What is VFD Compressor? Working Principle & Retrofit Guide

By OULU Electric Engineering Team

Introduction

In industrial plants, compressors are often the undisputed energy hogs, consuming up to 40% of total facility electricity. Traditionally, these machines run at a fixed speed, using wasteful blow-off valves or inlet guide vanes to manage excess air or refrigerant.

At OULU Electric, we replace these outdated mechanical controls with intelligent motor-driven solutions. By integrating a Variable Frequency Drive, you stop making the motor run at full throttle when the demand is only 50%. This guide breaks down exactly what this technology is, how to apply it across different compressor types, and how to execute a successful retrofit.

Understanding the vfd compressor meaning

To define the vfd compressor meaning, you must look at the electrical input. A VFD compressor is simply a standard compressor mechanism (screw, scroll, or piston) powered by an AC induction or permanent magnet motor that is controlled by a Variable Frequency Drive.

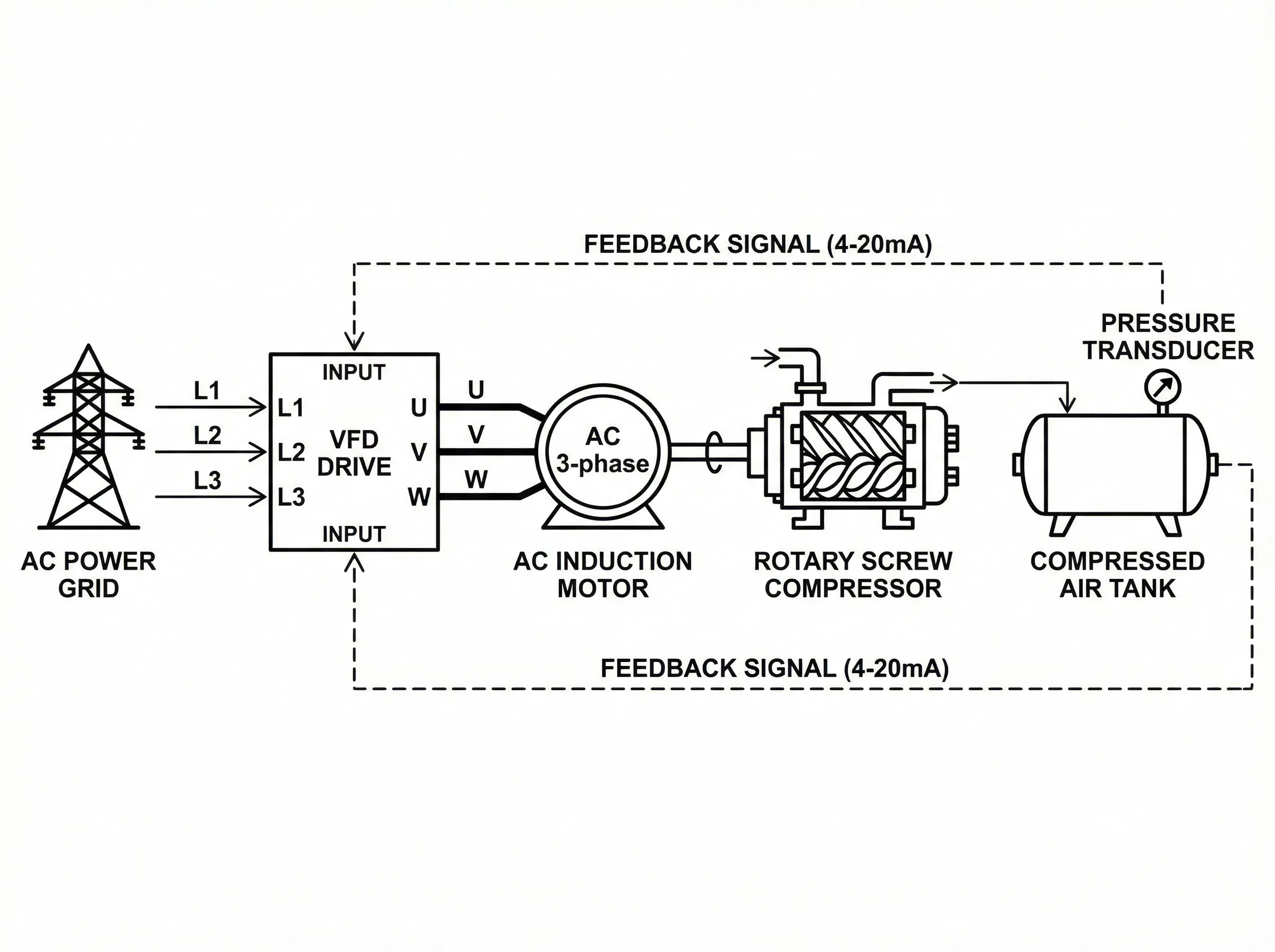

The vfd compressor full form stands for Variable Frequency Drive Compressor. Instead of connecting the motor directly to the 3-phase power grid (which forces it to run at a fixed 50Hz or 60Hz), the drive sits between the grid and the motor, acting as an energy-metering gateway.

Exploring the vfd compressor working principle

The vfd compressor working principle is based on the direct mathematical relationship between electrical frequency and motor speed. By converting incoming AC power to DC, and then inverting it back into a synthetic AC wave at a precise frequency, the drive dictates the exact RPM of the motor. If your facility needs less compressed air, the drive lowers the frequency, the motor slows down, and the vfd compressor working state matches the exact pneumatic or thermodynamic load.

Intelligent vfd compressor control

Modern vfd compressor control relies on closed-loop feedback. A pressure transducer in the air receiver tank or refrigeration line sends a 4-20mA signal to the drive’s analog input. Using a built-in PID controller, the drive continuously adjusts the motor speed to maintain a perfectly flat, constant pressure profile without human intervention.

vsd vs vfd compressor: Understanding the difference

We often hear clients ask about the difference between vfd and vsd compressor systems.

- VSD (Variable Speed Drive): This is a broad umbrella term. A VSD can be mechanical (like hydraulic clutches), DC motor-driven, or AC motor-driven.

- VFD (Variable Frequency Drive): This is a specific type of VSD that strictly controls AC motor speed by altering the electrical frequency (Hz). Therefore, in a vsd vs vfd compressor comparison, every VFD is a VSD, but not every VSD is a VFD. In modern industrial applications, almost all electronic speed controllers are VFDs.+1

Key benefits of vfd compressor systems

The benefits of vfd compressor installations go far beyond basic energy savings:

- Massive Energy Reduction: Operating a compressor at 80% speed uses significantly less power than running it at 100% and bleeding off the excess air.

- Elimination of Inrush Current: VFDs provide a “soft start,” slowly ramping up the voltage. This prevents massive current spikes that cause voltage drops and stress the electrical grid.

- Mechanical Longevity: Starting at zero RPM and ramping up eliminates the violent mechanical shock on belts, couplings, and bearings.

- Precise Pressure Control: Eliminates the wide pressure swings (cut-in/cut-out bands) associated with traditional fixed-speed setups.

Industrial vfd compressor application Guide

Not all compressors behave the same electrically. Selecting the right drive depends heavily on the mechanical physics of the vfd compressor application.

Standard vfd air compressor setups

For standard vfd air compressors, we typically use a vfd for 3 phase air compressor setup. A vfd based air compressor provides steady plant air, eliminating the loud, wasteful load/unload cycles.

Optimizing the vfd screw compressor vs. vfd scroll compressor

- vfd screw air compressor: A rotary screw compressor is a Constant Torque load. It requires heavy pushing power across its entire speed range. You must use a Heavy-Duty rated drive (like the OULU G-Type, allowing 150% overload).

- vfd scroll compressor: Scroll compressors require less starting torque and are highly efficient for medium-duty vfd driven compressor applications.

Using a vfd for reciprocating compressor

Applying a vfd for reciprocating compressor (piston type) is challenging but possible. Piston compressors have massive starting inertia and pulsating torque profiles. You need an oversized VFD to handle the aggressive starting spikes, and you must adhere to minimum speed limits to ensure splash lubrication inside the crankcase still functions.

Modern vfd hvac compressor and vfd chiller compressor

In large facilities, a vfd chiller compressor adjusts the cooling capacity to match the building’s heat load. Implementing a vfd hvac compressor ensures that the chiller doesn’t short-cycle during spring and autumn when cooling demands are low.

Commercial vfd refrigeration compressor setups

In food processing and cold storage, a vfd compressor refrigeration system is critical. A vfd refrigeration compressor maintains precise evaporator temperatures, preventing frost buildup and reducing product spoilage.

Installing a vfd for ac compressor

For smaller or localized cooling, retrofitting a vfd for ac compressor (including a vfd for home ac compressor or putting a vfd on ac compressor circuits) smooths out temperature fluctuations and dramatically drops the cooling power bill.

air compressor vfd retrofit and vfd compressor price

Do you need to buy a brand new machine? Not always. An air compressor vfd retrofit allows you to mount a control panel next to your existing fixed-speed compressor. The vfd compressor price varies based on the kilowatt (kW) rating and enclosure type. However, for a 50HP to 100HP system, the hardware cost is usually recovered rapidly through energy savings.

Try our air compressor vfd energy savings calculator

Before upgrading, engineers use an air compressor vfd energy savings calculator. By logging your current load/unload times and electrical rates, we can project exactly how many months it will take for the VFD to pay for itself.

Troubleshooting a vfd compressor fault

When a vfd compressor fault occurs, the drive protects the motor. Common faults include Overcurrent (FU01) during rapid acceleration, or Overvoltage (FU02) if the compressor forces the motor to decelerate too quickly without a braking resistor.

How to reset a vfd compressor lockout

A vfd compressor lockout happens when the drive registers multiple severe faults (like a dead short or extreme thermal overload). To reset:

- Isolate the power.

- Check the compressor air end to ensure it is not mechanically jammed.

- Check the motor windings with a megger.

- Once cleared, clear the fault code via the VFD keypad to lift the safety lockout.

Frequently Asked Questions (FAQ)

What is the difference between VFD and VSD compressor?

A VSD (Variable Speed Drive) is a general term for any device that changes motor speed, including mechanical or DC drives. A VFD (Variable Frequency Drive) is a specific electronic type of VSD that controls the speed of an AC motor by altering the frequency (Hz) of the electrical supply.+1

What does VFD stand for?

VFD stands for Variable Frequency Drive.

Can you use a VFD on an air compressor?

Yes, but you must ensure the motor is “inverter-duty” rated to handle the synthetic AC waveforms and reduced cooling at low speeds. You must also properly size the VFD for the heavy, constant-torque load of the compressor air-end.

How to tell if a compressor is variable speed?

Look at the control panel. If it has a digital screen displaying frequency (Hz) or RPM, and lacks traditional mechanical magnetic contactors for direct-on-line starting, it is likely variable speed. You will also notice the motor gradually ramping up and down in pitch, rather than turning on and off abruptly.

What are the three types of compressors?

The three primary mechanical types used in industrial settings are:

- Rotary Screw Compressors: Continuous flow, ideal for VFDs.

- Reciprocating (Piston) Compressors: Pulsating flow, difficult to pair with VFDs due to high starting torque.

- Centrifugal Compressors: Dynamic, high-volume flow, often used in massive industrial plants.

How do i use an air compressor?

Check the oil level (if applicable), connect your air hose and tools, plug the unit into the correct power supply, and turn the pressure switch to “Auto.” Use the output regulator to set the specific PSI required for your pneumatic tool, never exceeding the tool’s maximum rating.

How long does air conditioner compressor last?

A standard fixed-speed air conditioner compressor typically lasts 10 to 15 years with proper maintenance. VFD-driven AC compressors can often last longer because the soft-starting feature eliminates the violent mechanical stress and heat buildup associated with constant on/off cycling.

What is the air compressor used for?

It is used to convert electrical energy into potential energy stored in pressurized air. This compressed air is then used to power pneumatic tools (drills, nail guns), operate automated manufacturing valves/cylinders, spray paint, or drive HVAC control systems.