EV210-0004G-S2: Compact High-Performance Vector VFD | 0.4kW, 220V

Why Choose This 0.4kW (0.5HP) 220V Compact Vector VFD?

Choosing the right drive is critical. This specific 0.4kW (0.5HP) VFD is the ideal solution when your application is too demanding for a basic mini-drive, but the installation space is too small for a full-sized vector drive.

- The “Compact Vector” Hybrid Advantage: This is the perfect hybrid drive. When a basic miniature AC drive (like the EV200, designed for “simple speed regulation” ) lacks the precision for your load, the EV210-0004G-S2 provides the advanced vector control you need in the compact form factor you want.

- Precision for Complex Micro-Machinery: This AC motor speed controller excels in applications beyond simple fans. Its vector control is essential for máquinas-ferramentas , enroladores têxteis , ou máquinas de embalagem onde o motor deve manter a velocidade e o binário exatos sob cargas variáveis.

- Quiet, Reliable Operation: The adjustable carrier frequency provides low noise operation , a critical feature for equipment installed in noise-sensitive environments like laboratories or small workshops.

- Cost-Effective Automation: By integrating PID and RS485 communication , this compact vector VFD can simplify your system design, eliminating the need for external controllers and reducing total system cost and complexity.

Campos de aplicação típicos

Máquinas têxteis

A perfect textile machine VFD for small winders, spinning frames, and knitting machines requiring precise tension and speed synchronization in a compact form factor.

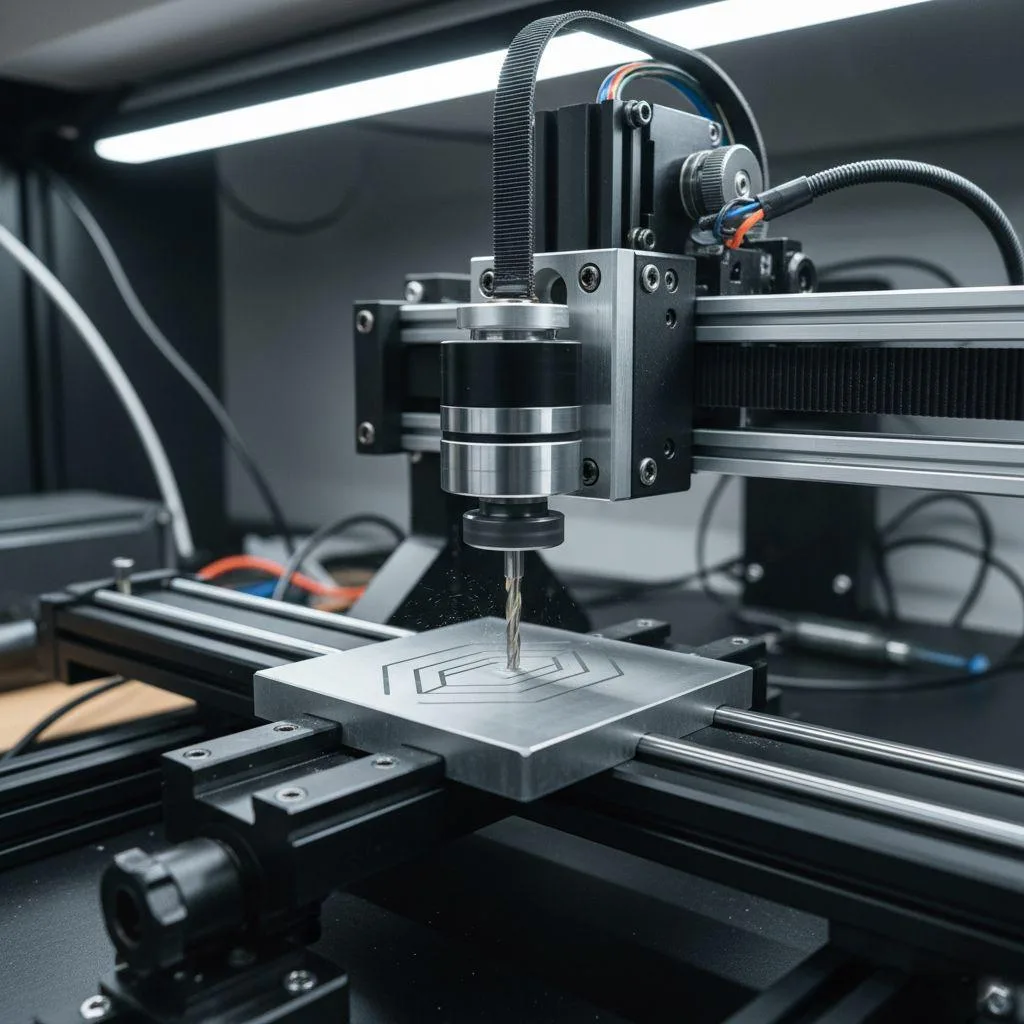

CNC & Machine Tools

Provides the precise sensorless vector control needed for CNC engraving spindles, small machine tools , grinders, and lathes that require stable torque across their speed range.

Laboratory & Medical

Its low noise operation and precision make it suitable for medical centrifuges or advanced laboratory mixers and samplers.

Caraterísticas de controlo

Modo de controlo | Controlo vetorial de corrente de elevado desempenho, Controlo vetorial sem sensores (SVC), Controlo V/F |

|---|---|

Frequência mais elevada | Controlo vetorial: 0~500Hz; Controlo V/F: 0~500Hz |

Frequência portadora | 0,5KHz ~ 16,0KHz (Ajustável, para funcionamento com baixo ruído) |

Controlo de velocidade | Caraterísticas “função de controlo da velocidade e de reinício da velocidade” |

Travagem DC | Frequência de arranque: 0,00 ~ Frequência máxima; Tempo de travagem: 0,0 ~ 100,0s |

Tempo de aceleração/desaceleração | 0.0s ~ 6500.0s |

Especificações de E/S

Entrada analógica | 1 canal (0~10V / 0~20mA) |

|---|---|

Saída analógica | 1 canal (0~10V / 0~20mA) |

Saída digital | 1 Saída de relé programável (TA, TC) |

Comunicação | RS-485 padrão (Modbus) |

Ambiente operacional

Local de instalação | No interior, sem luz solar direta, sem poeiras, gases corrosivos, etc. |

|---|---|

Altitude | Abaixo de 1000 metros |

Temperatura ambiente | -10°C a +40°C |

Humidade | <95%RH, sem condensação |

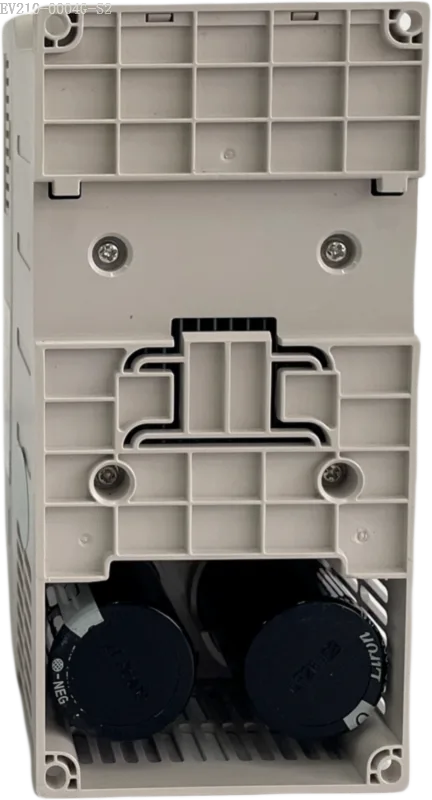

Dimensões estruturais

Dimensões (L x P x A) | 72 x 105 x 146 mm |

|---|---|

Tamanho da instalação (A x B) | 63,0 x 136,5 mm |

Furo de instalação | φ2.3 |

Garantia de qualidade

Este produto é desenvolvido e fabricado pela Nanjing Oulu Electric Corp, Ltd. Como uma empresa nacional de alta tecnologia centrada na automação industrial e nas novas energias, temos uma equipa de I&D experiente e instalações de produção avançadas, dedicadas a fornecer produtos e soluções fiáveis e de alta qualidade a clientes de todo o mundo.

Perguntas frequentes (FAQ)

1. What is the main difference between the 0.4kW EV210 and the 0.4kW EV200 VFD?

The key difference is the control method and positioning. The EV200 is a “small inverter” designed for regulação simples da velocidade. The EV210 is a “high-performance miniature inverter” that integrates advanced current vector control. Choose the EV200 for simple applications like small fans or basic conveyors. Choose the EV210 for applications needing precise speed, high starting torque, or stable control under load, such as machine tools or packaging.

2. Can I use this 0.4kW VFD for a CNC or machine tool spindle motor?

Yes, the EV210-0004G-S2 is an excellent choice for small machine tool spindles. Its sensorless vector control provides stable torque even at low speeds, which is crucial for cutting. Furthermore, its adjustable high-carrier frequency (up to 16.0KHz) ensures low noise operation , reducing the “whine” from the motor.

3. What is the benefit of the ‘speed tracking restart’ function?

This function allows the VFD to smoothly “catch” a motor that is already spinning (e.g., a fan coasting after a brief power outage) and return it to the set speed without a harsh start or tripping on overcurrent. This is critical for reliable, uninterrupted operation in automated systems.

4. How does the built-in PID controller work?

The built-in PID allows the VFD to automatically regulate motor speed to maintain a process variable. For example, you can connect a pressure sensor (as an analog input) and set a target pressure. The VFD will then speed up or slow down a small pump to perfectly maintain that pressure, all without needing an external PLC.

Guia de início rápido (Como fazer)

Aviso: Os passos seguintes são apenas um guia básico. Todos os trabalhos eléctricos devem ser realizados por pessoal profissional qualificado. Antes de qualquer instalação eléctrica, certifique-se de que a alimentação principal está completamente desligada e aguarde pelo menos 10 minutos para que os condensadores internos do VFD se descarreguem completamente.

Passo 1: Instalação

Mount the VFD vertically on a sturdy, non-flammable surface (like a metal backplate) or a DIN rail in a well-ventilated cabinet. Ensure sufficient clearance for airflow. The compact 72mm width allows for high-density, side-by-side installation.

Passo 2: Cablagem do circuito principal

- Ligue as suas linhas de alimentação monofásicas de 220 V CA aos terminais de entrada S/L1 e T/L2 do inversor.

- Connect the three wires of your 0.4kW (0.5HP) three-phase asynchronous motor to the inverter’s output terminals U, V, and W.

- Ligue com segurança o fio terra ao terminal PE (Protective Earth) do inversor.

Passo 3: Fiação do circuito de controlo (para arranque/paragem básico de 2 fios)

- Ligue uma extremidade de um interruptor externo (ou botão) ao terminal de entrada digital X1.

- Ligar a outra extremidade do interrutor ao terminal comum COM.

- (This setup uses X1 for a simple “Run” command in 2-wire mode).

Etapa 4: Definição e configuração dos parâmetros do motor

- Ao ligar pela primeira vez, defina os parâmetros do VFD para corresponder à placa de identificação do seu motor:

- Set P1-01 (Motor Rated Power) to 0.4 (kW).

- Defina P1-02 (Tensão nominal do motor) para 220 (V).

- Defina P1-03 (corrente nominal do motor) com base na placa de identificação do motor.

- Defina P1-04 (Frequência nominal do motor) (por exemplo, 50 ou 60 Hz).

- Defina P1-05 (Velocidade nominal do motor) (por exemplo, 1440, 2800, etc.).

- Para ativar o arranque/paragem de 2 fios a partir do Passo 3:

- Set P0-02 (Command source) to “1” (Terminal command channel).

- Set P4-00 (X1 function selection) to “1” (Forward run).

- For optimal vector control performance, perform a motor auto-tune (set P1-37, see manual for details).

Etapa 5: Execução do teste

Após confirmar toda a fiação e configurações, ligue a alimentação principal. Feche o interruptor externo conectado entre X1 e COM. O motor deve ligar e funcionar na direção para a frente. Abra o interruptor e o motor irá desacelerar e parar.

Principais caraterísticas e vantagens

- Advanced Vector Control in a Miniature Body: This drive integrates a high-performance current vector inverter into a compact frame. It provides outstanding torque characteristics and precise speed control (SVC), far superior to standard V/F control , making it ideal for dynamic loads.

- Ultra-Compact, Space-Saving Design: Measuring only 72mm wide and 105mm deep , this miniature vector VFD is designed for high-density DIN-rail mounting in crowded control cabinets, saving space and reducing overall machine footprint.

- Quiet & Stable Performance: Engineered for low noise operation, the VFD features an adjustable carrier frequency (0.5KHz ~ 16.0KHz) to minimize high-frequency motor noise, making it suitable for laboratory or light commercial environments. The Automatic Voltage Control (AVR) function ensures stable performance even with grid fluctuations.

- Integrated PID & PLC Functions: Features a built-in PID controller and Easy PLC function, enabling simple closed-loop process control (e.g., managing pressure, flow) and basic multi-segment speed operation.

- Reliable System Protection: Offers comprehensive protection functions , including overcurrent, overvoltage, undervoltage, overheat, and overload. Includes a speed tracking restart function for a smooth, safe recovery from a momentary power loss.

- Flexible System Integration: Standard built-in RS485 communication (Modbus protocol) allows this 0.4kW VFD to be easily integrated into larger automation systems. Flexible I/O includes analog inputs (0-10V/0-20mA) and a programmable relay output.

Ficheiro | Tamanho | Ação |

|---|---|---|

Guia de seleção de VFDs.pdf | 4.2MB | |

VFD EV210 Manual do utilizador.pdf | 1.3MB |