VFD Overcurrent Fault at 15–20 Hz: Fan Startup Case Study

Case Study: 250kW VFD with 220kW Fan Experiencing VFD Overcurrent Fault During Startup

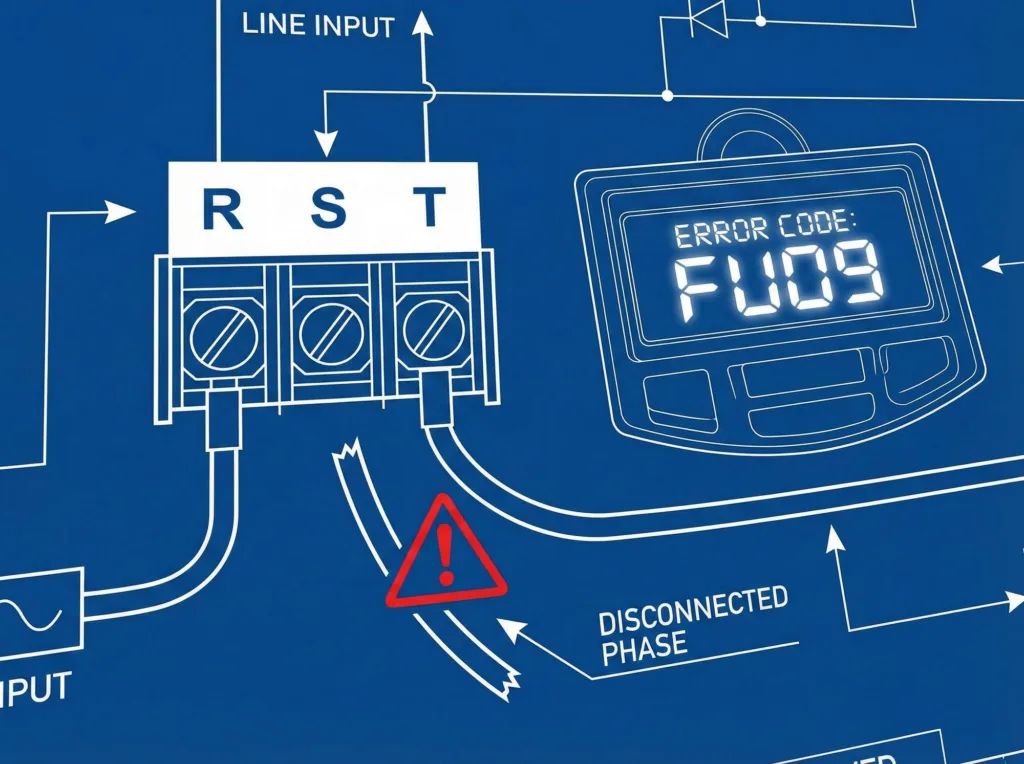

This real-world case involves a 250kW VFD driving a 220kW centrifugal fan. The issue occurs only during startup, specifically between 15Hz and 20Hz, where the current spikes to 500A, triggering a VFD acceleration overcurrent fault. Once the system passes this frequency range, it operates normally.

Such scenarios are not uncommon in vfd drives fan application and fan VFD tripping at low frequency cases. The root cause can be mechanical, electrical, or parameter-related. Below is a detailed breakdown of possible causes and solutions for engineers facing similar VFD Overcurrent Fault issues.

VFD Overcurrent Fault Cause Analysis

1.Inspect Mechanical Components and Ductwork

Begin with a mechanical inspection of the fan. Look for dust buildup, foreign objects, or loose ductwork. If the duct deforms during air intake or exhaust, pressure fluctuations can occur, causing large current variations.

From experience, severe current fluctuations (e.g., 80A–100A spikes) are often mechanical in origin—such as duct “breathing,” blade imbalance, or bearing wear. These must be resolved before addressing electrical adjustments.

2.Extend Acceleration Time to Reduce Low-Frequency Surges

If the acceleration time is too short, the motor ramps up too quickly, leading to high inrush currents in the 15Hz–20Hz range. This is a common cause of VFD Overcurrent Fault.

Increase the acceleration time from 50s to 150s and observe the results. This method is often recommended in how to fix VFD overcurrent fault guides.

3.Optimize Torque Boost and V/F Curve

In VF control mode, insufficient torque boost may prevent the motor from overcoming system resistance, while excessive boost can cause overcurrent during acceleration.

Adjust torque boost parameters appropriately, and select a V/F curve with higher startup torque. This is an effective measure for reducing VFD overcurrent fan start incidents.

4.Verify Motor and VFD Parameter Matching

Mismatched motor parameters—known as VFD motor parameter mismatch—can trigger premature protection. Ensure that the VFD settings match the motor nameplate exactly (rated current, pole pairs, power factor, etc.).

5.Adjust Overload Protection Thresholds

Most VFDs have factory overload protection set to 120% of rated current. For a 220kW fan with a rated current of ~440A, this limit may be too low for startup.

You can safely increase the threshold to 550A–600A, as long as it does not exceed 1.5 times the rated current (~660A). This helps bypass the startup surge without risking motor damage.

6.Use Skip Frequency to Avoid Problematic Range

If the issue only appears between 15Hz and 20Hz, enable the VFD skip frequency function. For example, set a skip frequency of 17Hz with a ±3Hz band, so the system jumps directly from 14Hz to 21Hz. This prevents fan VFD tripping at low frequency in that range.

7.Mitigate Long Cable Surge Current

In VFD long cable overcurrent cases, excessive cable length increases harmonics and peak voltage, which can cause surge currents.

Installing a VFD output reactor for long cables can suppress harmonics, reduce peak voltage, and minimize surge currents caused by cable capacitance charging/discharging.

Conclusion

This VFD Overcurrent Fault case is a system-level issue involving mechanical, ductwork, motor parameter, and VFD protection settings. By performing mechanical checks, extending acceleration time, optimizing torque boost, verifying parameters, adjusting overload thresholds, enabling skip frequency, and mitigating long cable effects, most variable frequency drive fan application overcurrent problems can be resolved.

Performing motor autotuning for fan applications at the commissioning stage and fine-tuning parameters for the site environment is one of the most effective ways to prevent these faults.