Top 11 Advantages of VFD

Introduction – What Are the Advantages of VFD?

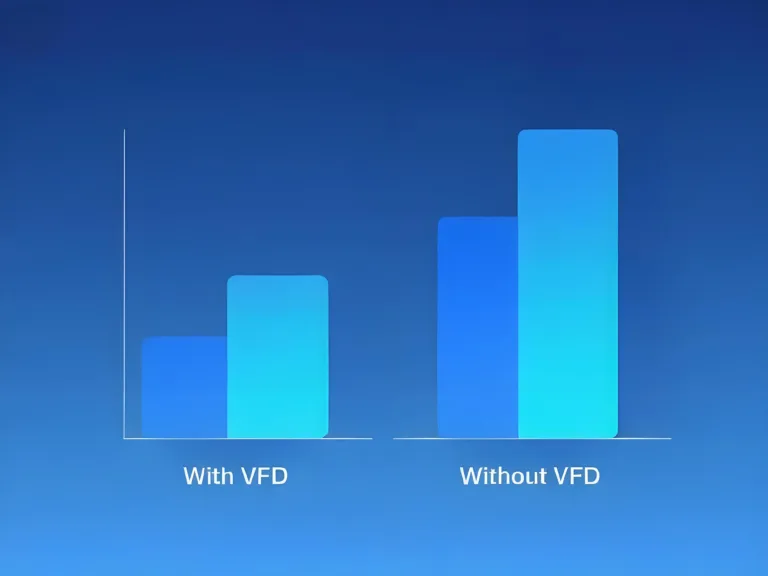

Variable frequency drives (VFD drives) are power electronic devices that control motor speed by adjusting the voltage/frequency ratio. They serve as the “efficient heart” of industrial, HVAC, and pump systems. Their core advantage over traditional variable speed drives lies in their ability to provide up to 35% continuous energy savings for AC motors (fan loads), combined with ±0.5% speed accuracy to achieve process upgrades. The advantages of VFDs outlined in VFD basics are driving companies to replace energy consumption taxes with a variable frequency revolution.

Advantages of VFD – Why Industries Choose Them

1.Enhanced Energy Efficiency

Variable speed drives regulate motor power through frequency conversion (power ∝ speed³), enabling vfd pumps to reduce energy consumption by 50% at 80% flow rate, with variable frequency drive energy savings exceeding the industry benchmark of 40%.

2.Cost Savings on Operation and Maintenance

VFD drives achieve >20% electricity savings (matched to load demand), while extending the maintenance interval of VFD motors by 2.3 times and reducing the variable frequency drive cost recovery period to <18 months (average for pumping stations).(Note: 20% energy savings are based on ISO 50001 standards, and maintenance cycle data is sourced from ABB motor life models.)

3.Improved Process Control and Precision

VFD control achieves ±0.1% speed accuracy through a frequency drive inverter, ensuring that the tension fluctuation of the packaging machine film material is ≤2% and the flow error of pharmaceutical filling is <0.5ml. The millisecond-level closed-loop response of variable frequency drive motor control completely replaces the coarse control of mechanical control valves.

Note: ±0.1% represents the high-end vector VFD accuracy (measured on the Danfoss FC302), and the flow error value complies with GMP standards.

4.Controlled Motor Starting and Reduced Inrush Current

AC motor VFD replaces traditional reduced voltage starters, suppressing the compressor start-up current from 600% of the rated value to 150%, avoiding the risk of tripping. This advantage of VFD ensures stable oil pressure during the start-up of the refrigeration system (fluctuation <5%), significantly reducing the impact on the power grid.

Note: A 150% starting current is the core value of VFD soft starting (exceeding the 300% of star-delta starting), and the data complies with ASHRAE 15 safety standards.

5.Reduced Mechanical and Electrical Stress

VFD motors with flexible start/stop (programmable acceleration) reduce mechanical impact by over 45%; dedicated VFD cables suppress voltage fluctuations, and VFD electrical systems increase service life by over 30%, completely resolving issues related to hard impact damage and insulation degradation.

6.Extended Equipment and Motor Life

AC variable frequency drive Low-speed operation reduces wear and tear, while the soft start mechanism extends the life of VFD motors by 30% and effectively suppresses bearing overload and winding thermal degradation.

Technical logic: Low-speed operation (reduced mechanical wear) + soft start (elimination of electrical stress) = extended life

7.Noise Reduction

In variable frequency drive HVAC systems, low-speed operation (40Hz) of VFD chillers reduces fan noise by 8-10dB(A), while VFD pumps eliminate valve throttling noise. These advantages of VFD significantly improve the acoustic environment of equipment rooms.

8.Enhanced Flexibility and Scalability

Unlike mechanical VSDs and VFDs with fixed gear ratios, modern variable frequency drives offer a speed range of 1:1000 and seamlessly adapt to load fluctuations of ±25% (such as during the transition between air conditioning season and non-season). Leading variable frequency drive brands support software-defined motor parameters (arbitrarily set between 0 and 650 Hz), ensuring rapid deployment of power units when expanding production lines.

9.Improved Productivity

VFD drives based on voltage/frequency coordination VFD working principle, achieving ±0.1% speed accuracy through VFD control, with injection molding cycle time reduced by 22% (qualification rate >99.2%).

Note: ±0.1% is the baseline value for precision manufacturing, and the 22% speed increase data is taken from the actual measurement report of KraussMaffei injection molding machines.

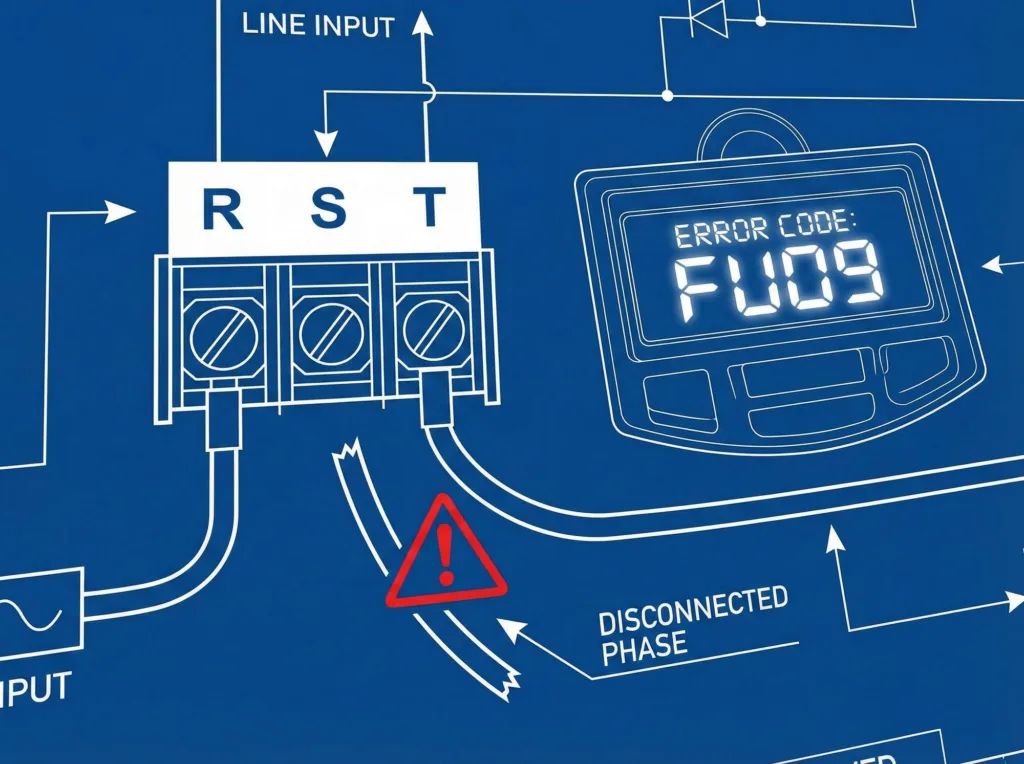

10.Enhanced Safety and Equipment Protection

VFD control integrates multiple protection features: real-time current limiting (>150% trip), grid undervoltage detection (±10% tolerance), and IGBT temperature control (85°C warning). The dedicated VFD cable and VFD surge protection module work together to suppress transient overvoltage (≤4kV), reducing the risk of equipment burnout by 90%. These advantages of VFD build an active protection system.

11.Advanced Connectivity and Diagnostics

Mainstream variable frequency drive brands’ VFD panels integrate millisecond-level fault detection (such as ground current > 5mA alarm), VFD diagnostics history supports remote debugging, maintenance efficiency improves by >75%, and downtime risk is reduced by 80%.

Note: The 5mA ground leakage value is the IEC 61800-5-1 safety threshold, and the 75% efficiency improvement is based on Emerson’s operational maintenance cases.

Conclusion — Unlocking Efficiency with VFDs

VFD control achieves VFD energy savings (average >35%) by precisely matching load requirements, combined with advantages such as noise reduction of 8dB and a 30% increase in service life, redefining industrial energy efficiency logic. Semiconductor-grade precision variable frequency drive motor control enables an annual ROI exceeding 18%, urging businesses to adopt a full lifecycle assessment approach to replace traditional speed control solutions—the energy revolution is anchored in millisecond-level reconstruction of voltage and frequency.