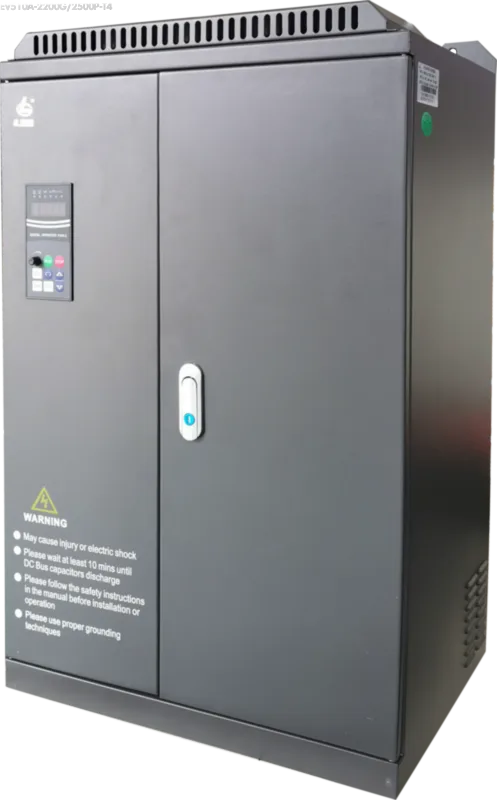

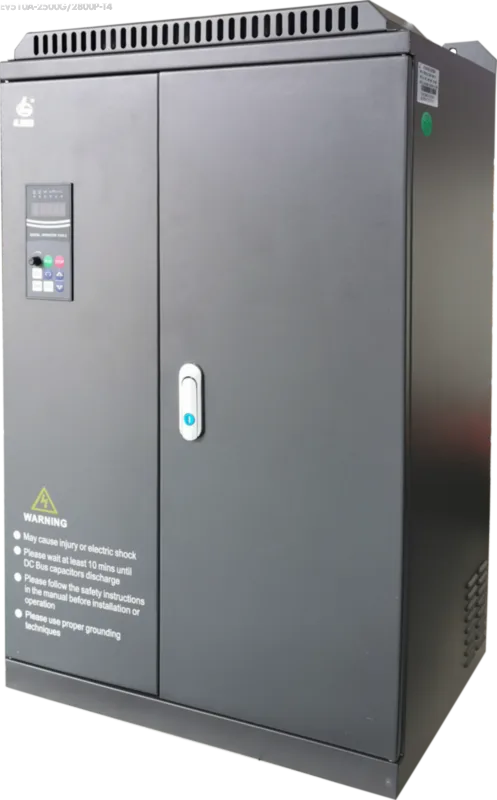

EV510A-2200G/2500P-T4 | 220kW(300HP) / 250kW(350HP) 380V Dual Rated Vector VFD

Parameter | G-Type: 0037G | P-Type: 0055P |

|---|---|---|

Motor Power | 3.7 kW / 5 HP (Constant Torque) | 5.5 kW / 7.5 HP (Variable Torque) |

Output Current | 9.0 A | 9.0 A |

Rated Input Current | 10.5 A | 10.5 A |

Power Capacity | 5.9 kVA | 5.9 kVA |

Input Power | Three-Phase 380V (±15%) | Three-Phase 380V (±15%) |

EV510A-2200G/2500P-T4: A High-Capacity VFD for Power, Precision, and Reliability

The EV510A-2200G/2500P-T4 is a high-performance vector Variable Frequency Drive (VFD) engineered to meet diverse and demanding applications in industrial automation. The defining advantage of this AC drive is its G/P Dual-Rated capability, which allows a single unit to be expertly configured for two different operational modes :

- G-Type (Constant Torque): Rated for 220kW (approx. 300 HP) “General” (G-type) loads, such as plastic extruders, rock crushers, or heavy-duty conveyors. This mode is defined by its high starting torque and robust overload capacity.

- P-Type (Variable Torque): Rated for 250kW (approx. 350 HP) “Pump or fans” (P-type) loads. This mode is optimized for energy efficiency in applications like centrifugal pumps and large-scale ventilation.

This intelligent dual-rating streamlines inventory for system integrators and provides a standardized, high-performance control platform. As an enhanced version of the EV510 series, the EV510A is “smaller in size, more compact in structure… and more stable in performance”. It utilizes a “high-performance current vector control” algorithm for outstanding precision and integrates essential reliability features like “Instantaneous stop not stop” (power loss ride-through) and a “Quick current-limit function” to maximize system uptime.

Why Choose the EV510A-2200G/2500P-T4?

In the 220-250kW power class, the EV510A-2200G/2500P-T4 provides an intelligent combination of power, precision, and value.

- Strategic Power Flexibility (Dual-Rated): The G/P dual-rating is this drive’s most intelligent feature. It eliminates the need to source and stock two separate AC drives for a 220kW heavy-duty machine and a 250kW fan. The EV510A-2200G/2500P-T4 handles both, reducing inventory costs and simplifying procurement.

- Engineered for Extreme Uptime: For critical processes, reliability is paramount. The “Instantaneous stop not stop” function provides essential ride-through for brief power sags, while the “Quick Current-limit” actively prevents nuisance trips from load shocks, keeping your operation running.

- A Compact High-Power Solution: As the upgraded EV510A version, this drive is “smaller in size, more compact in structure, and more stable in performance”. This saves valuable cabinet real estate and contributes to a lower Total Cost of Ownership (TCO) through enhanced reliability.

- Integrated Intelligence: This is more than a simple motor spinner. With powerful Sensorless Vector Control (SVC) for high-torque tasks and a “Built-in PID” controller for process loops, this single drive can manage a wide range of sophisticated automation tasks without needing an external PLC.

Typical Application Fields

Large Industrial Fans

Perfect for 350 HP large industrial fans, blowers, and HVAC systems. The built-in PID reads duct pressure to precisely match fan speed to building demand, dramatically reducing energy consumption.

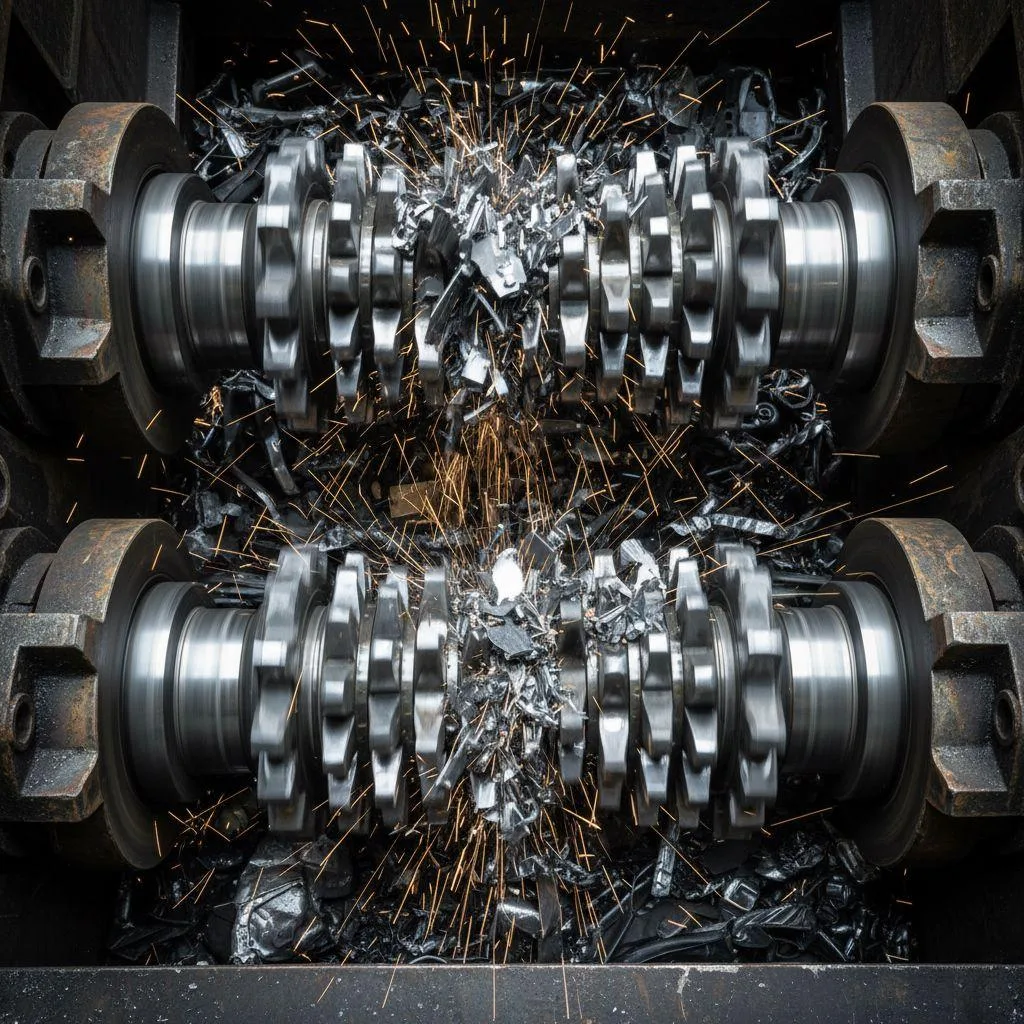

Industrial Shredders

The 300 HP G-Type rating delivers the extreme torque and 150% overload capacity required for industrial shredders to process tough materials like plastic, wood, or metal scrap.

Wastewater Aeration Blowers

Powers 250kW (350 HP) aeration blowers. The P-Type mode offers significant energy savings, while the PID control can be used to maintain precise dissolved oxygen levels in the treatment basins.

Control Characteristics

Parameter | G-Type: 2200G | P-Type:2500P |

|---|---|---|

Control Mode | V/F Control, Open-loop Vector (SVC), Closed-loop Vector (FVC) | V/F Control, Open-loop Vector (SVC), Closed-loop Vector (FVC) |

Overload Capacity | 150% Rated Current 60s; 180% Rated Current 3s | 120% Rated Current 60s; 150% Rated Current 3s |

Starting Torque (SVC) | 0.5Hz / 150% | 0.5Hz / 100% |

Speed Range (FVC) | 1:1000 | 1:1000 |

Steady Speed Precision (FVC) | ±0.02% | ±0.02% |

Digital Inputs (DI) | 7 channels (1 @ 100kHz) | 7 channels (1 @ 100kHz) |

Analog Inputs (AI) | 2 channels (AI1: 0-10V, AI2: 0-10V/0-20mA) | 2 channels (AI1: 0-10V, AI2: 0-10V/0-20mA) |

Structural Dimensions

Dimensions (W x D x H) | 520 x 382 x 835 mm |

|---|---|

Installation Size (A x B) | 400 x 810 mm |

Installation Hole | φ13 |

Weight | 107 kg |

Quality Assurance

This product is developed and manufactured by Nanjing Oulu Electric Corp., Ltd. As a national high-tech enterprise focusing on industrial automation and new energy, we have an experienced R&D team and advanced production facilities, dedicated to providing high-quality, reliable products and solutions to customers worldwide.

Frequently Asked Questions (FAQ)

Q: What is the G/P Dual-Rating on the EV510A-2200G/2500P-T4?

A: This specifies the drive’s dual-rating, selectable via parameter P9-76. G-Type (General) is rated for 220kW Constant Torque applications (like extruders) and provides a high overload capacity (150% for 60s). P-Type (Pump) is rated for 250kW Variable Torque applications (like fans) with a standard overload (120% for 60s).

Q: Is the EV510A an upgrade from the EV510?

A: Yes, the EV510A is the upgraded version. It is “smaller in size, more compact in structure, and more stable in performance”.

Q: What is “Instantaneous stop not stop”?

A: This is a power loss ride-through function. If the power sags, the drive uses the motor’s feedback energy to “compensate for voltage-drop to keep running for a short time,” preventing a shutdown.

Q: Can this VFD control two different motors?

A: Yes, but not simultaneously. It has a “Multi-motor Switch” function. You can program two motor profiles (in parameter groups P1 and A2) and switch between them using a digital input or parameter P0-24.

Q: What are the most common fault codes?

A: Common VFD fault codes include FU02 (Over current during acceleration), FU06 (Overvoltage during deceleration), FU09 (Under voltage), and FU14 (Inverter Overheat).

Q: Does this drive have a built-in PID controller?

A: Yes, it features a powerful “Built-in PID” controller. This allows it to receive an analog feedback signal (like a pressure or temperature sensor) and automatically manage a closed-loop process. The parameters are in a group PA.

Quick Start Guide (How-To)

This guide is intended to help you quickly set up and diagnose the EV510A Variable Frequency Drive based on the user manual.

Guide 1: Commissioning – How to Auto-Tune the Motor

To achieve the best performance in Sensorless Vector Control (SVC) mode (when P0-01=0), you must first perform a motor auto-tune.

- Input Motor Nameplate Data: In parameter group P1, enter the following values from your motor’s nameplate:

- P1-01: Motor 1 Rated power (kW)

- P1-02: Motor 1 Rated voltage (V)

- P1-03: Motor 1 Rated current (A)

- P1-04: Motor 1 Rated frequency (Hz)

- P1-05: Motor 1 Rated speed (rpm)

- Select Auto-Tune Mode: Set parameter P1-37 to choose the tuning type:

- 1: Asynchronous machine static self-learning

- 2: Asynchronous machine dynamic complete self-learning (Requires motor to be uncoupled)

- Execute Auto-Tune: After selecting the mode, press the RUN key to begin the auto-tuning process.

Guide 2: Process Control – How to Set Up PID

Using the built-in PID (Group PA) allows you to create a constant pressure pump system without an external PLC.

- Set PID Feedback Source: Wire your 4-20mA pressure transducer to analog input AI2. Set the AI2 jumper on the control board to ‘I’ (current). Then, set parameter PA-02 = 1 (PID feedback source = AI2).

- Set PID Target Value (Setpoint): Set PA-00 = 0 (PID reference source = PA-01). Then, enter your target pressure percentage in PA-01 (e.g., 50.0%).

- Adjust PID Gains:

- PA-05 (Proportional Gain Kp1): Default is 20.0. Adjust to speed up or slow down the response.

- PA-06 (Integral Time Ti1): Default is 2.00s. Adjust to eliminate steady-state error.

- Set Feedback Loss Detection: To prevent the pump from running at max speed if the sensor wire breaks, set PID feedback loss detection.

- PA-26: Set detection level (e.g., 10.0%).

- PA-27: Set detection time (e.g., 2.0s). This will trigger fault FU31 (PID feedback lost).

Core Features & Advantages

The design of the EV510A-2200G/2500P-T4 combines advanced control technology, robust protection, and versatile I/O, with all specifications sourced directly from the official technical manuals.

Unmatched Reliability & Uptime

- Instantaneous Stop Not Stop (Ride-Through): A critical reliability function. During a momentary power loss, the drive uses the motor’s regenerative energy to “compensate for voltage drop to keep running for a short time,” preventing a costly shutdown.

- Quick Current-limit Function: Automatically “Reduce overcurrent error on max extent” to protect the inverter from sudden load shocks and minimise overcurrent faults, ensuring continuous operation.

- Heavy-Duty Overload Capacity: Provides optimised overload protection for both G-Type and P-Type loads :

- G-Type (220kW): 150% of rated current for 60 seconds; 180% for 3 seconds.

- P-Type (250kW): 120% of rated current for 60 seconds; 150% for 3 seconds.

Advanced Control & Vector Performance

- Versatile Control Modes: Supports V/F control, Sensorless Vector Control (SVC), and high-precision Closed-loop vector control (FVC) with an optional PG card.

- Exceptional Starting Torque: The advanced vector algorithm delivers powerful torque output at low frequencies.

- G-Type (SVC): Achieves 150% of rated torque at just 0.5Hz.

- G-Type (FVC): Achieves 180% of rated torque at 0Hz.

- P-Type (SVC): Achieves 100% of rated torque at 0.5Hz.

- High Control Accuracy: In Closed-loop vector control (FVC) mode, the speed range reaches 1:1000 with a steady-speed precision of ±0.02%. In Open-loop vector control (SVC) mode, the speed range is 1:100 with a precision of ±0.5%.

- Wide Output Frequency: Supports an output frequency range of 0~500Hz in both vector and V/F control modes.

Flexible & Comprehensive Integration

- Comprehensive I/O: Features a full suite of programmable I/O for complex automation.

- 7 programmable Digital Inputs (DI): one of which supports up to 100KHz high-speed pulse input.

- 2 programmable Analog Inputs (AI): AI1 (0~10V) and AI2 (0~10V or 0~20mA).

- 2 Relay Outputs: (TA/TB/TC and RA/RC).

- 2 programmable Analogue Outputs (AO): Both support 0~20mA or 0~10V output.

- Multi-Motor Switching: Capable of storing two independent motor parameter sets (in groups P1 and A2) and switching between them via a digital input, allowing one VFD to control two different motors.

- Built-in PID Controller: Includes a full-featured PID controller (Group PA) to “realise process control closed-loop system conveniently,” perfect for managing constant pressure or flow without an external PLC.

- Standard Communications: Equipped with RS-485 (Modbus) and supports CAN link buses for easy system integration.

File | Size | Action |

|---|---|---|

VFD Selection Guide.pdf | 4.2MB | |

VFD EV510A User Manual.pdf | 1.8MB |