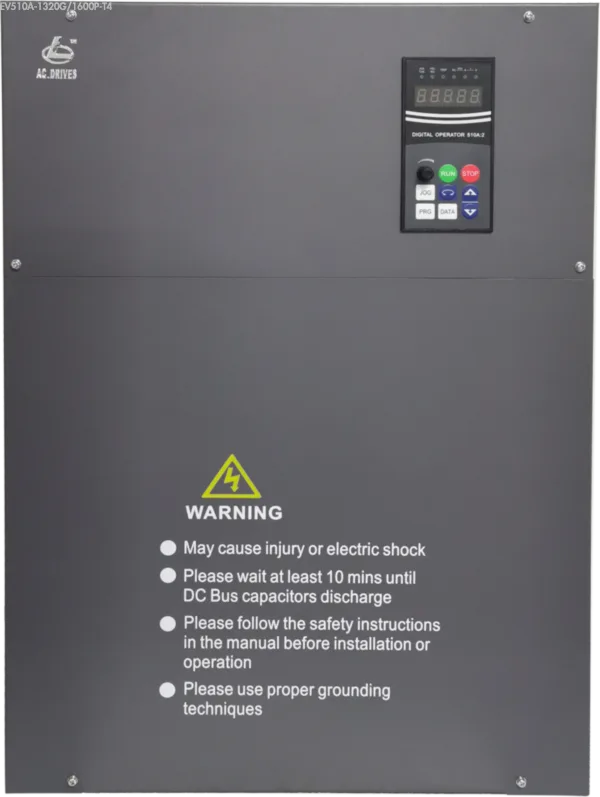

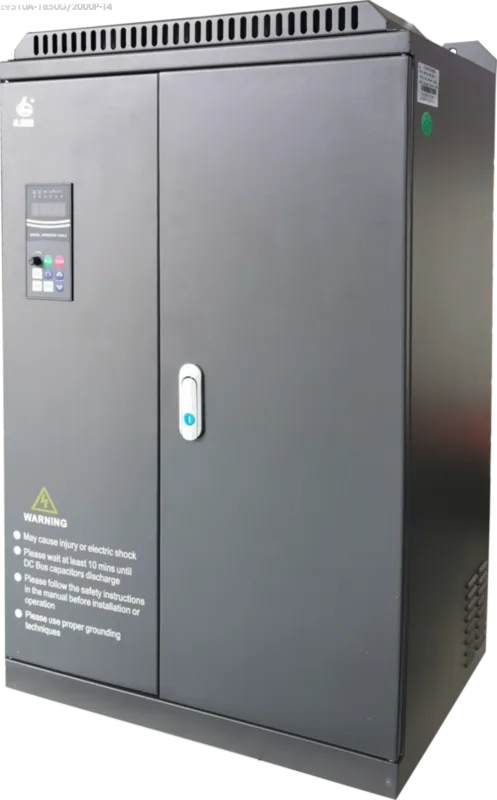

EV510A-1320G/1600P-T4 High-Performance Vector 132kW(175HP) / 160kW(215HP) 380V VFD

Parameter | G-Type: 0037G | P-Type: 0055P |

|---|---|---|

Motor Power | 3.7 kW / 5 HP (Constant Torque) | 5.5 kW / 7.5 HP (Variable Torque) |

Output Current | 9.0 A | 9.0 A |

Rated Input Current | 10.5 A | 10.5 A |

Power Capacity | 5.9 kVA | 5.9 kVA |

Input Power | Three-Phase 380V (±15%) | Three-Phase 380V (±15%) |

EV510A-1320G/1600P-T4: The Industrial Powerhouse

The EV510A-1320G/1600P-T4 is a heavy-duty Variable Frequency Drive (VFD) engineered for large-scale industrial automation. As a high-power member of the EV510A series, it offers a “smaller in size, more compact in structure” design compared to traditional soft starters or older drives, without compromising on power.

This drive features a flexible G/P Dual-Rating, allowing a single unit to adapt to two massive power tiers:

G-Type (Constant Torque): Rated for 132kW (175 HP). Designed for heavy machinery with high inertia and resistance, such as rock crushers, ball mills, and large extruders. It provides robust overload protection of 150% rated current for 60 seconds.

P-Type (Variable Torque): Rated for 160kW (215 HP). Optimized for centrifugal loads like municipal water pumps and large ventilation fans, offering significant energy savings and 120% overload capability.

Designed for stability, it includes “Instantaneous stop not stop” technology, ensuring continuous operation during brief power grid fluctuations by utilizing motor feedback energy.

Why Choose the EV510A-1320G/1600P-T4?

Soft Starter Replacement: Replace traditional soft starters with this VFD to gain full speed control, energy savings, and high starting torque that soft starters cannot provide.

Grid Resilience: The “Instantaneous stop not stop” function is vital for large facilities where momentary power dips could otherwise halt a 132kW production line, causing massive downtime.

Expansion Capability: The accessible DC bus (+) and (-) allows for the integration of regenerative braking units or common DC bus configurations for multi-drive energy sharing.

Dual-Purpose Inventory: Stocking one drive covers both 132kW heavy-duty crushers and 160kW ventilation fans, streamlining maintenance spares.

Typical Application Fields

Ball Mills & Crushers

These loads have massive inertia. The VFD’s high starting torque (150% @ 0.5Hz) breaks static friction, while the vector control optimizes grinding efficiency.

Large Extruders

For large-scale plastic or rubber extrusion, consistent torque is required to push viscous materials through dies. This drive ensures uniform product quality.

Mine Ventilation Fans

Critical for safety in mining. The drive controls 160kW main ventilation fans, adjusting airflow based on demand to significantly reduce electricity costs compared to dampers.

Control Characteristics

Parameter | G-Type: 1320G | P-Type:1600P |

|---|---|---|

Control Mode | V/F Control, Open-loop Vector (SVC), Closed-loop Vector (FVC) | V/F Control, Open-loop Vector (SVC), Closed-loop Vector (FVC) |

Overload Capacity | 150% Rated Current 60s; 180% Rated Current 3s | 120% Rated Current 60s; 150% Rated Current 3s |

Starting Torque (SVC) | 0.5Hz / 150% | 0.5Hz / 100% |

Speed Range (FVC) | 1:1000 | 1:1000 |

Steady Speed Precision (FVC) | ±0.02% | ±0.02% |

Digital Inputs (DI) | 7 channels (1 @ 100kHz) | 7 channels (1 @ 100kHz) |

Analog Inputs (AI) | 2 channels (AI1: 0-10V, AI2: 0-10V/0-20mA) | 2 channels (AI1: 0-10V, AI2: 0-10V/0-20mA) |

Structural Dimensions

Dimensions (W x D x H) | 454 x 310 x 670 mm |

|---|---|

Installation Size (A x B) | 300 x 650 mm |

Installation Hole | φ9 |

Weight | 67 kg |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

- Q: How do I connect a braking resistor to this 132kW drive?

- A: You cannot connect a resistor directly. For this power range (132kW), you must install an External Braking Unit (connected to terminals

+and-) and then connect the resistor to that unit .

- A: You cannot connect a resistor directly. For this power range (132kW), you must install an External Braking Unit (connected to terminals

- Q: What is the benefit of the DC Reactor terminals P1 and (+)?

- A: These terminals allow you to install a DC Reactor. This smooths the DC bus ripple, improves the input power factor, and protects the drive’s rectifier bridge from power surges.

- Q: Can this drive handle a 160kW motor?

- A: Yes, if the load is “Variable Torque” (P-Type), such as a fan or centrifugal pump. Set parameter P9-76 to ‘2’ (P model) to configure the drive for 160kW operation.

- Q: What is the physical size of this unit?

- A: It is a wall-mountable unit measuring 400mm (W) x 835mm (H) x 382mm (D) and weighs approximately 107 kg.

Quick Start Guide (How-To)

Guide 1: Wiring the Main Circuit (132kW) For high-power units, correct terminal identification is crucial:

- Input: Connect 3-phase power to terminals R, S, T.

- Output: Connect the motor to terminals U, V, W.

- DC Bus: Terminals (+) and (-) are for external braking units. Do NOT connect a resistor directly here.

- Reactor: Terminals P1 and (+) are for a DC reactor. If not using one, ensure the factory configuration (often a jumper) is correct as per specific wiring instructions.

Guide 2: Configuring for 160kW Fan (P-Type) To use the drive with a 160kW fan:

- Power On: Ensure safety protocols are followed.

- Enter Parameters: Press

PRGto enter the menu. - Set Mode: Navigate to P9-76 (Frequency converter G/P). Change the value to 2 (P model).

- Verify: The drive will now optimize its overload curve (120% for 60s) for fan applications.

Guide 3: Connecting External Control (Start/Stop):

- Wiring: Connect a switch between terminal S1 and COM.

- Parameter: Set P0-02 = 1 (Terminal command channel).

- Operation: Closing the switch will now start the drive; opening it will stop it.

Core Features & Advantages

Superior Vector Control Technology

- Precision Control: Operates in Open-loop Vector (SVC), Closed-loop Vector (FVC), or V/F modes.

- Torque Response:

- G-Type: Achieves 150% torque at 0.5Hz (SVC) or 180% at 0Hz (FVC), essential for starting heavy loads without stalling.

- Speed Accuracy: Maintains ±0.02% speed accuracy in FVC mode for synchronized processes.

High-Power Architecture

- DC Bus Access: Unlike smaller units, this model features dedicated (+) and (-) terminals. This allows for the connection of an External Braking Unit, which is critical for rapidly stopping high-inertia loads.

DC Reactor Ready: Terminals P1 and (+) are provided for connecting a DC reactor to improve power factor and reduce harmonics.

Robust Thermal Design: Independent air duct design ensures efficient heat dissipation for high-kilowatt operation

Intelligent Process Management

- Built-in PID: Integrated process control for maintaining constant pressure or flow in large piping systems.

Multi-Speed Operation: Supports up to 16-speed stages via Simple PLC or digital terminals, ideal for complex cycling duties like industrial washing or mixing.

Quick Current Limit: The “Digger” feature automatically limits torque and current to prevent tripping during sudden load spikes.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV510A User Manual.pdf | 1.8MB |