Why VFD IGBT Failure? Long Cables & Voltage Spikes Fix

Direct Answer: VFD IGBT Failure and capacitor failure are frequently caused by Voltage Spikes generated from Long Motor Cables (>50m). The reflected wave phenomenon can double the voltage, exceeding the IGBT’s 1200V rating. To fix this, you must install an Output Reactor and lower the Carrier Frequency immediately.

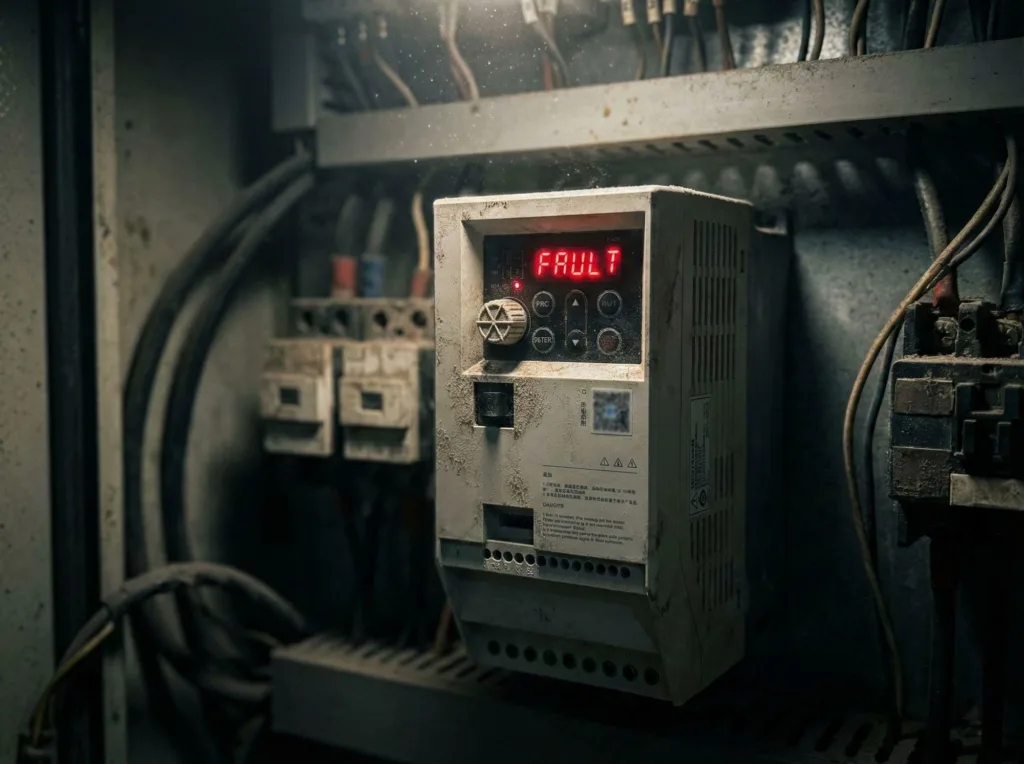

Today, we’re reviewing a classic “exploding drive” case from a coal mine site: A variable frequency drive (VFD) used for a winch experienced frequent breakdowns and explosions of its internal IGBT modules and DC bus capacitors. Multiple modules were replaced on-site, but each replacement unit failed immediately. Engineers were unable to identify the cause and were utterly frustrated.

This was absolutely not due to poor inverter quality. Instead, it stemmed from overlooking an invisible killer in industrial settings—the Long Cable Effect.

Why Do Long Motor Cables Cause VFD Failure?

In coal mines, deep well pumps, or large conveyor belt applications, the distance between the frequency converter and the motor often exceeds 50 meters, sometimes reaching over 100 meters.

This is the root cause of the problem.

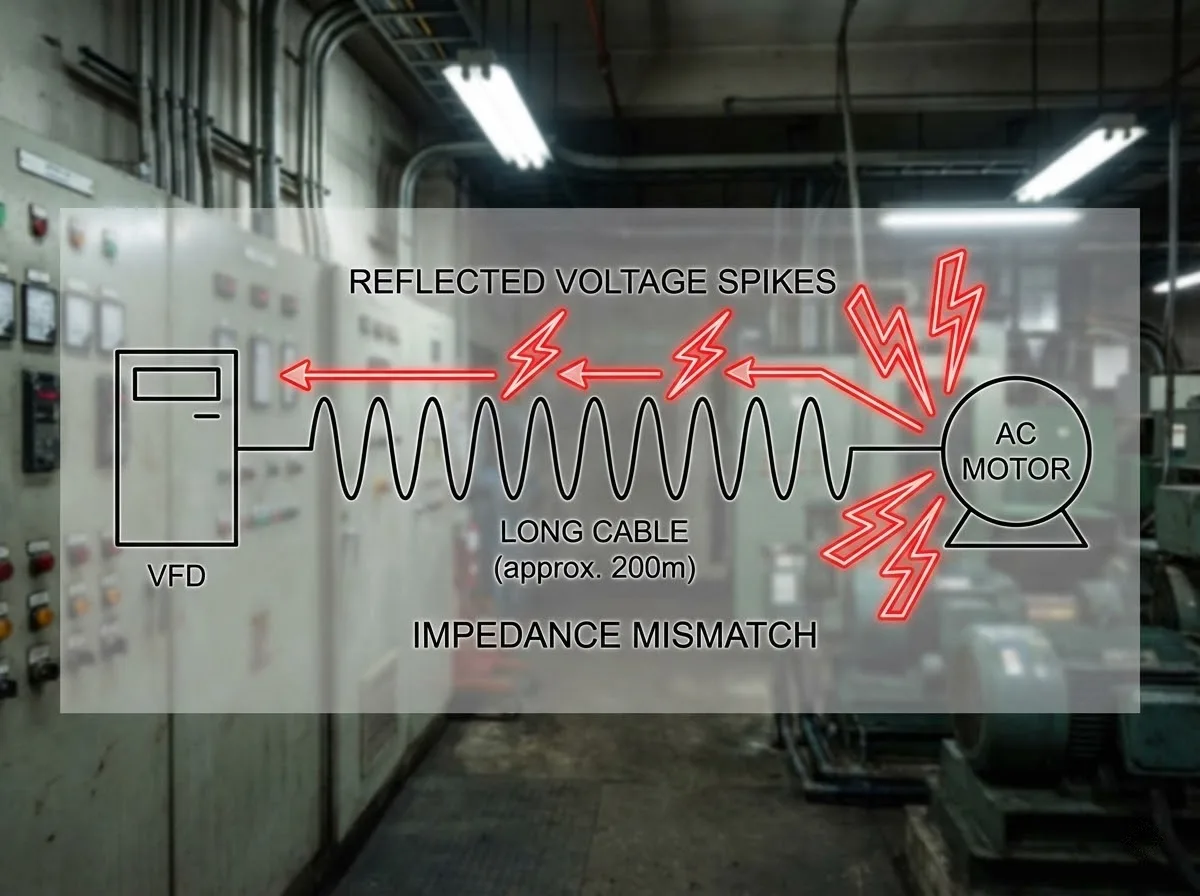

Once cable length exceeds 50 meters, distributed capacitance between cable phases becomes highly significant. During inverter operation, IGBTs perform high-frequency switching (PWM pulses), with each pulse generating harmonics in the cable.

These harmonics undergo superposition when propagating through long cables.

- Normal voltage: Peak voltage in a 380V system is approximately 540V.

- Superimposed spikes: At the end of a 100-meter cable, superimposed voltage spikes can easily reach 2000V – 2500V.

The Physics of Destruction: IGBT vs. Voltage Spikes

Why do these spikes blow up your VFD? Let’s examine a stark comparison:

Component | Standard Rating (380V Class) | Actual Surge Voltage (Long Cable) | Result |

|---|---|---|---|

IGBT Module | 1200V | 2000V – 2500V | Instant Breakdown |

DC Capacitor | 400V/450V (Series ~900V) | >1000V + High Frequency Heating | Explosion / Bulging |

When impedance mismatches occur at the motor end, these spike voltages as high as 2000V generate reflected waves that bounce back to the inverter unit like waves crashing against rocks.

Your IGBTs are rated for only 1200V. When confronted with a 2000V surge voltage, they will be instantly damaged. This is akin to using a paper shield to stop a bullet—VFD IGBT failure is the inevitable outcome.

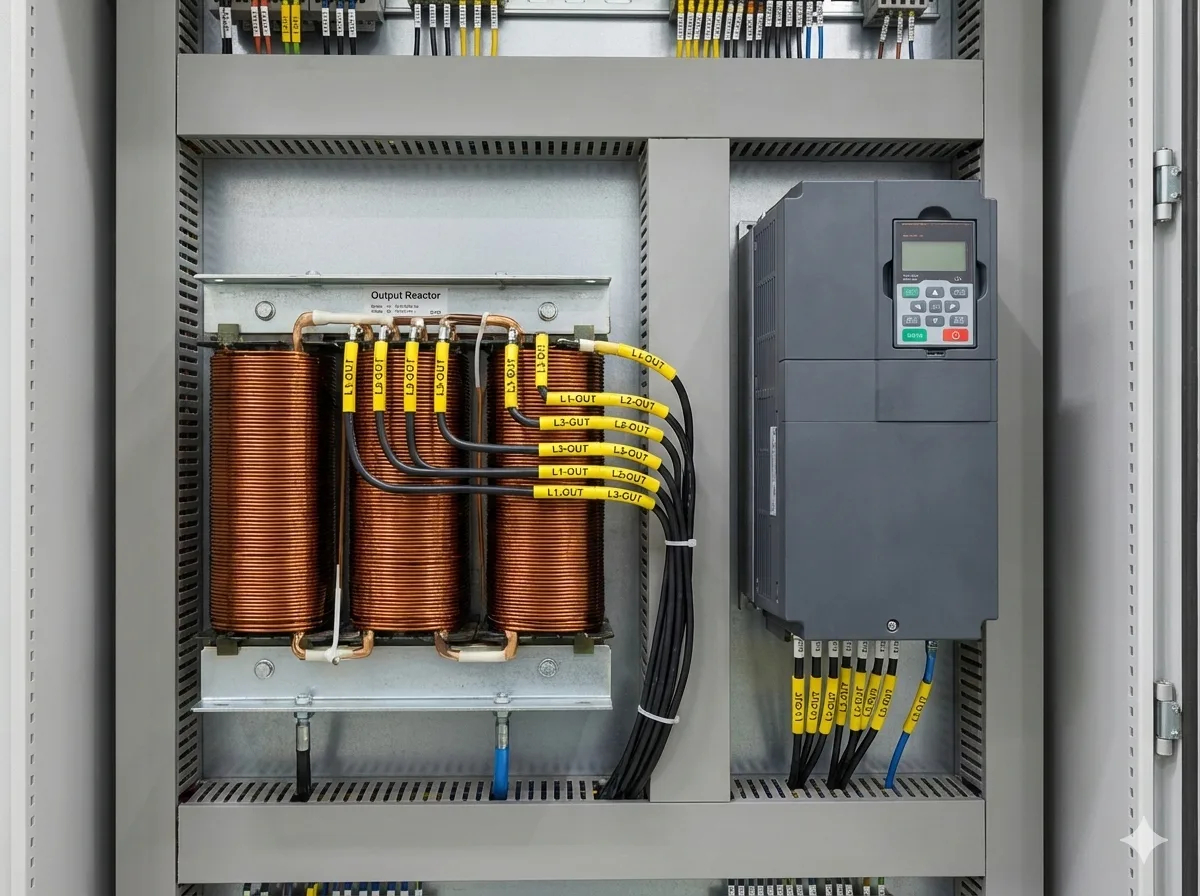

Solution 1: Install an Output Reactor (The Hardware Fix)

An Output Reactor must be installed between the output terminals (U/V/W) of the VFD and the motor cable.

The functions of the Output Reactor are:

- Capacitive Compensation: Counteracts the effects of distributed capacitance in long cables.

- Spike Suppression: Smooths the PWM output waveform, forcibly suppressing the amplitude of spike voltages.

- Insulation protection: Extends the lifespan of motor windings and VFD modules.

Refer to the Oulu VFD Selection Guide: For cable lengths exceeding 50 meters, the output reactor is standard equipment, not optional.

Solution 2: Lower the Carrier Frequency (The Software Fix)

If you don’t have a reactor on hand, you can extend its lifespan by adjusting parameters.

The Carrier Frequency determines how many times per second the IGBT switches. The higher the switching frequency, the denser the harmonic spikes generated.

- Procedure: Refer to the P0-15 (Carrier Frequency) parameter in the Oulu EV510A User Manual.

- Adjustment recommendation: Manually reduce the default 4kHz or 8kHz setting to 1.0kHz – 2.0kHz.

While lowering the carrier frequency may slightly increase motor noise, it significantly reduces IGBT switching losses and the probability of harmonic superposition, thereby decreasing the risk of VFD IGBT Failure.

FAQ: VFD Long Cable Issues

Q1: At what cable length do I need an output reactor?

It is generally recommended to install an output reactor when the motor cable length exceeds 50 meters (164 ft). If the length exceeds 100 meters, a sine wave filter is recommended.

Q2: Can I just buy a VFD with a higher voltage rating?

Theoretically possible (e.g., using a 690V inverter in a 380V system), but this is extremely costly and impractical. Installing an output reactor remains the most cost-effective solution.

Q3: Why did my capacitor explode, too?

Because the surge returning isn’t just high voltage, but also high-frequency pulse currents. This causes rapid internal heating (Overheating) in the electrolytic capacitor, ultimately leading to electrolyte expansion and casing rupture.

Q4: Does Oulu VFD EV510A protect against this?

Oulu EV510A features comprehensive overcurrent and overvoltage protection. However, physically reflected cable voltage (Reflected Voltage) is an external system design issue that requires the use of reactors for complete resolution.