4 Key Differences Between Vector Control and Torque Control

Hello everyone, today we’ll discuss two key control strategies for variable frequency drives (VFDs): vector control and torque control. These represent the most fundamental control methods in VFD drives and are often referred to as high-performance VFD control methods.

Many people confuse their relationship: one is a control technique, while the other is a control mode. Simply put, vector control is a control method, whereas torque control is a control objective or operating mode. Next, we will delve into the distinctions and connections between the two.

Conceptual Differences

Within VFD control methods, vector control is primarily used for speed closed-loop control, while torque control is employed for constant torque output control.

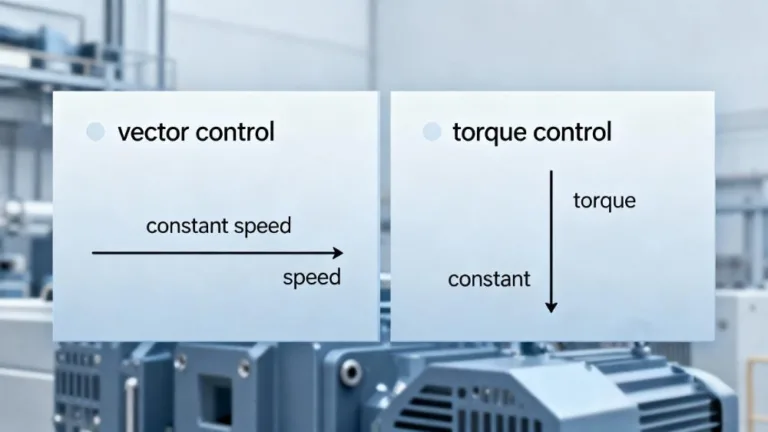

Assuming the VFD is currently operating in vector control mode, its input is a speed reference. The system’s objective is to maintain high-precision alignment between the output speed and the set frequency—that is, constant speed control.

When the VFD operates in torque control mode, its input signal is the torque reference.

For example: 0V corresponds to 0N·m, 10V corresponds to 200N·m, and when the reference is 5V, the output is 100N·m. Here, the system’s objective is to deliver stable torque output.

In summary:

- The control objective of vector control is speed stability

- The control objective of torque control is constant torque

Their control logics differ, yet their underlying algorithms are closely related.

Working Principle of Vector Control

The core concept of vector control (also known as flux vector control or field orientation control, FOC) is to emulate the control principle of a DC motor (DC motor analogy).

In DC motors, two key magnetic fields exist:

- The field magnetizing flux (provides magnetic flux)

- The armature field (generates torque)

In vector control for VFD drives, the control system decomposes the asynchronous motor’s current into two components:

- Magnetizing current component: Responsible for establishing magnetic flux

- Torque-producing current component: responsible for generating torque

This field-oriented control enables the asynchronous motor to behave like a DC motor, achieving high-precision speed regulation and dynamic response.

Common applications include: cranes, elevators, CNC machines, and scenarios demanding extremely high speed regulation.

In these applications, vector control achieves rapid and stable speed regulation through PID controllers while effectively minimizing errors caused by slip control.

Control Logic of Torque Control

Torque control is a mode based on torque output, commonly used in constant-tension scenarios such as rewind/unwind control, metal strip tension control, textile machinery, and paper machines.

Its core objective is to maintain stable output torque regardless of speed variations.

Within vector control, torque control is inherently embedded.

For example: When a VFD is set to 25Hz but the feedback speed is only 24.9Hz, the system detects the speed error and automatically adjusts the torque component. By activating the VFD’s torque mode, it increases the output torque to restore stable speed.

In essence, speed control is ultimately achieved through torque control.

Therefore, it can be understood that:

- Torque control is one of the means to achieve vector control.

Visual Analogy: Cruise Control vs. Fixed Throttle

To intuitively grasp their relationship, consider this analogy:

- Vector Control: Like a car’s cruise control. The system automatically adjusts throttle (torque) to maintain constant speed regardless of terrain.

- Torque Control: Like holding the accelerator pedal steady. Torque remains constant, causing speed to decrease uphill and increase downhill.

This is precisely the core essence of the difference between the two control modes:

- Vector control maintains constant speed (speed regulation)

- Torque control maintains constant torque (torque regulation)

Conclusion: Selecting the Appropriate Control Mode

From an engineering practice perspective:

- When the system requires high-precision speed control (e.g., elevators, CNC, cranes), choose vector control.

- For systems requiring constant torque output (e.g., winding, tension control, extruders), select torque control.

- In high-performance VFDs, advanced algorithms like DTC vs. FOC VFD are also implemented to achieve faster response and reduced error.

Regardless of the control method chosen, understanding their objectives and principles is crucial for mastering VFD control modes explained and enhancing overall system efficiency and stability.