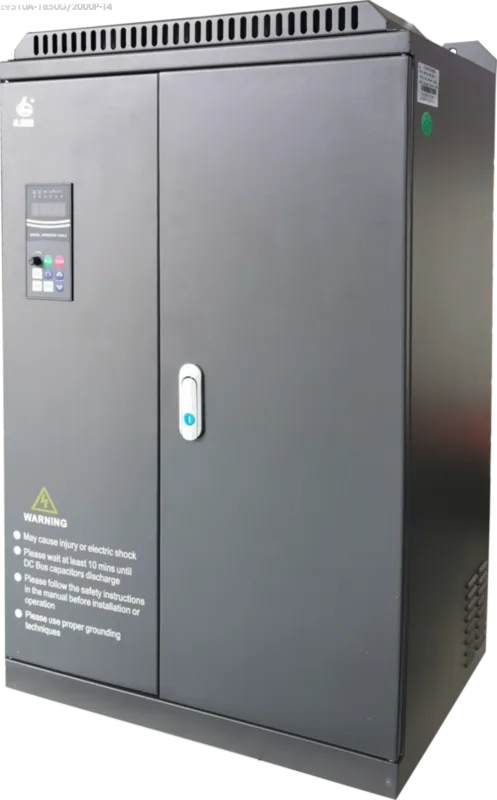

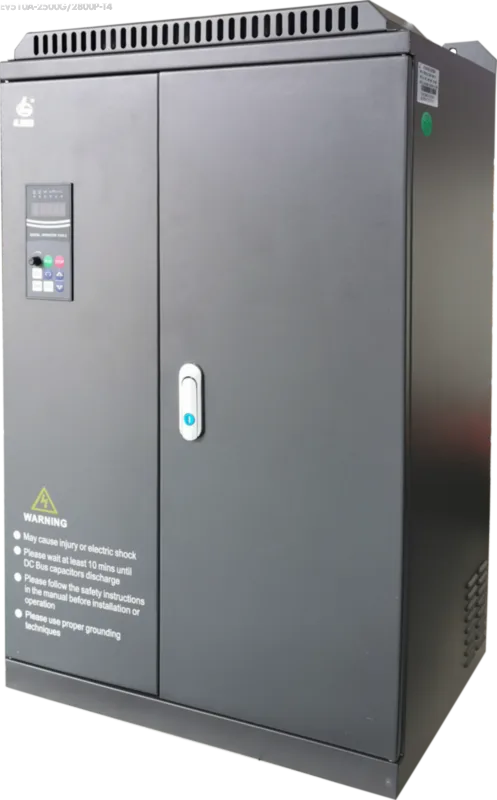

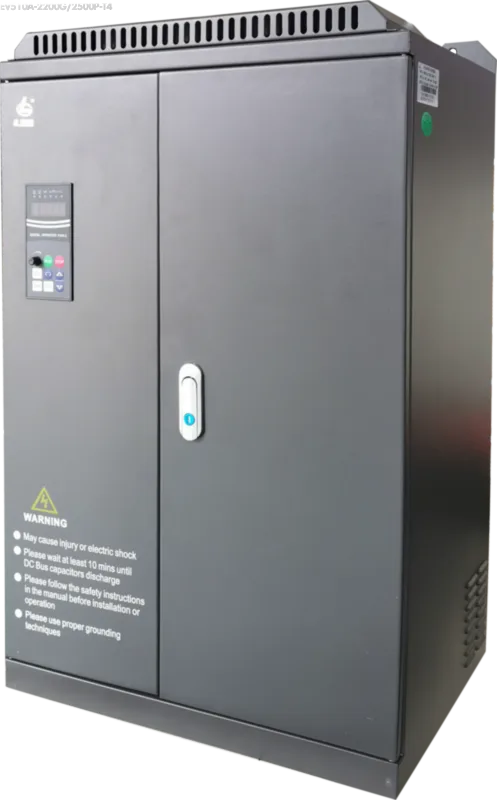

EV510A-1850G/2000P-T4 | 185kW(250HP) / 200kW(275HP) 380V Dual Rated Vector VFD

Parameter | G-Type: 0037G | P-Type: 0055P |

|---|---|---|

Motor Power | 3.7 kW / 5 HP (Constant Torque) | 5.5 kW / 7.5 HP (Variable Torque) |

Output Current | 9.0 A | 9.0 A |

Rated Input Current | 10.5 A | 10.5 A |

Power Capacity | 5.9 kVA | 5.9 kVA |

Input Power | Three-Phase 380V (±15%) | Three-Phase 380V (±15%) |

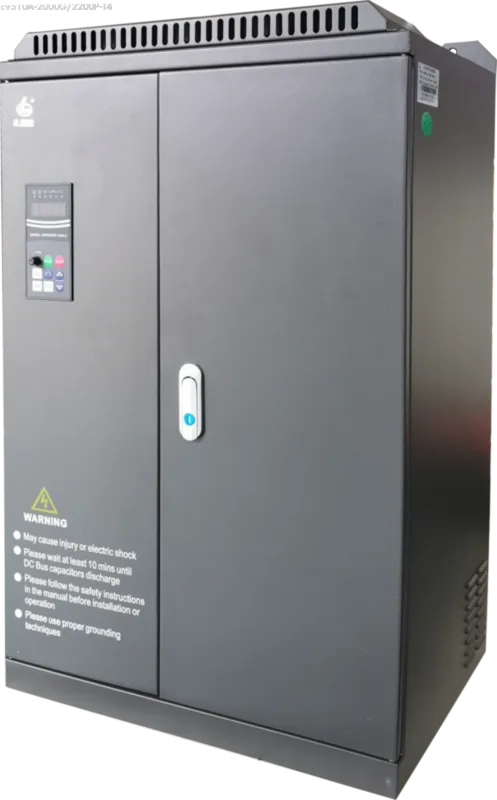

EV510A-1850G/2000P-T4: High-Capacity VFD for Maximum Power and Uptime

The EV510A-1850G/2000P-T4 is a high-performance vector frequency inverter engineered to meet the most demanding high-power applications in industrial automation. The cornerstone of this drive is its G/P Dual-Rated capability, which allows a single unit to be expertly configured for two different operational modes :

- G-Type (Constant Torque): Rated for 185kW (approx. 250 HP) “General” (G-type) loads, such as large-scale extruders, crushers, or rolling mills. This mode is defined by its high starting torque and robust overload capacity.

- P-Type (Variable Torque): Rated for 200kW (approx. 275 HP) “Pump or fans” (P-type) loads. This mode is optimized for energy efficiency in applications like centrifugal pumps and large-scale ventilation.

This strategic dual-rating simplifies inventory for system integrators and provides a standardized, high-performance control platform. As an enhanced version of the EV510 series, the EV510A is “smaller in size, more compact in structure… and more stable in performance”. It utilizes a “high-performance current vector control” algorithm for outstanding precision and integrates essential reliability features like “Instantaneous stop not stop” (power loss ride-through) and a “Quick current-limit function” to maximize system uptime.

Why Choose the EV510A-1850G/2000P-T4?

In the 185-200kW power class, the EV510A-1850G/2000P-T4 provides an intelligent combination of power, precision, and value.

- Maximize ROI with Dual-Rating: The G/P dual-rating is this drive’s most intelligent feature. It eliminates the need to source and stock two separate AC drives for a 185kW heavy-duty machine and a 200kW fan. The EV510A-1850G/2000P-T4 handles both, reducing inventory costs and simplifying procurement.

- Built for Reliability: For critical processes, reliability is paramount. The “Instantaneous stop not stop” function provides essential ride-through for brief power sags, while the “Quick Current-limit” actively prevents nuisance trips from load shocks, keeping your operation running.

- Modern, Compact Footprint: As the upgraded EV510A version, this drive is “smaller in size, more compact in structure, and more stable in performance”. This saves valuable cabinet real estate and contributes to a lower Total Cost of Ownership (TCO) through enhanced reliability.

- Integrated Process Control: This is more than a simple motor spinner. With powerful Sensorless Vector Control (SVC) for high-torque tasks and a “Built-in PID” controller for process loops, this single drive can manage a wide range of sophisticated automation tasks without needing an external PLC.

Typical Application Fields

Plastic Extruders

Plastic extruders demand high, constant torque to turn the screw and melt plastic. The 185kW G-Type rating with SVC provides stable speed control, which is critical for uniform product diameter and quality.

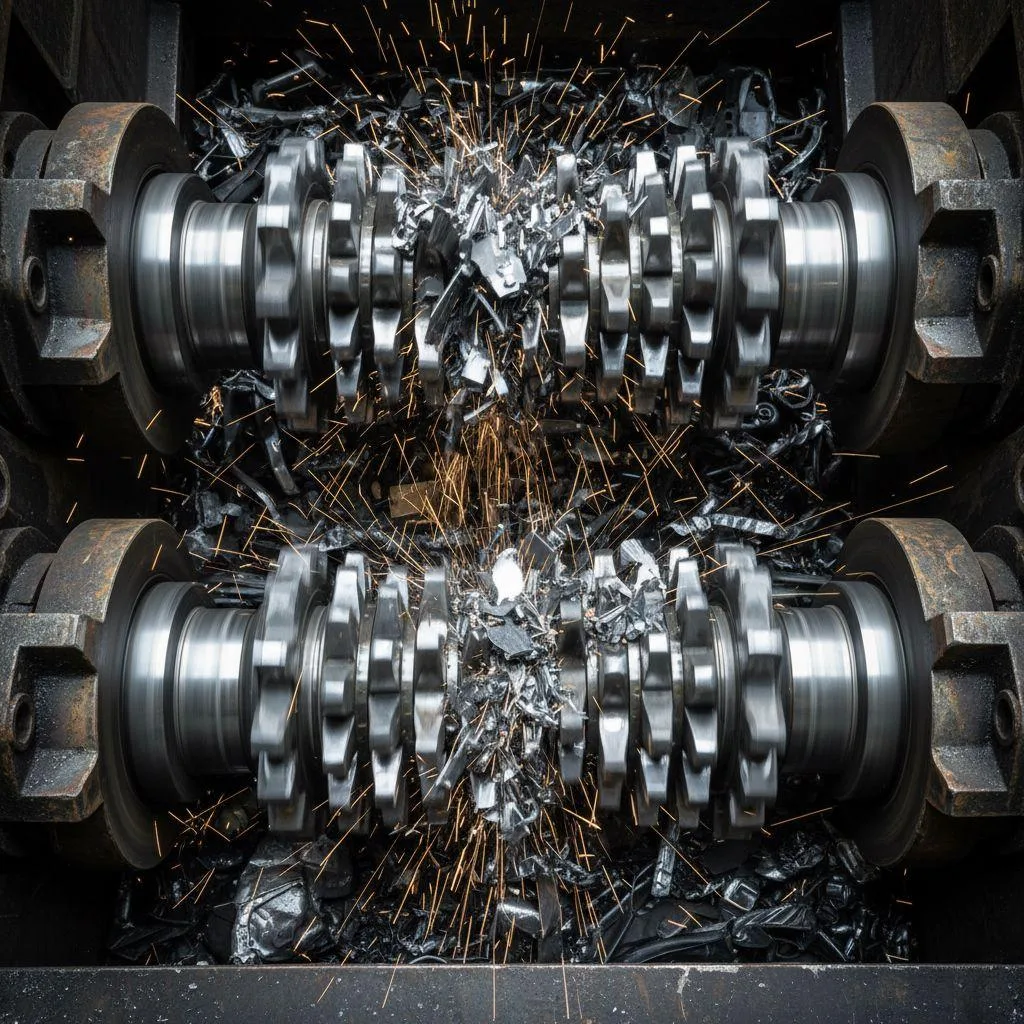

Industrial Shredders

The 250 HP G-Type rating delivers the extreme torque and 150% overload capacity required for industrial shredders to process tough materials like plastic, wood, or metal scrap.

Wastewater Aeration Blowers

Powers 200kW (275 HP) aeration blowers. The P-Type mode offers significant energy savings, while the PID control can be used to maintain precise dissolved oxygen levels in the treatment basins.

Control Characteristics

Parameter | G-Type: 1850G | P-Type:2000P |

|---|---|---|

Control Mode | V/F Control, Open-loop Vector (SVC), Closed-loop Vector (FVC) | V/F Control, Open-loop Vector (SVC), Closed-loop Vector (FVC) |

Overload Capacity | 150% Rated Current 60s; 180% Rated Current 3s | 120% Rated Current 60s; 150% Rated Current 3s |

Starting Torque (SVC) | 0.5Hz / 150% | 0.5Hz / 100% |

Speed Range (FVC) | 1:1000 | 1:1000 |

Steady Speed Precision (FVC) | ±0.02% | ±0.02% |

Digital Inputs (DI) | 7 channels (1 @ 100kHz) | 7 channels (1 @ 100kHz) |

Analog Inputs (AI) | 2 channels (AI1: 0-10V, AI2: 0-10V/0-20mA) | 2 channels (AI1: 0-10V, AI2: 0-10V/0-20mA) |

Structural Dimensions

Dimensions (W x D x H) | 520 x 382 x 835 mm |

|---|---|

Installation Size (A x B) | 400 x 810 mm |

Installation Hole | φ13 |

Weight | 107 kg |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

Q: What do G-Type and P-Type mean on the EV510A-1850G/2000P-T4?

A: This specifies the drive’s dual-rating, selectable via parameter P9-76. G-Type (General) is rated for 185kW Constant Torque applications (like extruders) and provides a high overload capacity (150% for 60s). P-Type (Pump) is rated for 200kW Variable Torque applications (like fans) with a standard overload (120% for 60s).

Q: Is the EV510A different from the EV510?

A: Yes, the EV510A is the upgraded version. It is “smaller in size, more compact in structure, and more stable in performance”.

Q: What is “Instantaneous stop not stop”?

A: This is a power loss ride-through function. If the power sags, the drive uses the motor’s feedback energy to “compensate for voltage-drop to keep running for a short time,” preventing a shutdown.

Q: Can this VFD run two different motors?

A: Yes, but not simultaneously. It has a “Multi-motor Switch” function. You can program two motor profiles (in parameter groups P1 and A2) and switch between them using a digital input or parameter P0-24.

Q: What are the most common fault codes?

A: Common VFD fault codes include FU02 (Over current during acceleration), FU06 (Over voltage during deceleration), FU09 (Under voltage), and FU14 (Inverter Overheat).

Q: Does this drive have a PID controller?

A: Yes, it features a powerful “Built-in PID” controller. This allows it to receive an analog feedback signal (like a pressure or temperature sensor) and automatically manage a closed-loop process. The parameters are in group PA.

Quick Start Guide (How-To)

This guide is intended to help you quickly set up and diagnose the EV510A Variable Frequency Drive based on the user manual.

Guide 1: Commissioning – How to Auto-Tune the Motor

To achieve the best performance in Sensorless Vector Control (SVC) mode (when P0-01=0), you must first perform a motor auto-tune.

- Input Motor Nameplate Data: In parameter group P1, enter the following values from your motor’s nameplate:

- P1-01: Motor 1 Rated power (kW)

- P1-02: Motor 1 Rated voltage (V)

- P1-03: Motor 1 Rated current (A)

- P1-04: Motor 1 Rated frequency (Hz)

- P1-05: Motor 1 Rated speed (rpm)

- Select Auto-Tune Mode: Set parameter P1-37 to choose the tuning type:

- 1: Asynchronous machine static self-learning

- 2: Asynchronous machine dynamic complete self-learning (Requires motor to be uncoupled)

- Execute Auto-Tune: After selecting the mode, press the RUN key to begin the auto-tuning process.

Guide 2: Process Control – How to Set Up PID

Using the built-in PID (Group PA) allows you to create a constant pressure pump system without an external PLC.

- Set PID Feedback Source: Wire your 4-20mA pressure transducer to analog input AI2. Set the AI2 jumper on the control board to ‘I’ (current). Then, set parameter PA-02 = 1 (PID feedback source = AI2).

- Set PID Target Value (Setpoint): Set PA-00 = 0 (PID reference source = PA-01). Then, enter your target pressure percentage in PA-01 (e.g., 50.0%).

- Adjust PID Gains:

- PA-05 (Proportional Gain Kp1): Default is 20.0. Adjust to speed up or slow down the response.

- PA-06 (Integral Time Ti1): Default is 2.00s. Adjust to eliminate steady-state error.

- Set Feedback Loss Detection: To prevent the pump from running at max speed if the sensor wire breaks, set PID feedback loss detection.

- PA-26: Set detection level (e.g., 10.0%).

- PA-27: Set detection time (e.g., 2.0s). This will trigger fault FU31 (PID feedback lost).

Core Features & Advantages

The design of the EV510A-1850G/2000P-T4 integrates high-accuracy control, robust protection, and versatile I/O, with all specifications sourced directly from the official technical manuals.

High-Accuracy Control & Vector Performance

- Advanced Control Modes: Features versatile control modes including V/F, Sensorless Vector Control (SVC), and high-precision Closed-loop Vector Control (FVC) via an optional PG card.

- Powerful Starting Torque: The advanced vector algorithm delivers exceptional torque at low speeds.

- G-Type (SVC): Achieves 150% of rated torque at just 0.5Hz.

- G-Type (FVC): Achieves 180% of rated torque at 0Hz.

- P-Type (SVC): Achieves 100% of rated torque at 0.5Hz.

- Exceptional Precision: In Closed-loop vector control (FVC) mode, the drive achieves a 1:1000 speed range with a steady-speed precision of ±0.02%. In SVC mode, the speed range is 1:100 with a precision of ±0.5%.

- High-Speed Output: Supports an output frequency range of 0~500Hz, ideal for high-speed motor applications.

Robust Reliability & Uptime

- Instantaneous Stop Not Stop (Ride-Through): A core design principle for maximum uptime. During a momentary power loss, the drive uses the motor’s regenerative energy to “compensate for voltage drop to keep running for a short time,” preventing a costly shutdown.

- Quick Current-limit Function: Automatically “Reduce over current error on max extent” to protect the inverter from sudden load shocks and minimise over-current faults, ensuring continuous operation.

- Heavy-Duty Overload Capacity: Provides optimised overload protection for both G-Type and P-Type loads :

- G-Type (185kW): 150% of rated current for 60 seconds; 180% for 3 seconds.

- P-Type (200kW): 120% of rated current for 60 seconds; 150% for 3 seconds.

Flexible System Integration

- Comprehensive I/O: Features a full suite of programmable I/O for complex automation.

- 7 programmable Digital Inputs (DI): one of which supports up to 100KHz high-speed pulse input.

- 2 programmable Analog Inputs (AI): AI1 (0~10V) and AI2 (0~10V or 0~20mA).

- 2 Relay Outputs: (TA/TB/TC and RA/RC).

- 2 programmable Analogue Outputs (AO): Both support 0~20mA or 0~10V output.

- Multi-Motor Switching: Capable of storing two independent motor parameter sets (in groups P1 and A2) and switching between them via a digital input, allowing one VFD to control two different motors.

- Built-in PID Controller: Includes a full-featured PID controller (Group PA) to “realise process control closed-loop system conveniently,” perfect for managing constant pressure or flow without an external PLC.

- Standard Communications: Equipped with RS-485 (Modbus) and supports CAN link buses for easy system integration.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV510A User Manual.pdf | 1.8MB |