VFD No-Load Current Fluctuation (18–24 A): Causes & Fixes

VFD No-Load Current Fluctuation Case Background

During an on-site commissioning, we encountered a noticeable VFD No-Load Current Fluctuation issue:

- When a 30kW VFD was driving a 7.5kW motor, the no-load current was around 7A, with perfectly stable and balanced three-phase operation.

- However, with a 30kW motor, the no-load current fluctuated between 18A and 24A.

- After disabling the AVR function in VFD, the current dropped to 16A–18A with smaller fluctuations.

This is not a typical fault, but it is clearly abnormal. Below are five possible causes and optimization suggestions based on VFD troubleshooting practices.

1.Verify VFD motor autotuning Accuracy

In many variable frequency drive issues, incomplete or inaccurate motor autotuning is the root cause.

During VFD motor autotuning, the drive measures:

- Stator and rotor resistance & reactance

- Leakage inductance between stator and rotor

- IGBT switching characteristics (rise/fall times)

These precise parameters, often missing from the motor nameplate, are essential for high-accuracy inverter motor control. If autotuning is skipped or incorrect, high motor current at no-load and current fluctuations can easily occur.

2.Understand the Impact of AVR function in VFD

The Automatic Voltage Regulation (AVR) function stabilizes motor voltage through PWM control to maintain torque and speed, especially for heavy-load starts or large inertia applications.

However, under no-load or light-load conditions, when DC bus voltage variation is minimal, the AVR’s continuous adjustments may introduce voltage oscillations, leading to VFD No-Load Current Fluctuation.

Disabling AVR in such cases often stabilizes voltage and reduces current fluctuation.

3.Optimize Torque Boost in VFD parameter settings for motor

Torque boost (torque compensation) in VFD parameter settings for motor significantly affects no-load current stability:

- Overcompensation: Causes current surges at startup, even triggering overcurrent faults.

- Undercompensation: In heavy-load starts, torque may be insufficient to overcome load inertia, resulting in stalling or overcurrent trips.

Fine-tuning torque boost helps prevent VFD troubleshooting cases related to unstable no-load performance.

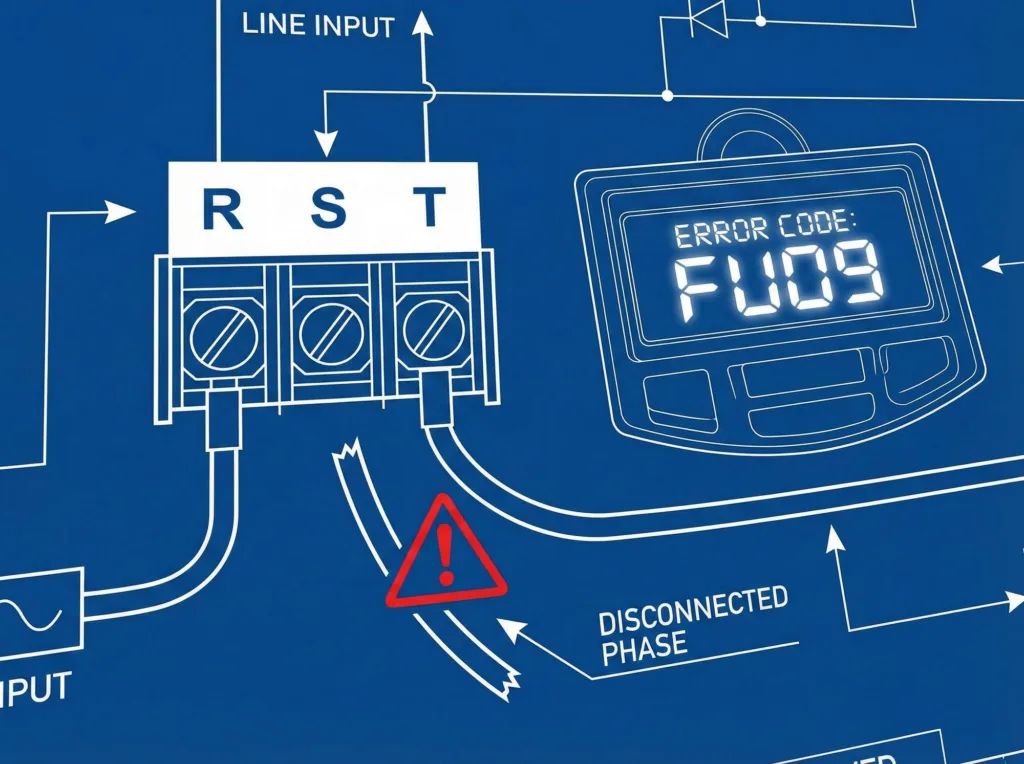

4.Check Three-Phase Input Power Quality

Many VFD Drives issues originate from poor input power quality. Confirm:

- Three-phase voltage balance

- Voltage stability under varying load conditions

Fluctuations in input voltage directly impact output voltage, which can cause VFD No-Load Current Fluctuation.

5.Compare with Direct Grid Operation

Test the motor under direct grid power (bypassing the VFD):

- If no-load current is below 18A (e.g., 10–15A) and stable, the motor is fine, and the issue lies in VFD settings.

- If the current still exceeds 18A with large fluctuations, the motor may have winding or insulation defects, requiring inspection or replacement.

Conclusion

The VFD No-Load Current Fluctuation in this case may be caused by incomplete VFD motor autotuning, unnecessary AVR adjustments at light load, improper torque boost settings, poor input voltage quality, or motor defects.

Addressing these factors by refining VFD parameter settings for motor, disabling or adjusting AVR function in VFD, and performing direct motor tests can effectively reduce current fluctuation and improve drive performance.