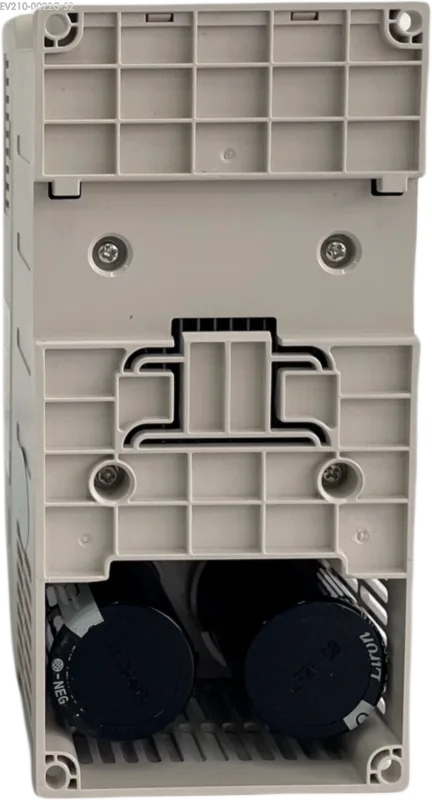

EV210-0022G-S2: VFD monofásico miniatura de alto torque, 2,2kW, 220V

Why Choose This 2.2 kW (3HP) 220V Single Phase VFD?

When panel space is as critical as performance, this specific 2.2 kW (3HP) VFD is the superior choice. While other drives offer this power rating, the EV210-0022G-S2 is engineered for machine builders and retrofitters who need full vector control performance in the smallest possible package.

- Maximum Power, Minimum Space: The EV210-0022G-S2 provides 2.2kW (3HP) of power in a slim 72mm chassis. It’s the perfect solution for running 3HP (or smaller) three-phase motors from a 220V single-phase supply in crowded control cabinets.

- Superior Low-Speed Control: While many compact drives only offer basic V/F control, this model provides advanced sensorless vector control. This is essential for applications like machine tools, wire drawing, and small conveyors that need high torque from a standstill (150% at 0.25Hz).

- Integrated & Cost-Effective: By integrating features like a PID controller and RS-485 Modbus, this drive saves you money. You can automate simple pump or fan systems without needing an external PLC, reducing hardware cost, simplifying wiring, and saving space.

- Reliable Protection: The EV210 series features advanced overcurrent and overvoltage suppression algorithms, preventing nuisance trips during operation and keeping your machinery running reliably.

Campos de aplicação típicos

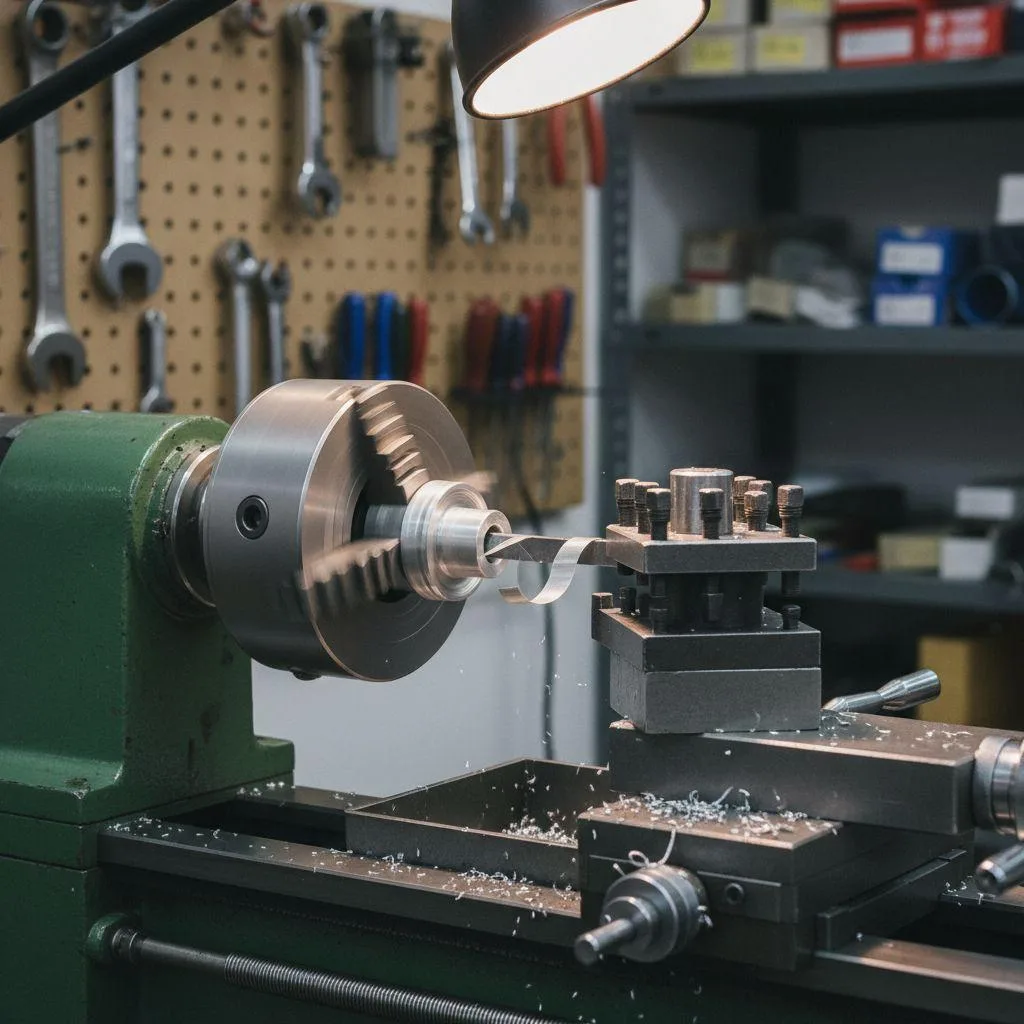

Máquinas-ferramentas

Ideal para pequenos tornos, rebarbadoras e máquinas de perfuração como VFD para máquinas-ferramenta, proporcionando um controlo preciso da velocidade e do binário num formato compacto.

Desenho de têxteis e fios

Um excelente VFD para máquinas têxteis ou para trefilagem, em que o elevado binário de arranque (150% a 0,25Hz) é fundamental para lidar com a tensão e a inércia do material a partir de uma paragem próxima.

Bombas e ventiladores

A smart choice for fan and pump VFD applications up to 2.2kW, using the built-in PID to maintain constant pressure or flow for significant energy savings.

Caraterísticas de controlo

Modo de controlo | Controlo vetorial de corrente de elevado desempenho, Controlo vetorial sem sensores (SVC), Controlo V/F |

|---|---|

Frequência mais elevada | Controlo vetorial: 0~500Hz; Controlo V/F: 0~500Hz |

Frequência portadora | 0,5KHz ~ 16,0KHz (Ajustável, para funcionamento com baixo ruído) |

Controlo de velocidade | Caraterísticas “função de controlo da velocidade e de reinício da velocidade” |

Travagem DC | Frequência de arranque: 0,00 ~ Frequência máxima; Tempo de travagem: 0,0 ~ 100,0s |

Tempo de aceleração/desaceleração | 0.0s ~ 6500.0s |

Especificações de E/S

Entrada analógica | 1 canal (0~10V / 0~20mA) |

|---|---|

Saída analógica | 1 canal (0~10V / 0~20mA) |

Saída digital | 1 Saída de relé programável (TA, TC) |

Comunicação | RS-485 padrão (Modbus) |

Ambiente operacional

Local de instalação | No interior, sem luz solar direta, sem poeiras, gases corrosivos, etc. |

|---|---|

Altitude | Abaixo de 1000 metros |

Temperatura ambiente | -10°C a +40°C |

Humidade | <95%RH, sem condensação |

Dimensões estruturais

Dimensões (L x P x A) | 72 x 105 x 146 mm |

|---|---|

Tamanho da instalação (A x B) | 63,0 x 136,5 mm |

Furo de instalação | φ2.3 |

Garantia de qualidade

Este produto é desenvolvido e fabricado pela Nanjing Oulu Electric Corp, Ltd. Como uma empresa nacional de alta tecnologia centrada na automação industrial e nas novas energias, temos uma equipa de I&D experiente e instalações de produção avançadas, dedicadas a fornecer produtos e soluções fiáveis e de alta qualidade a clientes de todo o mundo.

Perguntas frequentes (FAQ)

- What is the main difference between the EV210 and EV510A series?The EV210 series is a miniature VFD, designed specifically for applications where installation space is extremely limited. This 2.2kW model is only 72mm wide. The EV510A is a high-performance general-purpose drive that is physically larger (the 1.5kW model is 112mm wide) and typically offers a more extensive set of I/O terminals (e.g., 7DI/2AI/2RO vs. the EV210’s 4DI/1AI/1RO).

- What does 150% torque at 0.25Hz mean for my application?This is a key feature of the EV210’s sensorless vector control (SVC). It means the drive can generate 1.5 times the motor’s rated torque when the motor is turning at only 0.25Hz (a near-standstill). This is critical for starting high-inertia loads (like a loaded conveyor or machine tool) smoothly and powerfully, without the motor stalling or the drive tripping on overcurrent.

- How do I select the right VFD model for my motor?Selection depends on your motor’s rated power, rated voltage, and application load type. In the model EV210-0022G-S2, “0022” indicates it’s for a 2.2kW motor, “G” stands for general-purpose load (suitable for constant torque applications like machine tools and conveyors), and “S2” signifies a single-phase 220V input. Always ensure the VFD’s rated output current (9.6A for this model) is greater than or equal to your motor’s nameplate rated current.

- Posso ligar este VFD a um PLC ou HMI?Yes. The EV210-0022G-S2 comes standard with a built-in RS-485 communication interface that supports the Modbus RTU protocol, allowing it to be easily integrated into a larger automation system for centralized control and monitoring.

Guia de início rápido (Como fazer)

Aviso: Os passos seguintes são apenas um guia básico. Todos os trabalhos eléctricos devem ser realizados por pessoal profissional qualificado. Antes de qualquer instalação eléctrica, certifique-se de que a alimentação principal está completamente desligada e aguarde pelo menos 10 minutos para que os condensadores internos do VFD se descarreguem completamente.

- Passo 1: InstalaçãoMount the inverter vertically on a sturdy, non-flammable surface, such as a metal mounting plate inside a control cabinet. Ensure there is sufficient clearance around the unit (at least 100mm recommended) for proper ventilation and heat dissipation.

- Passo 2: Cablagem do circuito principalConnect the Single Phase 220V AC power lines to the inverter’s input terminals R and S(L1). Connect the three wires of the three-phase asynchronous motor to the inverter’s output terminals U, V, and W. Securely connect the ground wire to the inverter’s PE (Protective Earth) terminal.

- Passo 3: Cablagem do circuito de controlo (para arranque/paragem básicos)Connect one end of an external switch (or button) to the digital input terminal X1. Connect the other end of the switch to the common terminal COM. Set parameter P0-02 (Command source selection) to “1” (Terminal command channel). Set parameter P4-00 (X1 function selection) to “1” (Forward run).

- Passo 4: Definição dos parâmetros do motor e regulação automáticaAquando da primeira ligação, introduza com precisão os seguintes parâmetros da placa de identificação do seu motor :

- P1-01: Motor Rated Power (set to 2.2kW)

- P1-02: Tensão nominal do motor (por exemplo, 220V)

- P1-03: Corrente nominal do motor

- P1-04: Frequência nominal do motor

- P1-05: Motor Rated Speed. For optimal vector control performance, perform a motor auto-tune. Set parameter P1-37 (Motor auto-tuning method) to “2” (dynamic auto-tuning) or “3” (static auto-tuning) and start the inverter.

- Etapa 5: Execução do testeAfter confirming all wiring and parameter settings are correct, turn on the main power. Close the external switch connected between X1 and COM. The motor should start rotating in the forward direction. Open the switch, and the motor will stop according to the set deceleration time.

Principais caraterísticas e vantagens

- Ultra-High Low-Speed Torque: Implements advanced sensorless vector control (SVC) to achieve 150% rated torque at just 0.25Hz, providing powerful and stable control for heavy-load startups like machine tools or loaded conveyors.

- Compact Miniature Design: With a width of only 72mm, this miniature VFD is one of the most compact 2.2kW drives on the market, saving critical installation space in control cabinets and OEM equipment.

- Robust Overload Capacity: Built for tough G-type (general purpose) loads, this 2.2kW VFD withstands 150% of rated current for 60 seconds and 180% of rated current for 3 seconds, handling demanding industrial cycles with ease.

- Integrated Automation Features: Includes a built-in PID controller for automating process control (like pumps and fans) and 16-segment multi-speed operation for complex programmed sequences.

- Flexible I/O & Communication: Standard on this single-phase 220V VFD are 4 digital inputs, 1 analog input (V/I selectable), 1 relay output, and built-in RS485 Modbus VFD communication for easy system integration.

- Optimized Motor Matching: Features a motor parameter self-learning (auto-tune) function (P1-37) to precisely match the drive’s advanced control algorithm to your specific asynchronous motor, maximizing torque and efficiency.

Ficheiro | Tamanho | Ação |

|---|---|---|

Guia de seleção de VFDs.pdf | 4.2MB | |

VFD EV210 Manual do utilizador.pdf | 1.3MB |