VFD Pump Selection Guide

By OULU Electric Engineering Team

Introduction

Stop throttling your pumps. We see it in mechanical rooms every day: a high-efficiency pump running at full speed, fighting against a partially closed valve to reduce flow. This is like driving your car with one foot on the gas and the other on the brake. It destroys equipment and burns money.

At OULU Electric, we engineer solutions, not just drives. Whether you are managing a municipal water station or a residential pool, the VFD Pump (Variable Frequency Drive Pump) is the only logical standard for modern fluid control. This guide explains exactly what it is, how to wire it using our EV210 Series, and why the ROI is undeniable.

What is a VFD Pump? (Meaning & Basics)

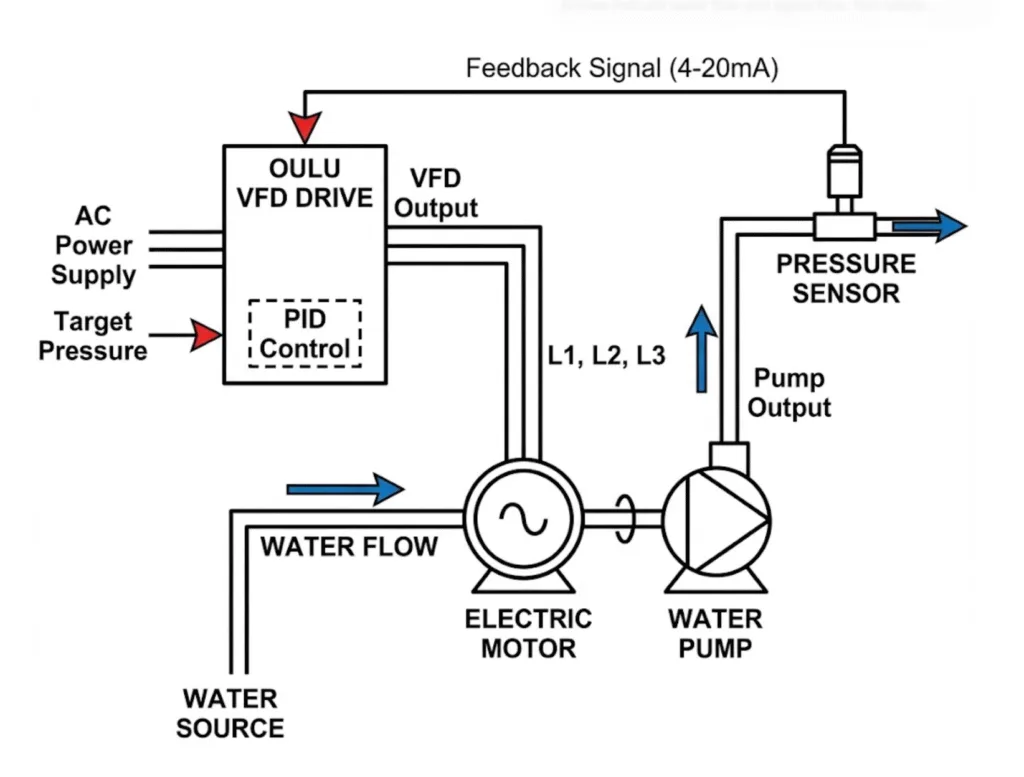

Let’s clarify the vfd pump meaning. A “VFD Pump” is not a specific, exotic type of machine. It is a system. It consists of three parts:

- The Pump & Motor: Standard centrifugal or submersible equipment.

- The Sensor: A pressure transducer (e.g., 4-20mA) or flow meter.

- The Drive (VFD): The brain that controls the motor speed.

The purpose of vfd in pumps is simple: match the motor speed to the actual demand. When you turn on a faucet, the drive speeds up. When you close it, the drive slows down or sleeps. No valves, no water hammer, no waste.

vfd pump full form

VFD stands for Variable Frequency Drive. In the pumping industry, you might also hear “VSD” (Variable Speed Drive) or “Inverter Pump.” They all refer to the same technology.

vfd pump working principle & Control Logic

How does a vfd pump system actually work?

It uses the physics of induction motors. The speed of your pump is directly tied to the electrical frequency (Hz) we supply. By changing the frequency, we change the RPM.

The Power of PID Control

Real control happens with PID (Proportional-Integral-Derivative). Take our OULU EV210 Series as an example. It is built specifically for this vfd pump control.

- You set a target pressure (e.g., 50 PSI).

- The pressure sensor sends real-time data to the VFD’s Analog Input (AI).

- The VFD compares the “Real” pressure with the “Target” pressure.

- If pressure drops, the EV210 instantly accelerates the motor. If pressure rises, it decelerates.

Technical Note: According to our EV210 User Manual, you can simply set parameter P0-00 to 6 to activate the specialized “Constant Pressure Water Supply Mode.” You don’t need a complex PLC; the drive does the math.

Key Applications: From Wells to Pools

We deploy vfd for pumps across every industry. Here is where they perform best.

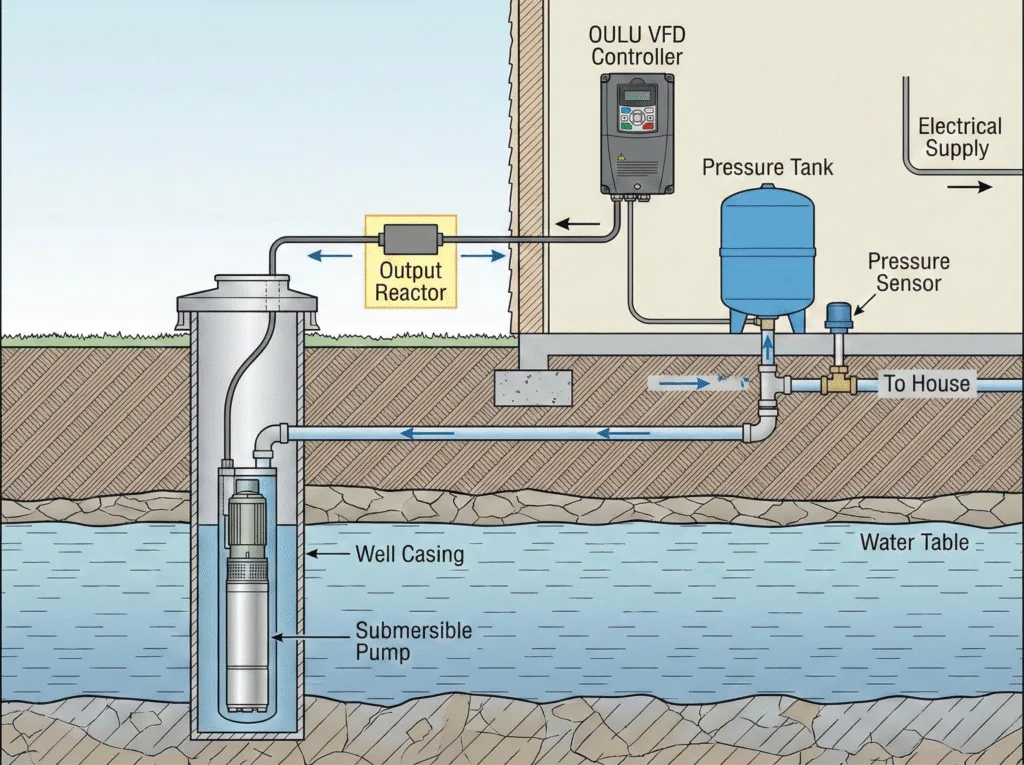

vfd well pump system (Constant Pressure)

Old well systems use a massive pressure tank and a “bang-bang” pressure switch (30/50 PSI). The shower pressure fluctuates constantly. A vfd constant pressure well pump system eliminates this. We use a tiny pressure tank (just for leak compensation) and an EV210 Drive. The result? Perfect, steady pressure regardless of how many taps are open.

vfd booster pump & Stations

For high-rise buildings, a vfd pump station is mandatory. We typically parallel two or three pumps. The VFD alternates the lead pump to ensure even wear (a feature standard in our EV210 macro settings). This setup handles morning peak hours and midnight low flows effortlessly.

vfd for submersible pump

Warning from our Engineers: Submersible pumps are tricky. The motor is hundreds of feet underground. The long cable acts as a capacitor. If your cable length exceeds 50 meters (160 feet), the high-frequency switching of the VFD can create “reflective waves” that double the voltage voltage at the motor terminals, burning the insulation.

- The Fix: You must install an Output Reactor between the VFD and the submersible pump. Do not skip this.

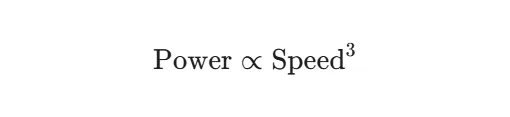

vfd pool pump Savings

Swimming pools do not need to run at 3450 RPM 24/7. That is overkill for filtration. By installing a vfd for swimming pool pumps, you can run the filtration cycle at half speed. According to Affinity Laws, running at half speed uses only 1/8th of the power. The savings are massive.

System Configuration: Panel & Wiring

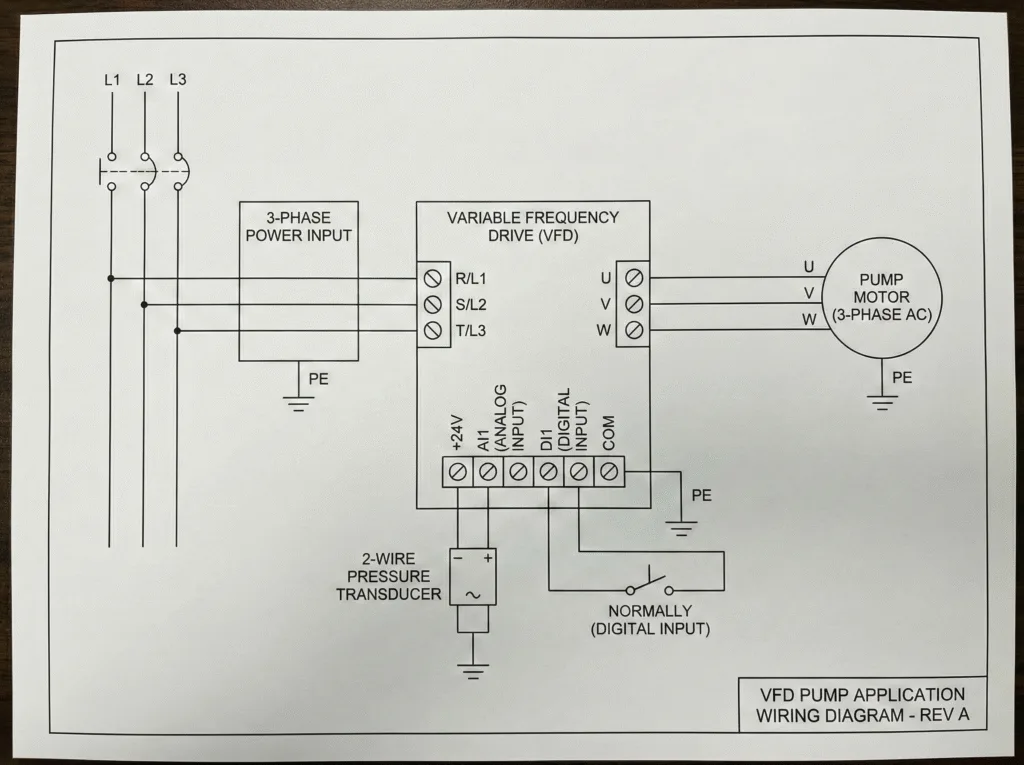

Building a vfd pump control panel requires attention to the I/O terminals.

Wiring a vfd pump control diagram

Referencing the OULU standard wiring:

- Power: Connect Grid (R/S/T) to Input, and Motor (U/V/W) to Output.

- Sensor: This is the critical part. For a 2-wire 4-20mA pressure transmitter:

- Connect the Sensor (+) to the VFD 24V terminal.

- Connect the Sensor (-) to the VFD AI (Analog Input) terminal.

- Bridge the VFD GND to the COM terminal if required by the specific model wiring diagram.

- Start/Stop: Wire a selector switch to Digital Input DI1 and COM.

The “Single Phase” Myth

We get asked about single phase pump vfd units daily.

- Clarification: Most industrial VFDs (including ours) take Single Phase Input but produce Three Phase Output.

- The Trap: You cannot run a standard residential capacitor-start single-phase motor with a standard VFD. The VFD will fault out. If you have a single-phase pump motor, you usually need to replace it with a three-phase motor to use a VFD, or buy a specialized (and expensive) single-phase output drive.

Why Invest? vfd pump price & ROI Calculation

The vfd pump price is higher than a simple magnetic starter. But looking at the price tag alone is amateur. You must look at the vfd pool pump savings and industrial energy reduction.

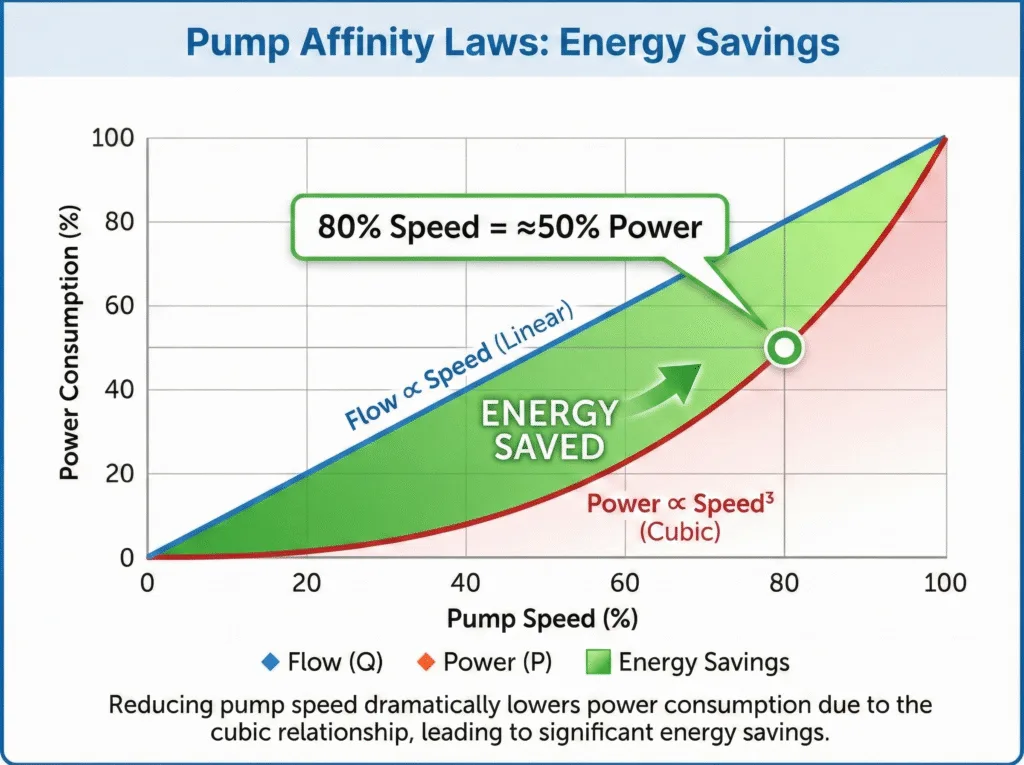

Calculating ROI with Affinity Laws

The physics are on your side. The Pump Affinity Laws state:

This means:

- 90% Speed = 73% Power consumption.

- 80% Speed = 51% Power consumption.

- 50% Speed = 12.5% Power consumption.

If you run a 10HP vfd chilled water pump and reduce the speed by just 10%, the VFD pays for itself in less than 12 months. Use a pump vfd calculator; the math never lies.

Understanding vfd well pump cost

The cost isn’t just the drive. A complete vfd well pump system includes the OULU Drive, a NEMA-rated enclosure (if outdoors), a pressure transducer, and a small expansion tank. While the upfront cost is double that of a pressure switch system, the constant pressure comfort and motor protection (soft start) justify the investment immediately.

Frequently Asked Questions (FAQ)

What is a VFD for a pump?

It is an electronic device that controls the speed of the pump motor. By adjusting the speed, it regulates water flow and pressure precisely, rather than wasting energy by throttling valves.

Can you put a VFD on any pump?

You can put a VFD on almost any pump driven by a three-phase AC induction motor.

- Centrifugal pumps: Excellent candidates.

- Positive displacement pumps: Good candidates (require constant torque drives like our G-Type).

- Single-phase pumps: Generally NO, unless you use a specialized drive.

Can you run a centrifugal pump on a VFD?

Yes, centrifugal pump with vfd is the ideal combination. Since centrifugal pumps follow the Affinity Laws, they offer the highest energy savings potential of any load type.

How to size a VFD for a pump?

Ignore the Horsepower (HP). Size the VFD based on the motor’s Full Load Amps (FLA). Check the motor nameplate. If the motor pulls 15 Amps, buy a VFD rated for at least 15 Amps (like our EV210-4T0075). For deep well pumps, we recommend upsizing by one level to handle thermal derating.

What size pump do I need for a 20000 gallon pool?

You need to turn over the water usually once every 8 hours.

A variable speed pump rated for 1.5 HP is usually sufficient, as you can run it at low RPM for filtration and ramp it up for cleaning.

What type of pump is best for well water?

A Submersible Pump is best for deep wells (over 25 feet). It pushes water up rather than pulling it, which is more efficient. Paired with a vfd well pump controller, it provides city-like water pressure.

Why vfd is used in pumps?

Energy Savings: Cuts power bills by 30-50%.

Process Control: Maintains exact pressure or flow.

Water Hammer Elimination: Soft start/stop prevents pipes from banging and bursting.

Equipment Life: Reduces mechanical stress on bearings and seals.

How does a vfd pump work?

It converts AC power to DC, then back to AC at a specific frequency. This variable frequency signals the motor to spin faster or slower, allowing the pump to meet the exact demand of the system at that moment.

How does vfd affect pump curve?

A pump curve shows Head vs. Flow at full speed. When you add a VFD, you create a “family” of curves. As you lower the speed, the entire curve shifts down and to the left. This allows the pump to operate efficiently at lower flow rates without generating excessive and damaging pressure.

Conclusion

A VFD Pump system is not a luxury; it is an engineering necessity. Whether you need the specialized sleep-wake functions of the OULU EV210 for a booster station or the raw efficiency of an EV510A for an industrial chiller, the technology is proven.

Stop wasting power. Start controlling your flow. Contact the OULU engineering team today for a quote on your system.