3 Causes of PLC Module Failure & How VFD Harmonics Kill It

Today, let’s discuss the real culprit behind frequent PLC module failures.

I just got a call from an old acquaintance complaining that several PLC modules have burned out in recent months, with no clear cause found, leaving them overwhelmed. This is actually a common headache for frontline electrical engineers. Drawing on over 30 years of industry experience, I’ll break down the problem and provide a practical approach to resolving PLC module failures.

Throughout my career, systems under my direct supervision have never experienced module burnouts. Yet projects managed by my colleagues and trainees frequently suffer this issue. Through analysis, I’ve discovered that the core cause of PLC module failures is often overlooked.

The Invisible Killer: VFD Harmonics Cause PLC Module Failure

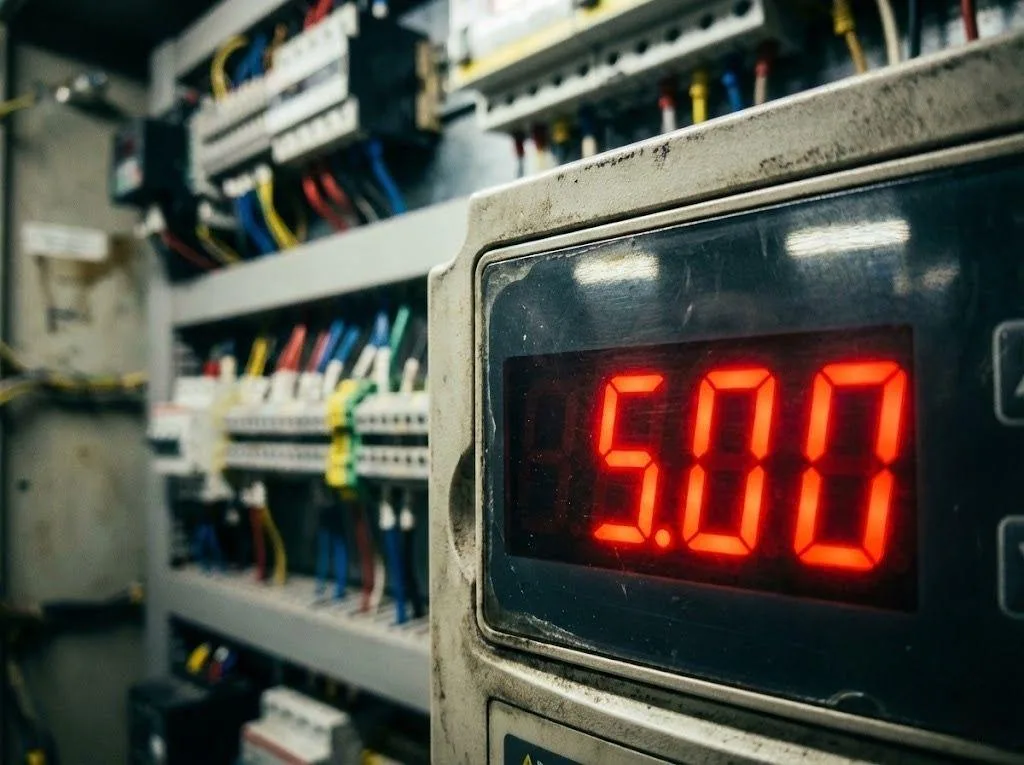

If your PLC power modules keep burning out, don’t just focus on the PLC itself. Look up at your power grid.

The culprit behind the vast majority of burnout incidents is the power supply grid. Inspect your site: are there numerous variable frequency drives (VFDs) or DC speed controllers installed? These devices are classic examples of nonlinear loads.

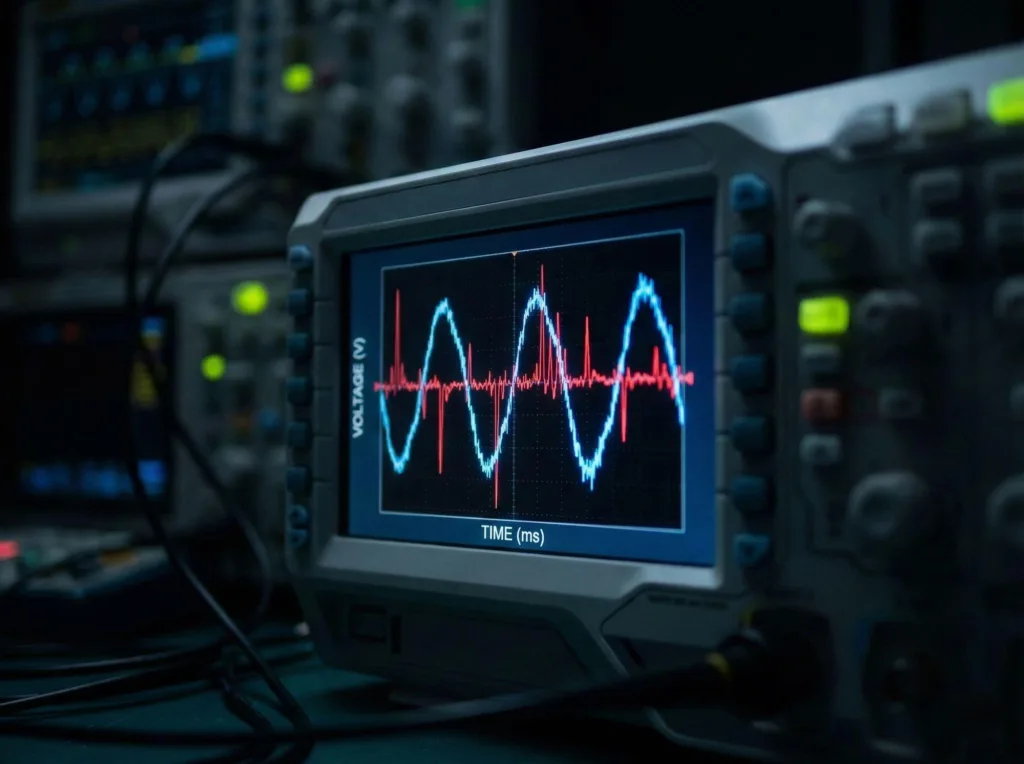

When numerous such devices exist in the grid, they generate devastating VFD harmonics. These harmonics accumulate within the grid, forming high-order harmonic voltages. When these distorted voltage waveforms impact the PLC power supply module, the excessively high voltage and extremely rapid frequency overwhelm the internal components, ultimately causing PLC module failure.

It’s like slowly poisoning someone by lacing their water with a slow-acting toxin—collapse is inevitable. If you don’t address the harmonic issue, PLC module failure will haunt your equipment like a recurring specter.

Cut the Noise: Strategies to Prevent PLC Module Failure

Now that we know the source of the problem, how do we fix it? We must take decisive action—either “block” or “prevent.”

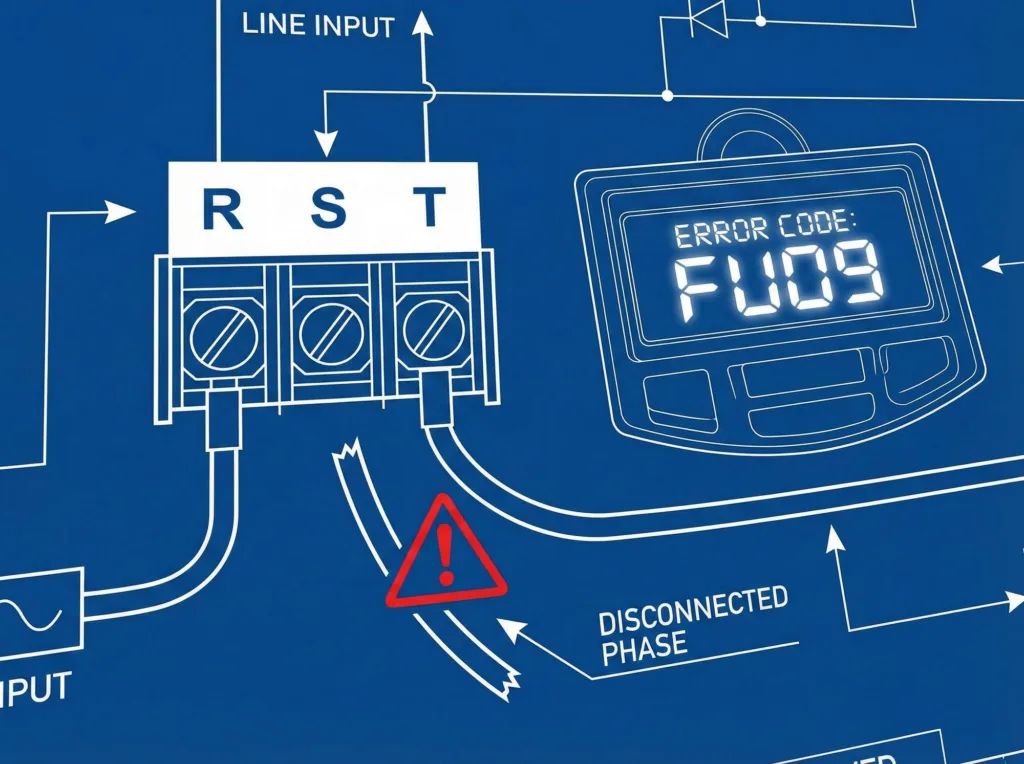

1. Source Blocking

The most effective approach is to install an Input Reactor at the input of all nonlinear loads (such as variable frequency drives). This forcibly suppresses harmonic feedback into the grid, fundamentally reducing the risk of PLC module failure.

Refer to our commonly used Oulu VFD EV510A User Manual. High-quality VFDs incorporate this consideration in their design. The EV510A series employs universal current vector control, and its manual explicitly states that proper peripheral equipment selection is critical in complex industrial environments. Using compliant drives significantly reduces interference to others.

2. Terminal Protection

If you cannot alter the grid environment, protect your PLC. Install a filter or input reactor at the PLC’s power input. This acts like a bulletproof vest for the PLC, weakening and suppressing Harmonic Interference from the grid. It absorbs the cyclic shocks, thereby preventing PLC Module Failure.

While reviewing the VFD Selection Guide.pdf, I also noted that Oulu’s selection guide specifically emphasizes environmental impacts on equipment (environmental temperature/humidity). Although this pertains to VFDs, the principle remains consistent: Power Quality is the lifeline for all industrial electronic equipment.

The 24V Power Supply Myth

Here I must correct a major misconception. Many non-professionals assume: “24V is just 24V—any old switching power supply will do.”

This is classic layman’s talk and another primary cause of PLC module failure.

The purity of the power supply directly determines system stability. Particularly in the VFD EV200 User Manual, we see strict definitions for control circuit terminals. If your 24V power comes from a cheap, low-quality power supply with massive ripple, or if this 24V line also powers high-power solenoid valves, then back EMF and ripple will equally destroy your PLC module.

To prevent PLC module failure, always use a dedicated, high-quality switching power supply for the PLC and strictly separate power circuits from control circuits.

Conclusion

Addressing PLC power supply hazards is far more complex than simply replacing a module. Ultimately, it requires combating Harmonic Interference within the power grid.

Whether installing reactors for nonlinear loads or selecting inherently robust drive equipment during the specification phase—such as the referenced Oulu EV510A—its optimized internal circuit design effectively minimizes grid pollution. As professional engineers, we must maintain a deep respect for power quality.

Don’t let substandard power supplies become the hidden killer of your control systems. Choosing the right solution is the only way to eliminate the nightmare of PLC module failures permanently.