motor’s nameplate:

P1-01: Motor Rated Power (set to 0.4kW)P1-02: Motor Rated Voltage (set to 220V)P1-03: Motor Rated CurrentP1-04: Motor Rated FrequencyP1-05: Motor Rated Speed

- For optimal vector control performance, perform a motor auto-tune. Set parameter

P1-37(Motor auto-tuning method) to “2” (dynamic auto-tuning) and start the inverter.

Step 5: Test Run

After confirming all wiring and parameter settings are correct, turn on the main power. Close the external switch connected between S1 and COM. The motor should start rotating in the forward direction. Open the switch, and the motor will stop according to the set deceleration time.

Core Features & Advantages

- Precise Low-Speed Control Performance: Employs advanced sensorless vector control (SVC) technology to achieve smooth and precise motor control even under light loads, providing up to 150% starting torque at just 0.5Hz for low-speed high-torque applications.

- Sufficient Safety Margin: Designed for general-purpose (G-type) loads, it can withstand 150% of the rated current for 60 seconds and 180% for 3 seconds, providing ample safety protection for small vector control VFD applications against unexpected load fluctuations.

- Highly Integrated Control Functions: Features a built-in PLC, multi-speed operation, and VFD with PID control, allowing engineers to implement more complex automation sequences without an external controller, which is especially suitable for space and cost-sensitive applications.

- Comprehensive System Protection: Provides multiple protection functions, including overcurrent, overvoltage, undervoltage, overheat, overload, and output phase loss, with power-on motor short-circuit detection to ensure safe and reliable operation.

- Flexible I/O Configuration: Standard on this single-phase 220V VFD are 7 digital inputs (including one high-speed pulse), 2 analog inputs, 2 relay outputs, and 2 analog outputs, offering powerful expansion capabilities for connecting sensors and actuators, including Modbus RS485 VFD communication.

- Compact, Efficient Design: Optimized structural design makes it smaller than the previous generation, weighing only about 1.3 kg, effectively saving installation space and facilitating integration into compact equipment.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV510A User Manual.pdf | 1.8MB |