Avoid These 8 VFD Long Cable Hazards: A Guide to Max Length

Hello everyone, today I’d like to share a very common yet easily overlooked issue encountered in the field: the hazards caused by excessively long VFD cables.

In variable frequency drive applications, if cable lengths exceed reasonable limits, they can trigger various VFD output problems and even lead to motor insulation failure, increasing maintenance difficulty and costs.

Based on my years of practical experience:

- Unshielded power cables generally won’t cause issues within 50 meters.

- Shielded power cables are typically safe within 30 meters.

- In real-world applications, unshielded cables should ideally be kept under 120 meters, while shielded cables are best limited to 50 meters.

This does not mean cables cannot exceed these lengths, but doing so increases susceptibility to various issues such as VFD cable harmonics, surge currents, and reflected waves. While solutions exist for 300m or 400m cables, they significantly increase costs and complexity.

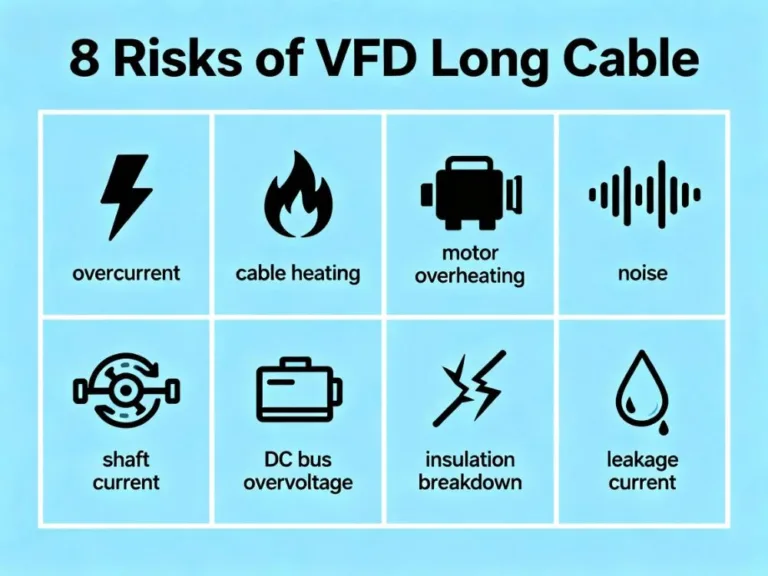

Eight Major Hazards of VFD Long Cable

1.Overcurrent Alarm During Startup

Excessively VFD long cable can cause surge currents during startup, triggering VFD overcurrent alarms. For example, a 15kW motor with a 150-meter cable may immediately report a fault during startup. This is a classic result of the combined effects of parasitic capacitance and spike voltage.

2.Severe Power Cable Heating

VFD Long cable carry substantial high-frequency harmonic currents (VFD cable harmonics), causing significant cable heating. This differs entirely from normal sinusoidal operation and is a side effect of PWM (Pulse Width Modulation) output.

3.Motor Overheating

Low-order harmonics from VFD long cable increase copper losses, while high-order harmonics increase iron losses. This leads to elevated overall motor temperature rise, ultimately accelerating the aging of VFD-rated motors.

4.Excessive Motor Noise

Reflected waves induce electromotive force within the motor, causing silicon steel laminations to vibrate and produce noticeable noise. This is also one of the common VFD output problems encountered in the field.

5.Shaft Voltage and Shaft Current

Harmonic voltages induced by VFD long cable can lead to VFD-induced shaft voltage and VFD shaft current, ultimately disrupting the bearing oil film and triggering motor bearing failure due to VFD. Bearings may fail within weeks or even days under severe conditions.

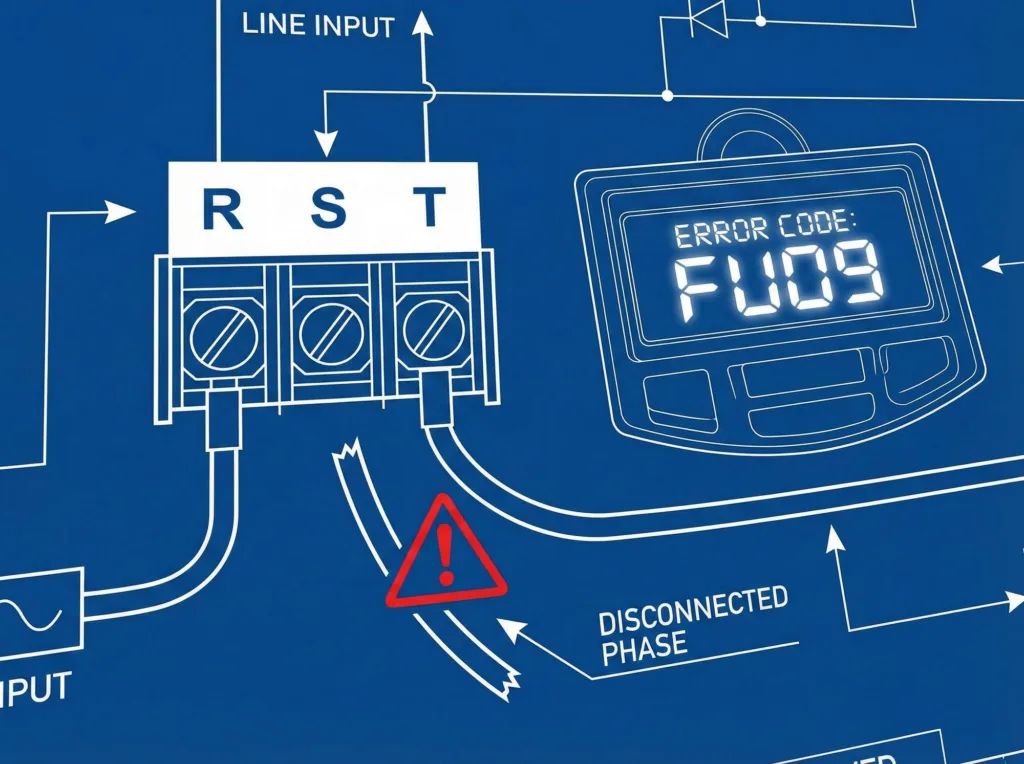

6.DC Bus Overvoltage

Voltage reflections from long cables feed back into the DC bus voltage, causing overvoltage. This issue is highly insidious and often misdiagnosed by engineers as a component failure during VFD fault diagnosis.

7.Motor Insulation Breakdown

When reflected waves from long VFD cables superimpose to form spike voltages, these can exceed 2000V—far surpassing the withstand voltage of standard industrial frequency motors (approximately 900V). This results in motor insulation failure, manifesting as ground faults or short circuits.

8.Excessive Leakage Current

Longer cables induce higher voltages on motors, causing leakage currents that may reach tens of amperes. This not only shortens motor lifespan but also triggers protective actions like VFD tripping due to overvoltage on long cables.

Conclusion

In summary, the eight major risks associated with VFD long cables include VFD overcurrent, VFD cable harmonics, shaft current, motor insulation failure, DC bus overvoltage, and others. If VFD trip causes are unclear on-site, particularly issues stemming from VFD overload, reflected waves, or common mode voltage, cable length is likely a contributing factor.

Therefore, during the variable frequency drive wiring design phase, it is essential to reasonably control the VFD maximum cable length and consider the shielded vs unshielded VFD cable length limit. If extremely long cables are unavoidable, compensation and optimization can be achieved through measures such as common mode chokes, output reactors, shielded cables, and motor derating.

Only by doing so can the 8 risks of VFD cable length exceeding the limit be avoided, ensuring long-term stable system operation.