EV210-0150G-T4: High-Torque Compact 3-Phase 380V VFD | 15kW, 20HP

Why Choose This 15kW (20HP) 380V 3-Phase VFD?

This specific 15kW 380V VFD is the premier choice for OEM machine builders and industrial applications where high torque and panel space are both non-negotiable.

Maximum Power Density: The EV210-0150G-T4 delivers a full 15kW (20HP) in a 118mm chassis. This is significantly smaller than the 150mm width of the general-purpose EV510A-0150G-T4, making it the clear choice for high-density control cabinets.

Superior Torque for Heavy Loads: This drive provides 150% torque at 0.25Hz. This superior low-speed performance is critical for reliably starting the heaviest constant-torque loads like industrial mixers, crushers, and large CNC spindles, outperforming standard drives rated at 0.5Hz.

Reliable & Cost-Effective Automation: With its focused I/O, built-in PID, and standard Modbus, this drive provides the essential features for smart, reliable control without the cost and footprint of a larger, more complex inverter.

Typical Application Fields

Heavy-Duty Grinders & Crushers

A perfect match for hard-starting, high-impact loads. Its 150% at 0.25Hz torque can handle the initial impact and high inertia of stone crushers, large industrial grinders, or chippers.

Large Machine Tools (CNC)

Ideal as a 20HP CNC spindle VFD or for main drives on heavy-duty lathes and milling machines running on a 380V system.

Industrial Mixers & Extruders

A great fit for constant-torque loads that demand high torque and robust overload protection to process thick or viscous materials like plastics, rubber, or food dough.

Control Characteristics

Control Mode | High-Performance Current Vector Control , Sensorless Vector Control (SVC), V/F Control |

|---|---|

Highest Frequency | Vector Control: 0~500Hz; V/F Control: 0~500Hz |

Carrier Frequency | 0.5KHz ~ 16.0KHz (Adjustable, for low noise operation) |

Speed Tracking | Features “speed tracking speed restart function” |

DC Braking | Start Frequency: 0.00 ~ Max Freq; Braking Time: 0.0 ~ 100.0s |

Accel/Decel Time | 0.0s ~ 6500.0s |

I/O Specifications

Analog Input | 1 channel (0~10V / 0~20mA) |

|---|---|

Analog Output | 1 channel (0~10V / 0~20mA) |

Digital Output | 1 Programmable Relay Output (TA, TC) |

Communication | Standard RS-485 (Modbus) |

Operating Environment

Installation Site | Indoors, no direct sunlight, no dust, corrosive gases, etc. |

|---|---|

Altitude | Below 1000 meters |

Ambient Temperature | -10°C to +40°C |

Humidity | <95%RH, no condensation |

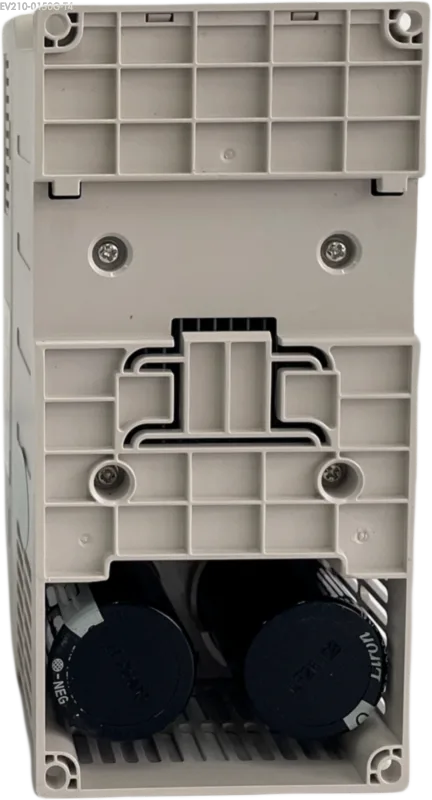

Structural Dimensions

Dimensions (W x D x H) | 118 x 154 x 241 mm |

|---|---|

Installation Size (A x B) | 106.0 x 229.0 mm |

Installation Hole | φ2.8 |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

What is the main difference between the EV210-0150G-T4 and the EV210-0022G-S2?

The key difference is the input power. The T4 model is for Three-Phase 380V industrial power. The S2 model is for Single-Phase 220V power, typically used to run 3-phase motors where only 220V single-phase is available.

How does this 15kW VFD compare to the EV510A-0150G-T4?

The EV210 is the specialist for compact spaces and low-speed torque. It is significantly narrower (118mm wide) than the 150mm EV510A and offers superior starting torque (150% at 0.25Hz) compared to the EV510A’s 0.5Hz. The EV510A offers more I/O terminals (7 DI vs 4 DI) for more complex general-purpose applications.

What is the output current of the EV210-0150G-T4?

The rated output current for this model is 32.0 Amps, designed to match a 15kW (20HP) 380V motor.

Can I use this VFD for a hard-starting load like a crusher or large mixer?

Yes. This drive is ideal for such applications. Its advanced sensorless vector control produces 150% of the motor’s rated torque at just 0.25Hz (a near-standstill), providing the power needed to start high-inertia loads smoothly.

Quick Start Guide (How-To)

Warning: The following steps are a basic guide only. All electrical work must be performed by qualified professional personnel. Before any wiring, ensure the main power is completely disconnected and wait at least 10 minutes for the internal capacitors of the VFD to fully discharge.

Step 1: Installation

Mount the inverter vertically on a sturdy, non-flammable surface, such as a metal mounting plate inside a control cabinet. Ensure there is sufficient clearance (at least 100mm) for ventilation. This drive’s 118mm width allows for compact industrial installations.

Step 2: Main Circuit Wiring

Connect the Three-Phase 380V AC power lines to the inverter’s input terminals R, S, and T (L1, L2, L3). Connect the three wires of the three-phase asynchronous motor to the inverter’s output terminals U, V, and W. Securely connect the ground wire to the inverter’s PE (Protective Earth) terminal.

Step 3: Control Circuit Wiring (for Basic Start/Stop)

Connect one end of an external switch (or button) to the digital input terminal X1. Connect the other end of the switch to the common terminal COM. Set parameter P0-02 (Command source selection) to “1” (Terminal command channel). Set parameter P4-00 (X1 function selection) to “1” (Forward run).

Step 4: Motor Parameter Setting & Auto-tuning

Upon first power-up, accurately enter the following parameters from your motor’s nameplate :

P1-01: Motor Rated Power (set to 15kW)

P1-02: Motor Rated Voltage (set to 380V)

P1-03: Motor Rated Current (use your motor’s value)

P1-04: Motor Rated Frequency

P1-05: Motor Rated Speed. For optimal vector control performance, perform a motor auto-tune. Set parameter P1-37 (Motor auto-tuning method) to “2” (dynamic) or “3” (static) and start the inverter.

Step 5: Test Run

After confirming all settings, turn on the main power. Close the external switch (X1 to COM). The motor should start. Open the switch, and the motor will stop.

Core Features & Advantages

Unmatched Low-Speed Torque: Implements advanced sensorless vector control (SVC) to generate 150% rated torque at an ultra-low 0.25Hz. This ensures reliable startups for the most demanding high-inertia loads (like crushers or large industrial mixers).

Maximum Power in a Compact Frame: Delivers a full 15kW (20HP) of vector power from a compact 118mm-wide industrial housing, offering the highest power density in its class and saving critical panel space.

Heavy-Duty 15kW Overload Capacity: Built for G-type loads, this 15kW 380V VFD endures 150% of its 32.0A rated current for 60 seconds and 180% for 3 seconds, handling severe industrial cycles.

Built-in Process Control: Features an integrated PID controller for standalone automation of pressure, flow, or tension loops, plus 16-segment multi-speed control for programmed sequences.

Essential Industrial Connectivity: Standard with 4 digital inputs, 1 analog input (V/I selectable), 1 relay output, and RS-485 Modbus for straightforward integration into existing automation systems.

Motor Parameter Auto-Tuning: A dedicated self-learning function (P1-37) accurately measures motor parameters to optimize the vector control algorithm for your specific 15kW motor.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV210 User Manual.pdf | 1.3MB |